A kind of brass alloy and its production method

A brass alloy and production method technology, applied in the field of metal materials, can solve the problems of difficulty in the utilization of sub-brands, waste of zinc elements, and high process costs, and achieve the effects of excellent weather resistance, excellent durability and low material cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

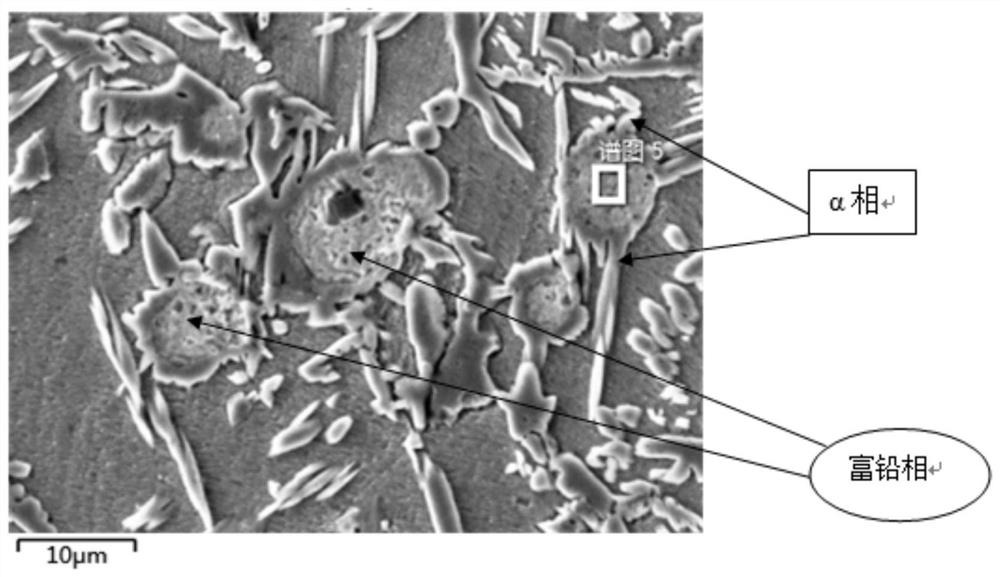

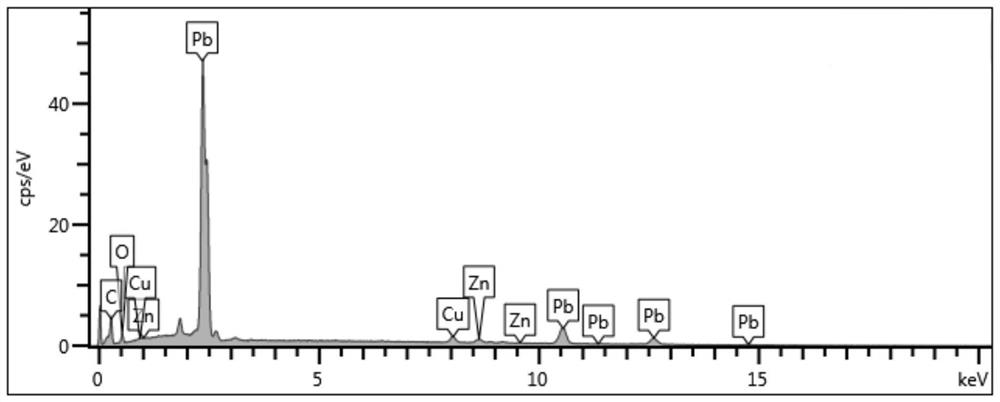

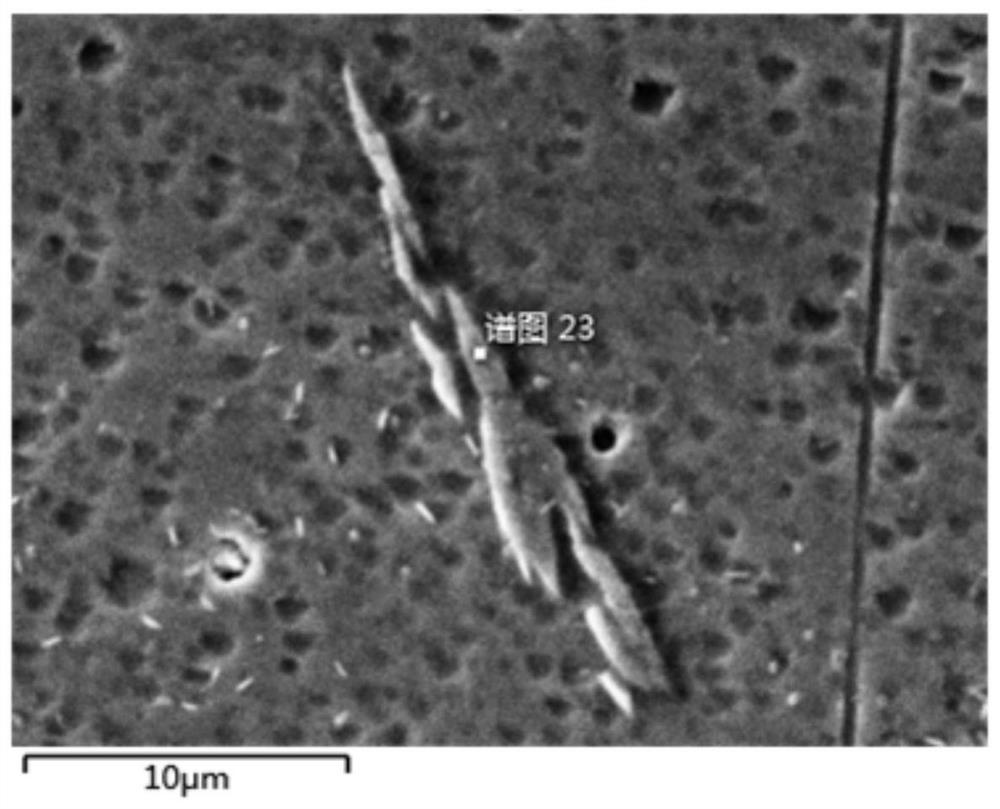

[0048] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0049] Choose 4 embodiment brass alloys, take recycled raw material as raw material, adopt the inventive method to produce artwork, specifically comprise the following steps:

[0050] (1) Raw material pretreatment

[0051] a) Magnetic separation and elutriation of yellow miscellaneous copper after crushing to remove free iron, non-metallic inclusions, ash, etc., fully mix, take a representative sample of 10-20 kg and add it to a crucible, induction heating and melting, heat preservation, slag removal, and chemical Ingredient sample, analyze the composition, ready for use;

[0052] b) Recycled copper raw materials, brass processing scraps, aluminum-containing copper alloy scrap, recycled aluminum scrap, zinc-nickel-nickel scrap, nickel-plated copper scrap, nickel-plated brass scrap, tin bronze scrap, tin-plated copper scrap, plating Tin waste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com