A carbon cloth loaded cote/coo/co nanosheet array electrode material and its application

A nanosheet array and electrode material technology, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., can solve the problems of difficult preparation of arrays, and achieve the effect of wide source of raw materials, large contact area and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

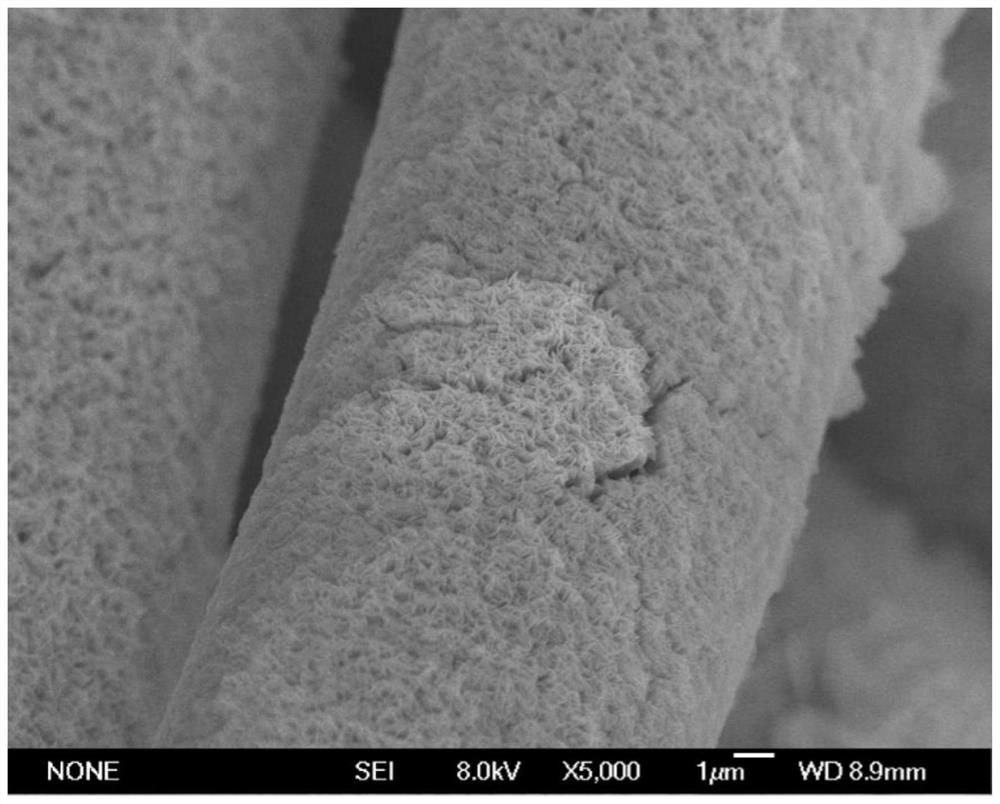

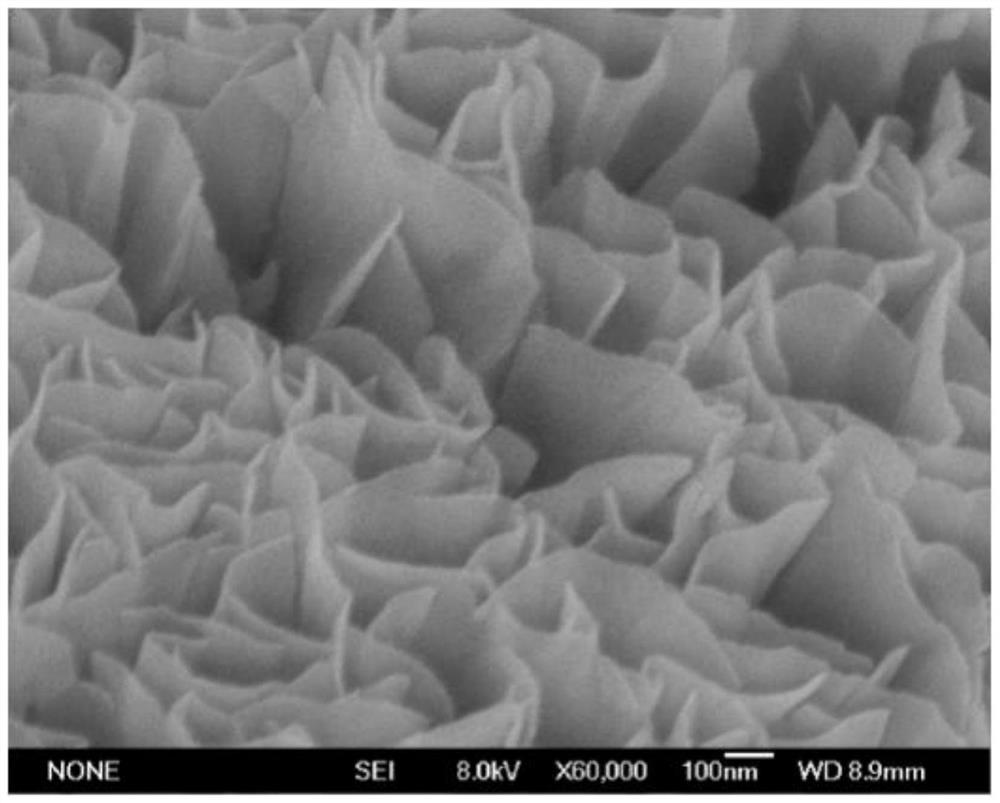

Embodiment 1

[0040] 1. Cut the carbon cloth into regular-sized rectangles, then wash the carbon cloth three times with ethanol, then three times with deionized water, and set aside;

