Vermicelli gelatinizing, cooling and sectioning complete equipment and application method

A complete set of device and technology for vermicelli, applied in the fields of application, food forming, food science, etc., can solve the problems of increasing the manufacturing cost of vermicelli, low degree of automation, high labor intensity, and reduce the drawing rate and breaking rate, and the degree of automation. High, improve the effect of finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

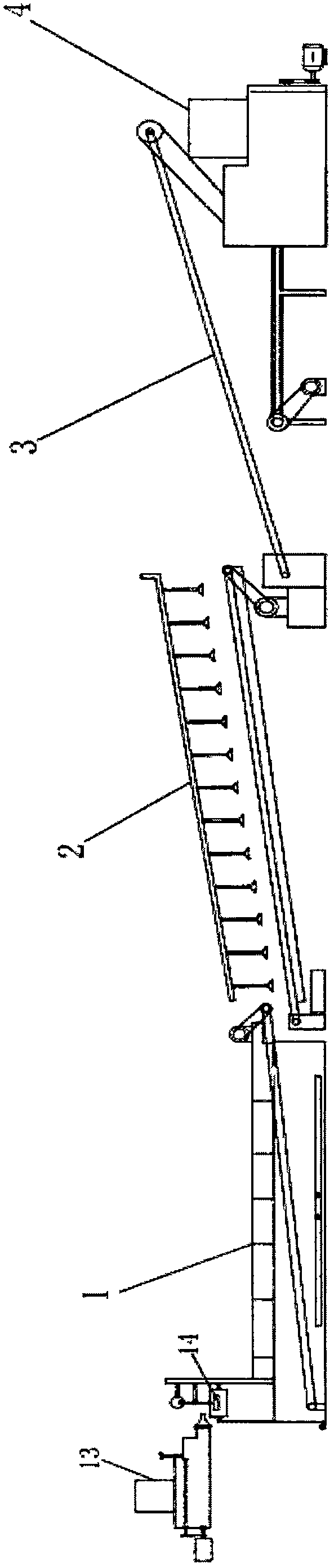

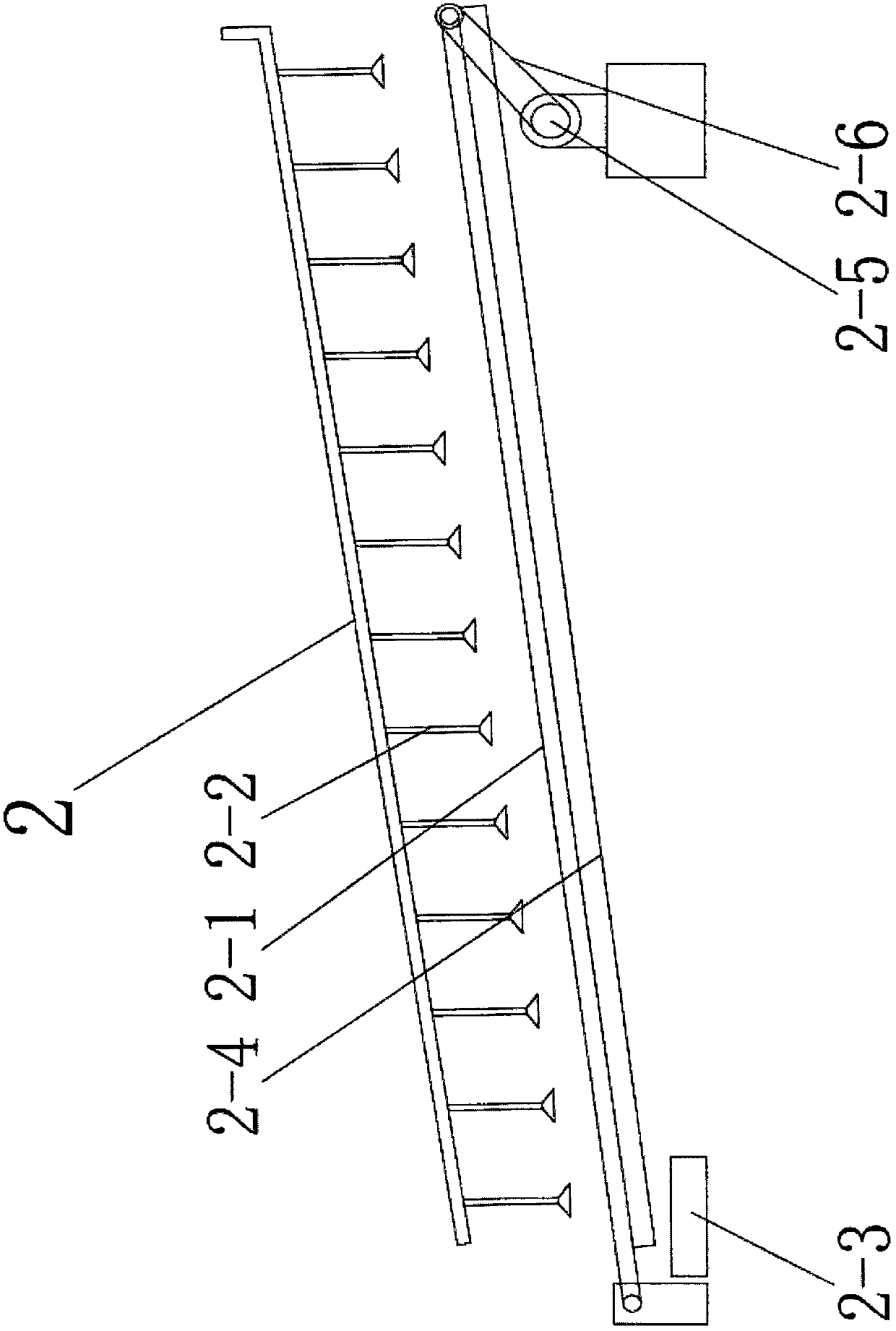

[0044] A complete set of equipment for pasting, cooling and cutting of vermicelli, such as figure 1 As shown, it is composed of a gelatinization system 1, a cooling system 2, a lifting conveyor belt 3, and a cutting system 4, and a starch mud mixer 13 and a vermicelli extruding powder leakage machine 14 are installed in the front section of the gelatinization system 1, and the starch mud mixer The starch paste produced in 13 enters the vermicelli extruding and leaking machine 14 to make vermicelli, then enters the gelatinization system 1 for gelatinization, cooling system 2 for cooling and evacuation, and finally sends it to the cutting system 4 through the lifting conveyor belt 3 for further processing. Cut into sections, and integrate powder slag and water recovery into one;

