Flame retardant coating and flame retardant fabric

A technology of flame retardant coatings and flame retardant fabrics, applied in fire retardant coatings, polyurea/polyurethane coatings, coatings, etc., can solve problems such as inability to protect sofas, sofa impact, etc., and achieve excellent mechanical properties and weather resistance, Long service life and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

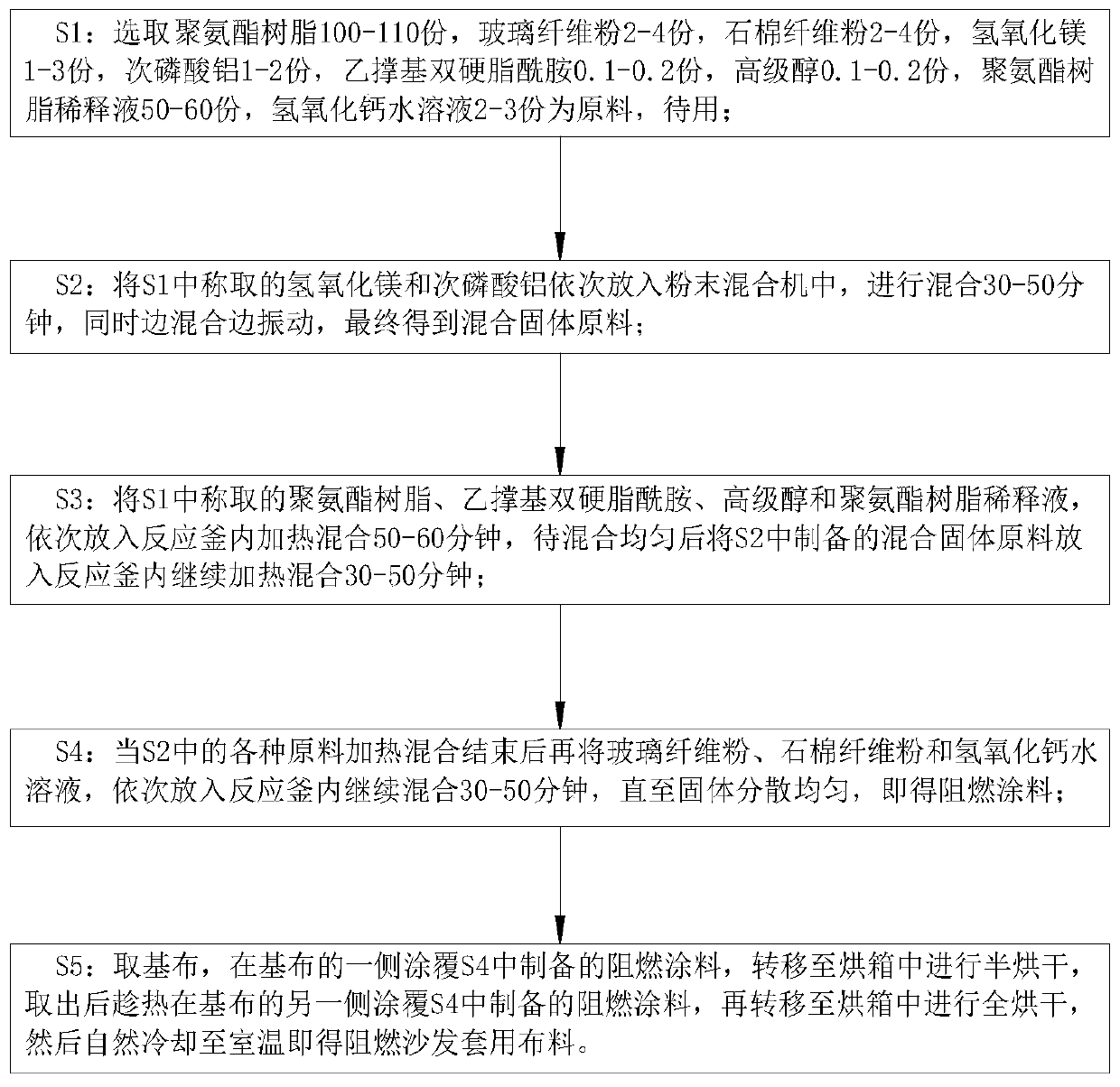

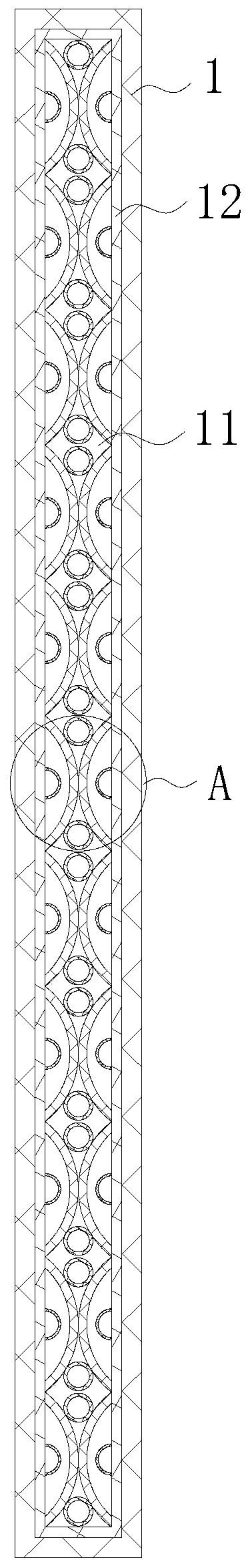

[0037] Such as Figure 1-Figure 4 Shown, a kind of flame retardant coating of the present invention, the preparation method of this flame retardant coating comprises the following steps:

[0038] S1: Choose 100-110 parts of polyurethane resin, 2-4 parts of glass fiber powder, 2-4 parts of asbestos fiber powder, 1-3 parts of magnesium hydroxide, 1-2 parts of aluminum hypophosphite, 0.1 parts of ethylene bis stearamide -0.2 parts, 0.1-0.2 parts of higher alcohol, 50-60 parts of polyurethane resin diluent, 2-3 parts of calcium hydroxide aqueous solution as raw materials, stand-by;

[0039] S2: Put the magnesium hydroxide and aluminum hypophosphite weighed in S1 into a powder mixer in turn, mix for 30-50 minutes, and vibrate while mixing, and finally obtain a mixed solid raw material;

[0040] S3: Put the polyurethane resin, ethylene bisstearamide, higher alcohol and polyurethane resin diluent weighed in S1 into the reaction kettle and heat and mix for 50-60 minutes. Put the raw...

Embodiment approach

[0051] As an embodiment of the present invention, the raw material further includes a flame retardant, and the flame retardant is an inorganic flame retardant.

[0052] The inorganic flame retardant selected in the raw material is composed of high-temperature resistant solution and finely processed ultrafine inorganic metal oxides. The temperature resistance can reach 1700 ° C. It has no odor at room temperature and high temperature. The coating film will not be affected after the inorganic flame retardant is applied. The original color of the object, the inorganic flame retardant is painted on the inorganic material substrate, can form an interpenetrating network structure with the surface of the object, has good adhesion, and has a certain protective effect of heat insulation, anti-oxidation, anti-corrosion, flame retardant and fire prevention. The service life of the substrate is prolonged, energy saving and environmental protection are achieved, thereby greatly improving th...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap