Aramid nanofiber/polyvinyl alcohol/polyaniline composite hydrogel and preparation method and application thereof

A composite hydrogel and nanofiber technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measurement devices, etc., can solve the problems of lack of research, achieve high strain sensitivity, improve mechanical properties, and high toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

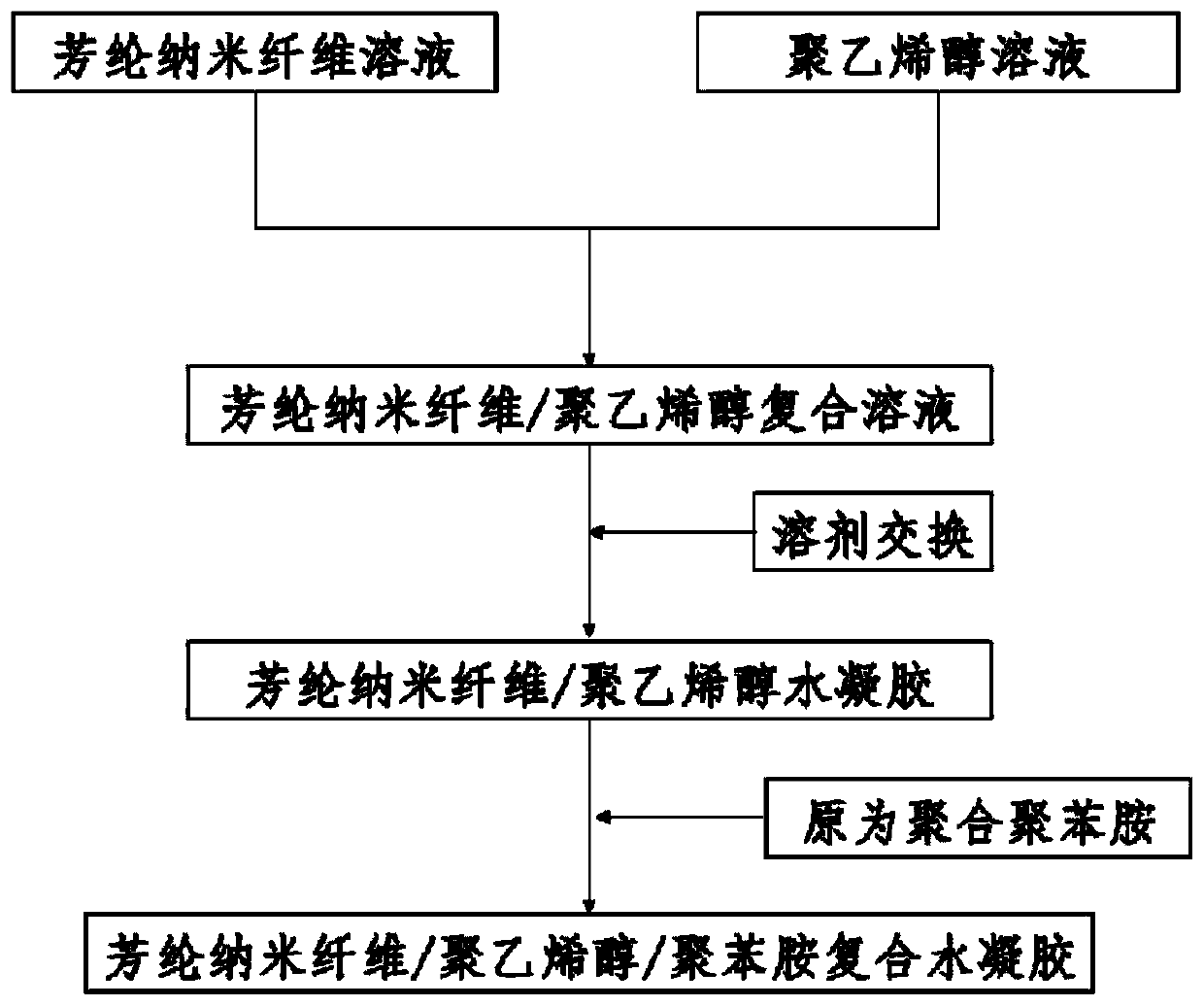

Method used

Image

Examples

Embodiment 1

[0030] Weigh 1 g of Kevlar spun fiber and 1.5 g of KOH, add DMSO, and stir at room temperature for four weeks to obtain a 20 mg / mL aramid nanofiber solution.

[0031] Weigh 5 g of polyvinyl alcohol with a molecular weight of 145,000 to 165,000, add DMSO, fully swell at room temperature, then dissolve at a high temperature of 90 to 95°C until it is completely transparent, and stand until the bubbles completely disappear to obtain a 100 mg / mL PVA solution.

[0032] Mix an equal volume of 20mg / mL aramid nanofiber solution and 100mg / mL PVA solution (mass ratio ANF:PVA=1:5) at 60°C for 4 hours; the resulting mixed system was dried in vacuum Dry in the oven to remove excess solvent and control the solids content to 10%.

