Angle type tension control method and device for stable conveying of carbon fiber prepreg tape

A technology of carbon fiber prepreg and tension control, which is applied in the direction of transportation and packaging, sending objects, winding strips, etc., to achieve the effect of increasing the buffer distance, occupying less space, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings.

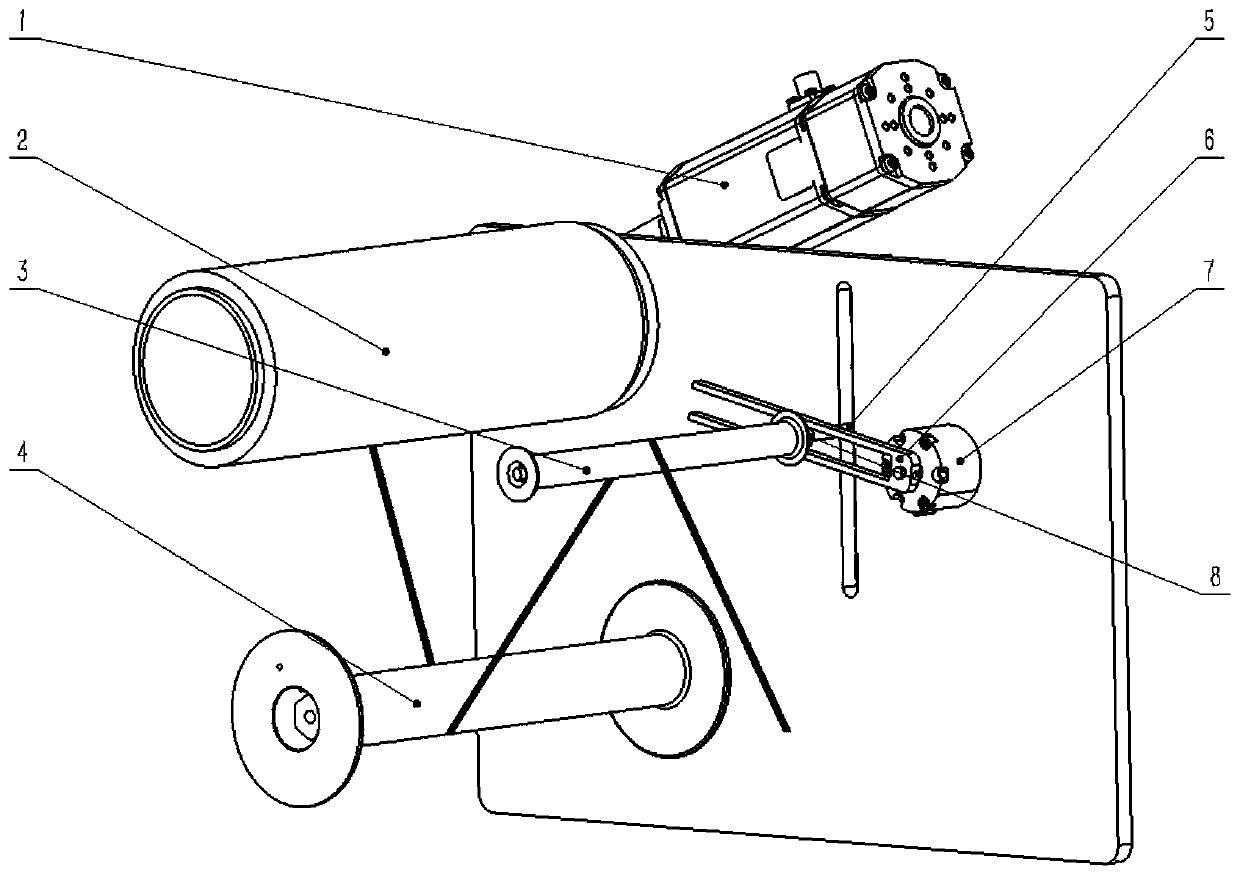

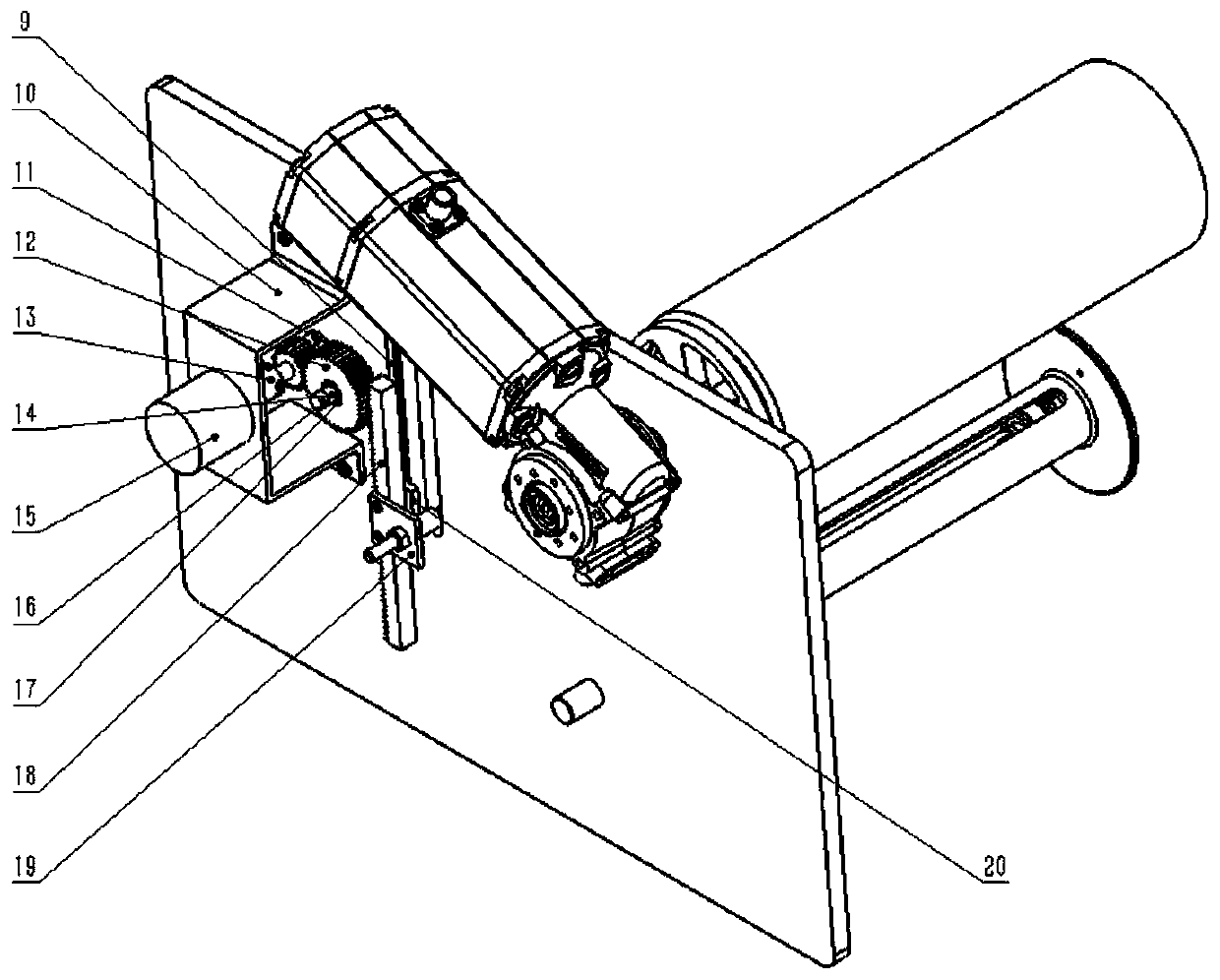

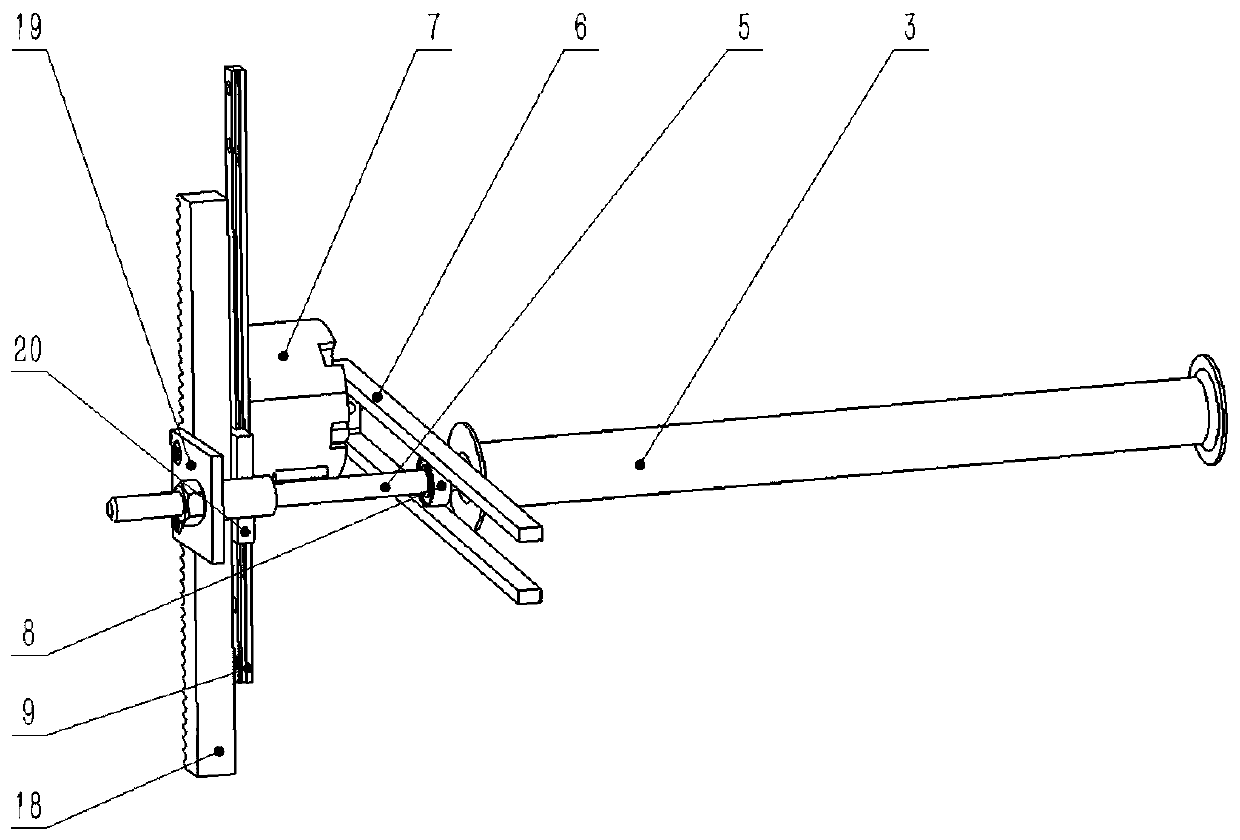

[0030] see figure 1 , an angle-type tension control device for stable delivery of carbon fiber prepreg tape according to the present invention, comprising an unwinding motor 1, a backing paper collection roller 4, a swing lever mechanism, a tension buffer mechanism, an angle amplification mechanism and an angle detection mechanism; Among them, the material roll 2 is connected with the unwinding motor 1, and the carbon fiber prepreg tape on the material roll 2 is actively released by the unwinding motor 1, bypassing the backing paper collection roller 4 to realize the separation of the prepreg tape and the backing paper, and then through The pendulum mechanism enters the tension buffer mechanism to realize tension regulation.

[0031] The fork mechanism includes a rotary cylinder 7, a fork 6 and a set screw. The rotary cylinder 7 is fixed on the frame, and the swing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com