[0041] 2. Add Co(NO 3 ) 2 ·6H 2 O was added to deionized water to prepare 0.1M Co(NO 3 ) 2 ·6H 2 O solution;

[0042] 3. Using cyclic voltammetry to convert Co(OH) 2Deposit on carbon cloth, use carbon cloth as electrodeposition substrate and working electrode, Ag / AgCl as working electrode, Pt wire as counter electrode, Co(NO 3 ) 2 The solution is electrolyte, the voltage window is -0.8V~-1.2V, at 20mV s -1 The scanning rate cycle is 30 segments. After the electrodeposition is completed, take out the carbon cloth and wash it with deionized water for three times, then with ethanol for three times, and then dry it for later use;

[0043] 4. Weigh 77mg Te powder and disperse it in 50mL deionized water, add 110mg NaBH quickly under magnetic stirring 4 powder, continue to stir for 2 minutes to obtain a bl...

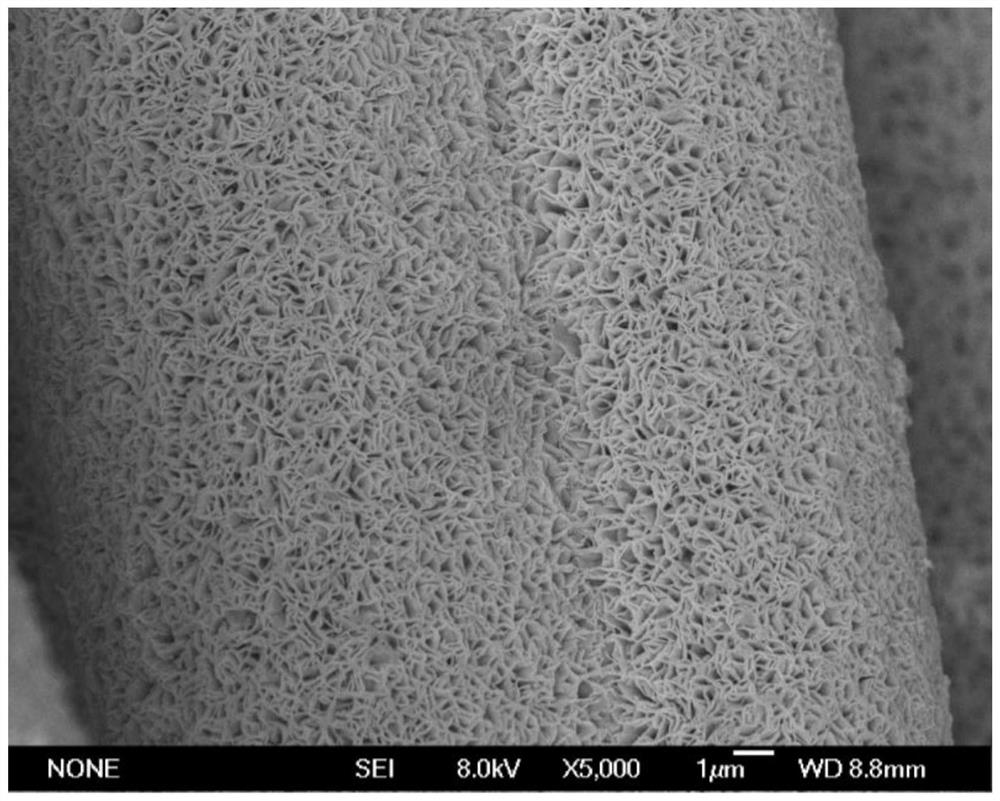

Embodiment 2

[0057] 1. Cut the carbon cloth into regular-sized rectangles, then wash the carbon cloth three times with ethanol, then three times with deionized water, and set aside;

[0058] 2. Add Co(NO 3 ) 2 ·6H 2 O was added to deionized water to prepare 0.1M Co(NO 3 ) 2 ·6H 2 O solution;

[0059] 3. Using cyclic voltammetry to convert Co(OH) 2 Deposit on carbon cloth, use carbon cloth as electrodeposition substrate and working electrode, Ag / AgCl as working electrode, Pt wire as counter electrode, Co(NO 3 ) 2 The solution is electrolyte, the voltage window is -0.8V~-1.2V, 20mV s -1 The scanning rate cycle is 30 segments. After the electrolysis is completed, take out the carbon cloth and wash it with ethanol three times, then wash it with deionized water three times, and then dry it for later use;

[0060] 4. Weigh 77mg Te powder and disperse it in 50mL deionized water, add 110mg NaBH quickly under magnetic stirring 4 powder, continue to stir for 2 minutes to obtain a black liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com