Method for solid-phase synthesis of green fluorescent perovskite

A green fluorescence, solid-phase synthesis technology, applied in chemical instruments and methods, lead compounds, luminescent materials, etc., can solve the problems of specific solvents and complex ligands, final cost increase, etc., to achieve short time consumption and simple synthesis methods. , the effect of easy availability of synthetic raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

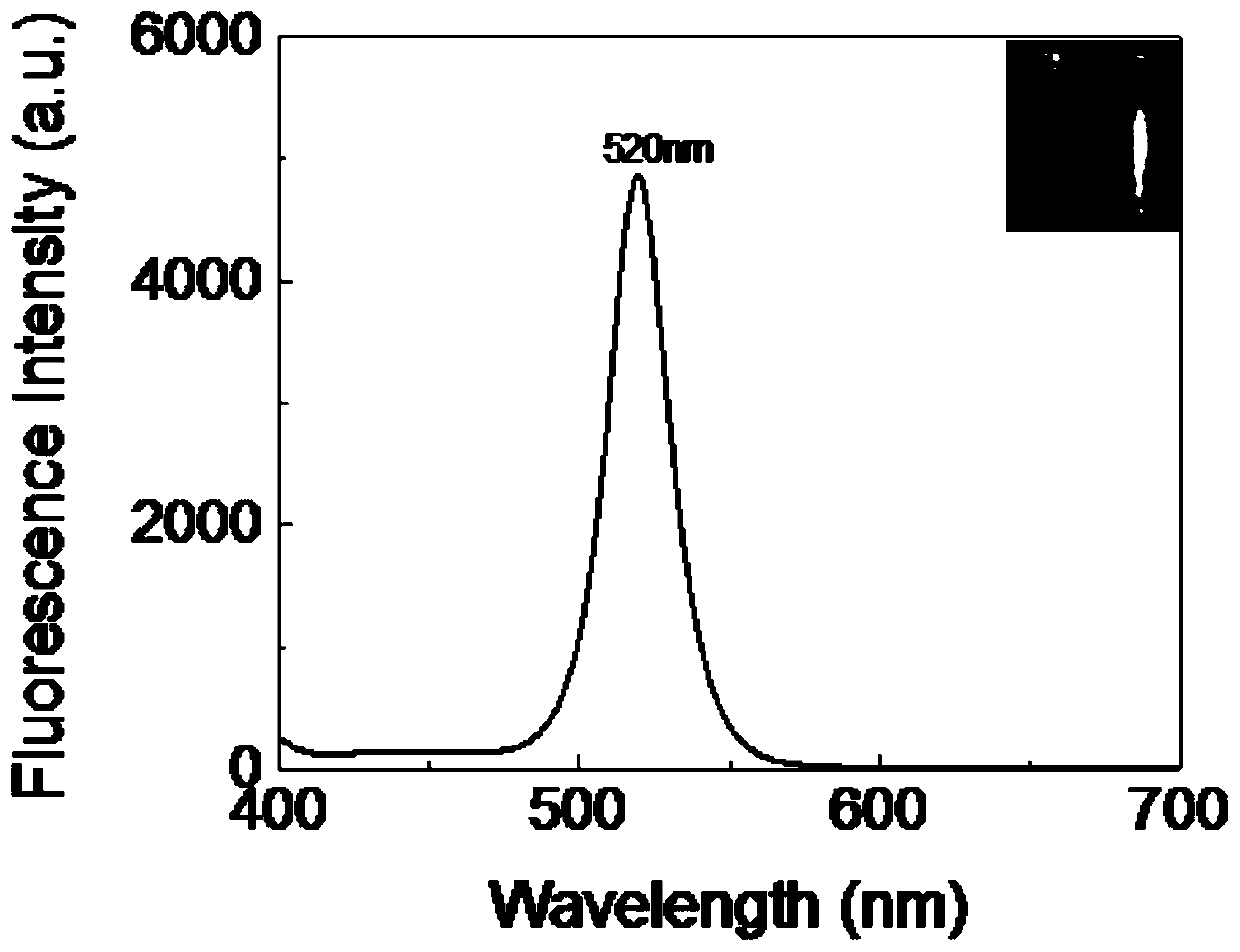

[0020] Embodiment 1: a kind of method of solid phase synthesis green fluorescent perovskite, concrete steps are as follows:

[0021] (1) Mix lysine, cesium bromide, and lead bromide evenly to obtain a mixed powder; wherein the molar ratio of cesium bromide, lysine, and lead bromide is 1:0.2:1;

[0022] (2) Put the mixed powder in a centrifuge tube, then protect the centrifuge tube from light, place the light-proof centrifuge tube in a vortex mixer for oscillating and mixing reaction for 25 minutes, and then place it in the dark for 10 minutes to obtain green fluorescent CsPbBr 3 Material; Wherein the rotating speed of vortex mixer is 3000r / min;

[0023] The present embodiment green fluorescent CsPbBr 3 Material reaction principle: In the synthesis of solution-based colloidal nanocrystals, the key lies in the use of capped ligands to obtain nanocrystals with high emission through solvent-induced reprecipitation; the role of these ligands is to provide crystallized self- Termi...

