Method for preparing lead-acid battery lead paste

A technology of lead-acid battery and lead paste, which is applied in the direction of lead-acid battery electrodes, battery electrodes, circuits, etc. It can solve the problems of softening, falling off, and no shearing force of the active material of the lead paste, so as to improve dry mixing. Efficiency, efficiency improvement, effect of fiberization degree improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

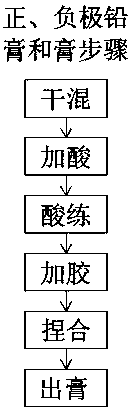

[0029] Please refer to figure 1 , the present invention provides a technical solution: a method for preparing lead-acid battery lead paste, including a positive electrode paste and paste method and a negative electrode paste and paste method, characterized in that: the formula of the positive lead paste: lead powder as the main raw material , polytetrafluoroethylene, red lead, anisotropic graphite, antimony trioxide, etc. as additives; the formula of negative lead paste: lead powder as the main raw material, polytetrafluoroethylene, lignin, acetylene black, barium sulfate, etc. additive.

[0030] Positive lead paste and paste steps are as follows:

[0031] S1, dry mixing, put lead powder, red lead, anisotropic graphite, antimony trioxide and other raw materials into a conical high-speed mixer for mixing, stirring speed 500~1000 rpm, stirring time 5~8 minutes;

[0032] S2, add acid, put the above mixed powder into the kneader, add the sulfuric acid solution using a sprayer, ...

Embodiment 1

[0046] Positive lead paste and paste steps are as follows:

[0047] S1, dry mixing, put 100 parts of lead powder, 5 parts of red lead, 0.2 parts of anisotropic graphite and 0.2 parts of antimony trioxide into a conical high-speed mixer for mixing, the stirring speed is 1000 rpm, and the stirring time is 5 minutes;

[0048] S2, add acid, put the above mixed powder into the kneader, use a sprayer to add 1.14g / cm 3 22 parts of sulfuric acid solution, kneading while adding, the kneading speed is 40 rpm, and the sulfuric acid solution is added within 5 minutes;

[0049] S3, acid refining, continue kneading for 10 minutes after adding the sulfuric acid solution, the kneading speed is 40 rpm;

[0050] S4, adding glue, using a sprayer to add 0.8 parts of 60% polytetrafluoroethylene emulsion, kneading while adding, the kneading speed is 20 rpm, and the polytetrafluoroethylene emulsion is added within 2 minutes;

[0051] S5, kneading, continue kneading for 2 minutes, kneading speed 20...

Embodiment 2

[0062] Positive lead paste and paste steps are as follows:

[0063] S1, dry mixing, put 100 parts of lead powder, 5 parts of red lead, 0.2 part of anisotropic graphite and 0.2 part of antimony trioxide into a conical high-speed mixer and mix at a stirring speed of 800 rpm for 5 minutes;

[0064] S2, add acid, put the above mixed powder into the kneader, use a sprayer to add 1.14g / cm 3 22 parts of sulfuric acid solution, kneading while adding, the kneading speed is 40 rpm, and the sulfuric acid solution is added within 5 minutes;

[0065] S3, acid refining, continue kneading for 10 minutes after adding the sulfuric acid solution, the kneading speed is 40 rpm;

[0066] S4, adding glue, using a sprayer to add 2 parts of 60% polytetrafluoroethylene emulsion, kneading while adding, the kneading speed is 20 rpm, and the polytetrafluoroethylene emulsion is added within 2 minutes;

[0067] S5, kneading, continue kneading for 2 minutes, kneading speed 20 rpm;

[0068] S6, dispensing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com