[0033] The above mixed system was cast in a mold, and then immersed in water for solvent exchange for 24 hours to form an ANF / PVA hydrogel with a specific geometric shape.

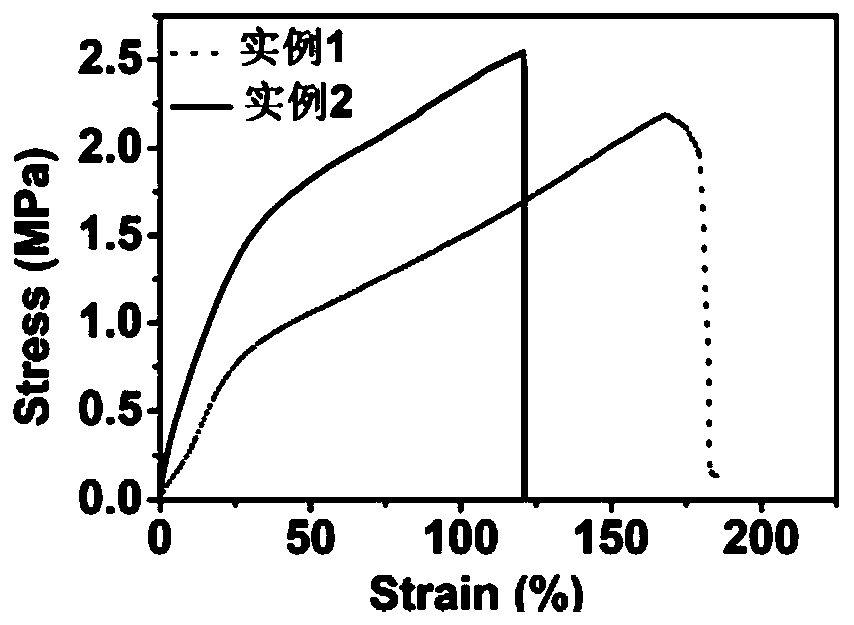

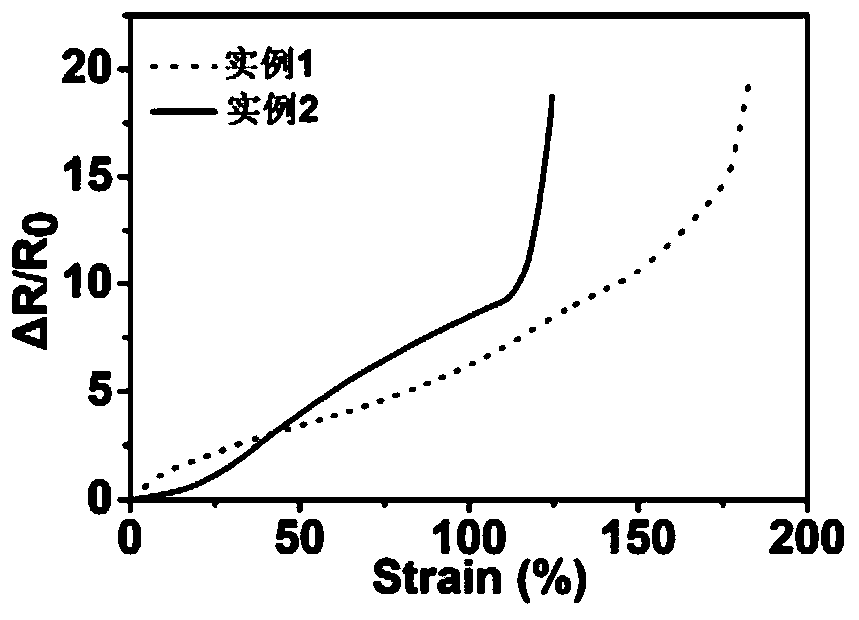

[0034] Cut the ANF / PVA hydrogel to a size of 1×3cm 2 , and place it in 20 mL of 1M hydroc...

Embodiment 2

[0036] Weigh 1 g of Kevlar spun fiber and 1.5 g of KOH, add DMSO, and stir at room temperature for four weeks to obtain a 20 mg / mL aramid nanofiber solution.

[0037] Weigh 5 g of polyvinyl alcohol with a molecular weight of 145,000 to 165,000, add DMSO, fully swell at room temperature, then dissolve at a high temperature of 90 to 95°C until it is completely transparent, and stand until the bubbles completely disappear to obtain a 100 mg / mL PVA solution.

[0038] Mix an equal volume of 20mg / mL aramid nanofiber solution and 100mg / mL PVA solution (mass ratio ANF:PVA=1:5) at 50°C for 6 hours; the resulting mixed system was dried in vacuum Dry in the oven to remove excess solvent and control the solids content to 15%.

[0039] The above mixed system was cast in a mold, and then immersed in water for solvent exchange for 24 hours to form an ANF / PVA hydrogel with a specific geometric shape.

[0040] Cut the ANF / PVA hydrogel to a size of 1×3cm 2 , and place it in 20 mL of 1M hydroc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com