Embodiment 2

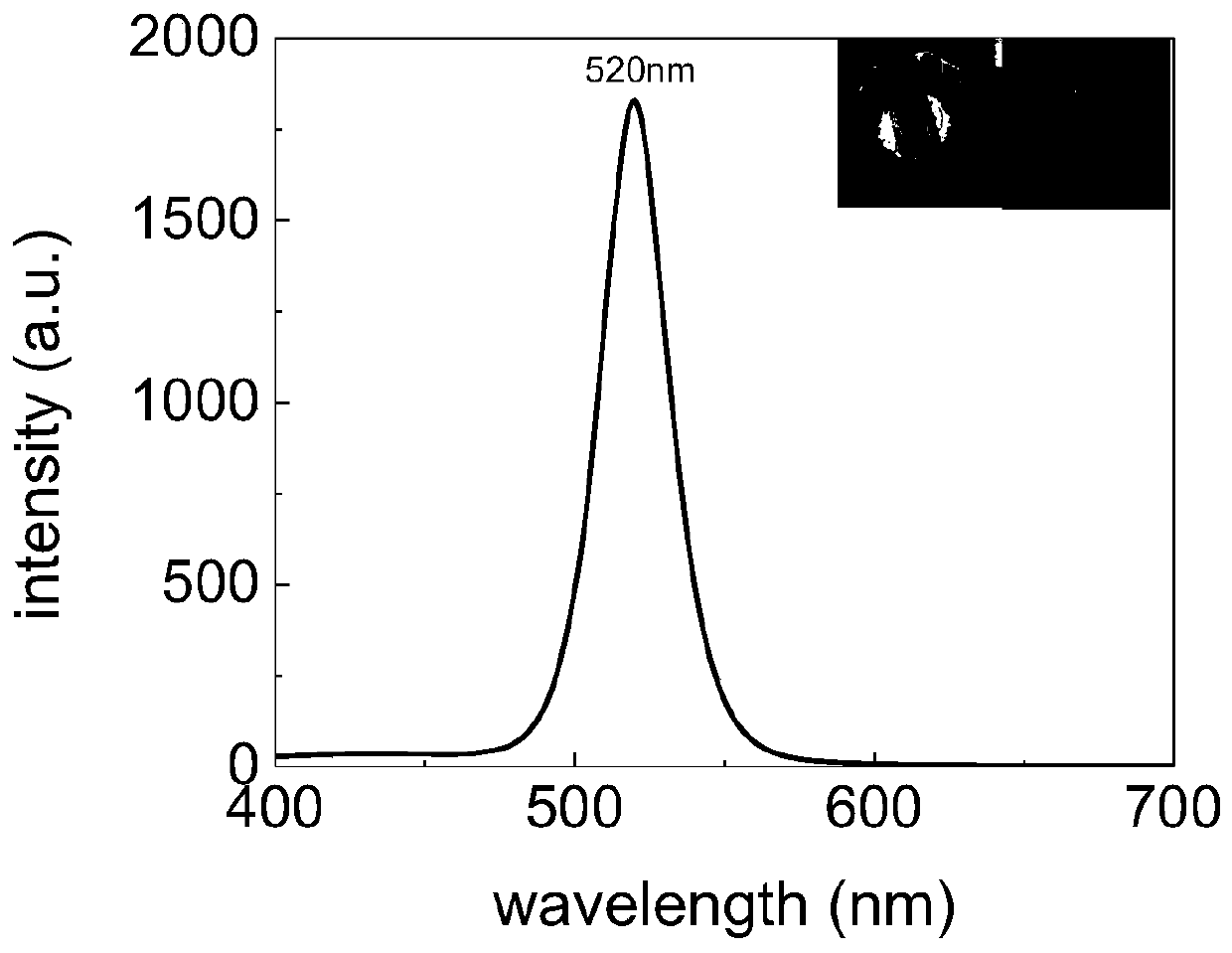

[0027] Embodiment 2: a kind of method of solid phase synthesis green fluorescent perovskite, concrete steps are as follows:

[0028] (1) Mix lysine, cesium bromide, and lead bromide evenly to obtain a mixed powder; wherein the molar ratio of cesium bromide, lysine, and lead bromide is 1:0.08:0.26;

[0029] (2) Put the mixed powder in a centrifuge tube, and then protect the centrifuge tube from light, place the light-proof centrifuge tube in a vortex mixer for 1 minute of oscillating mixing reaction, and then place it in the dark for 5 minutes to obtain green fluorescent CsPbBr 3 Material; Wherein the rotating speed of vortex mixer is 3000r / min;

[0030] The present embodiment green fluorescent CsPbBr 3 The maximum fluorescence emission wavelength of the material is 520nm; the present embodiment green fluorescent CsPbBr 3 Material about 250nm, CsPbBr 3 It is wrapped in lysine to form a spherical structure; the green fluorescent CsPbBr in this example 3 After the material is...