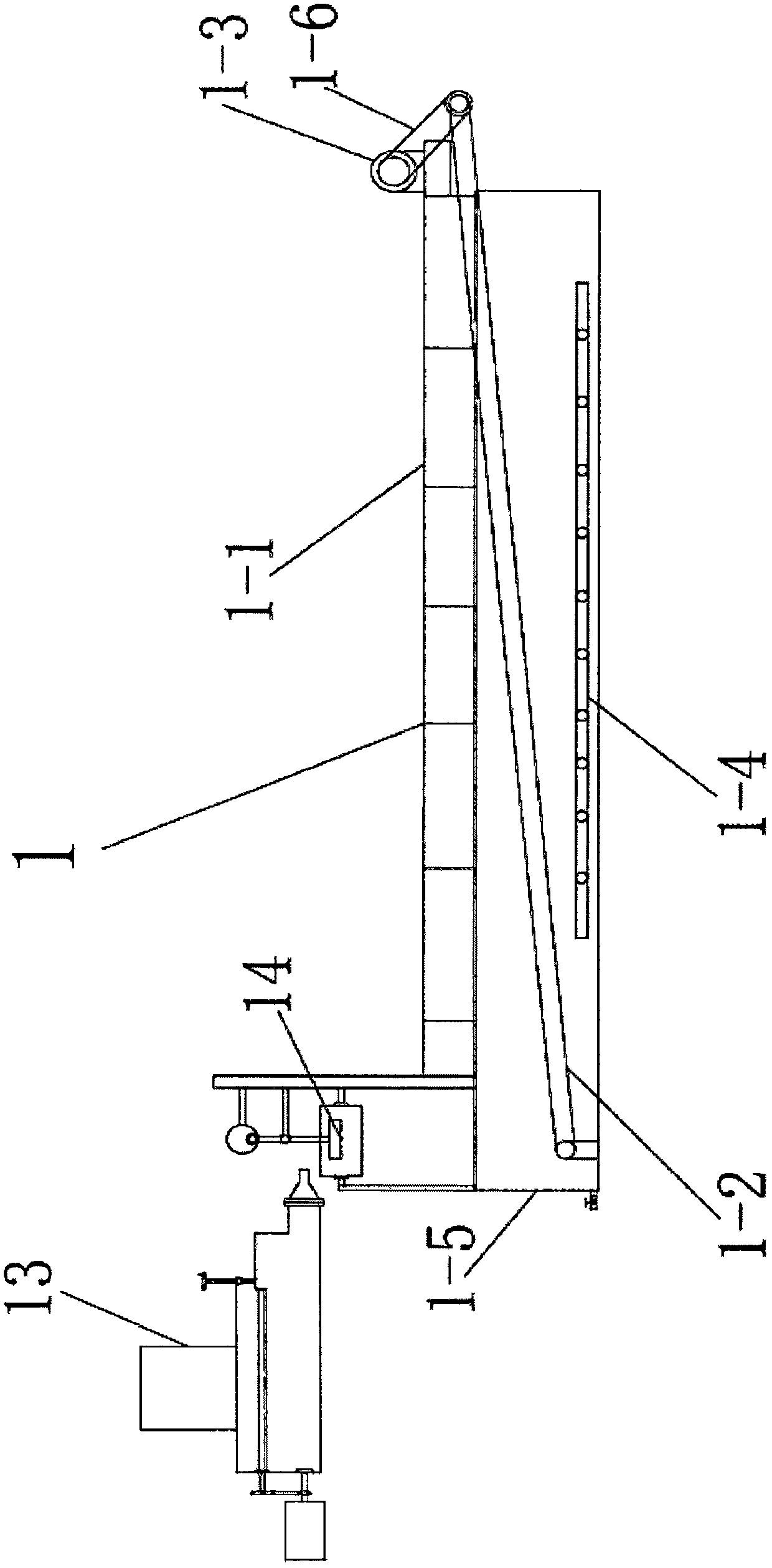

[0045] Such as figure 2 As shown, the gelatinization system 1 is made up of a pool 1-5 and a conveyor belt 1-2, the pool 1-5 is used to store cooking water, and the vermicelli on the conveyor belt 1-...

Embodiment 2

[0066] The application method of the complete set of equipment for gelatinizing, cooling and cutting vermicelli, using the complete set of equipment for gelatinizing, cooling and cutting vermicelli, using sweet potato starch as raw material to prepare vermicelli, including the following steps:

[0067] (1) Vermicelli

[0068] The sweet potato starch is made into starch mud through the starch mud mixer 13, and then the starch mud is continuously extruded into vermicelli through the vermicelli extruding powder leakage machine 14;

[0069] (2) Gelatinization

[0070] First put water in the pool 1-5 of the gelatinization system 1, heat and control the water temperature to 92°C, then drop the vermicelli extruded in step (1) onto the conveyor belt 1-2 in the pool 1-5, and the vermicelli The gelatinization time in the pool 1-5 is controlled at 5 minutes, the conveying speed of the conveyor belt 1-2 matches the gelatinization time of the vermicelli in the pool 1-5, and is continuously ...

Embodiment 3

[0078] The application method of the complete set of equipment for gelatinizing, cooling and cutting vermicelli, using the complete set of equipment for gelatinizing, cooling and cutting vermicelli, using sweet potato starch as raw material to prepare vermicelli, including the following steps:

[0079] (1) Vermicelli

[0080] The sweet potato starch is made into starch mud through the starch mud mixer 13, and then the starch mud is continuously extruded into vermicelli through the vermicelli extruding powder leakage machine 14;

[0081] (2) Gelatinization

[0082] First put water in the pool 1-5 of the gelatinization system 1, heat and control the water temperature to 93°C, then drop the vermicelli extruded in step (1) onto the pool, on the conveyor belt 1-2 in 1-5, The gelatinization time of the vermicelli in the pool 1-5 is controlled at 4 minutes, the conveying speed of the conveyor belt 1-2 matches the gelatinization time of the vermicelli in the pool 1-5, and is continuo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com