Embodiment 3

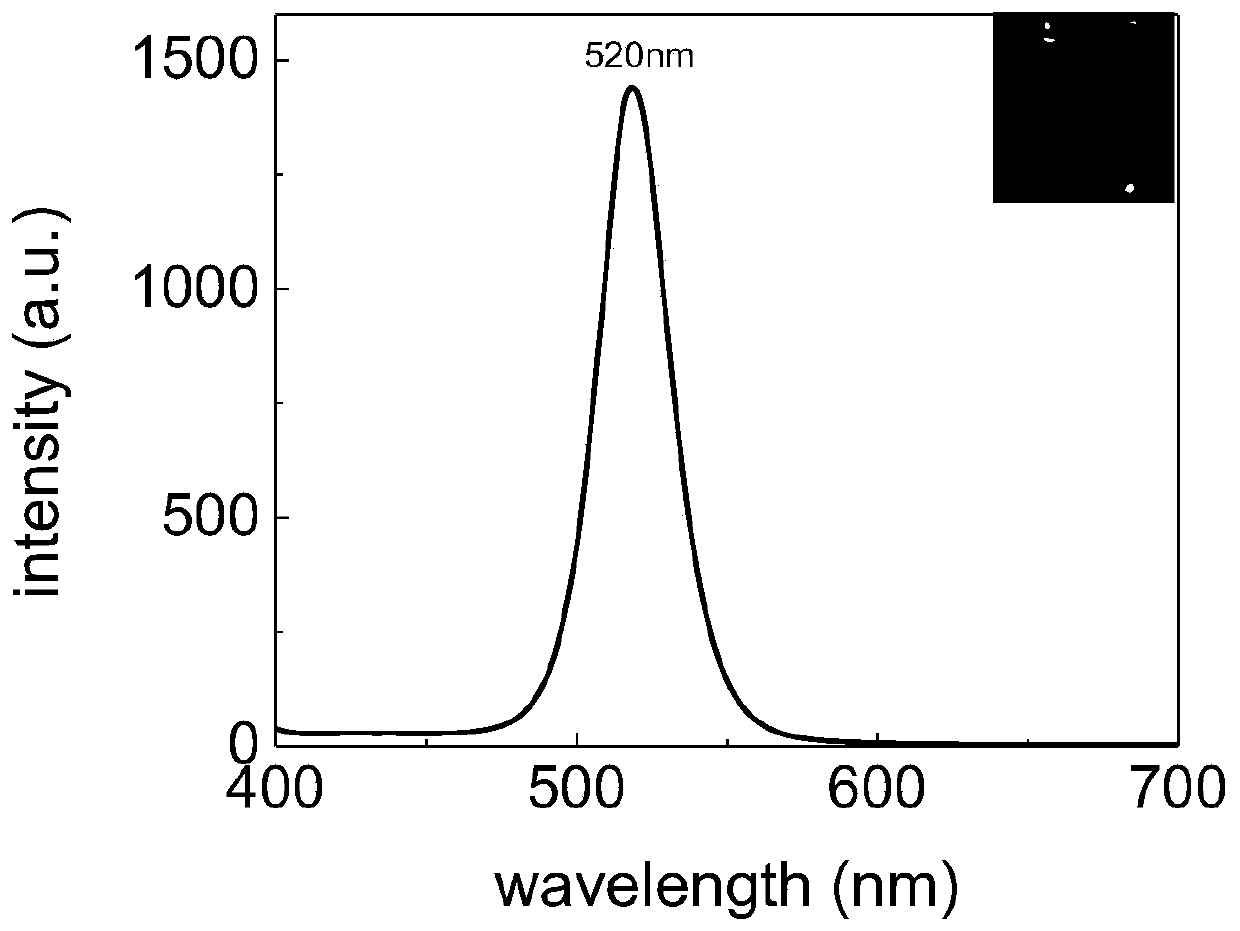

[0031] Embodiment 3: a kind of method of solid phase synthesis green fluorescent perovskite, concrete steps are as follows:

[0032] (1) Mix lysine, cesium bromide, and lead bromide evenly to obtain a mixed powder; wherein the molar ratio of cesium bromide, lysine, and lead bromide is 1:3.5:10;

[0033] (2) Put the mixed powder in a centrifuge tube, and then protect the centrifuge tube from light, place the light-proof centrifuge tube in a vortex mixer for 25 minutes of shaking and mixing reaction, and then place it in the dark for 5 minutes to obtain green fluorescent CsPbBr 3 Material; Wherein the rotating speed of vortex mixer is 3000r / min;

[0034] The present embodiment green fluorescent CsPbBr 3 The maximum fluorescence emission wavelength of the material is 520nm; the present embodiment green fluorescent CsPbBr 3 Material about 250nm, CsPbBr 3 It is wrapped in lysine to form a spherical structure; the green fluorescent CsPbBr in this example 3 After the material is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com