Multi-hole ultrathin palladium nanosheet catalyst and preparation method and application thereof

A palladium nano-catalyst technology, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem that the structure of multi-hole ultra-thin palladium nanosheets has not yet been realized, and achieves improved electrocatalysis of formic acid. The effect of activity and stability, high practical value, and high catalytic activity of formic acid oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Blow nitrogen into 53mL methanol for 30min to remove dissolved oxygen in methanol, then adjust the methanol to 60°C;

[0034] (2) Pass carbon monoxide to carbon monoxide saturation in above-mentioned methanol, the flow velocity of CO is 80mL / min;

[0035] (3) Add 12 mg of sodium chloropalladate to 2 mL of methanol, feed nitrogen to remove dissolved oxygen in the solution, then quickly add to the methanol saturated with carbon monoxide obtained in step (2), and continue the reaction for 5 min;

[0036] (4) The product obtained in step (3) is subjected to centrifugal cleaning.

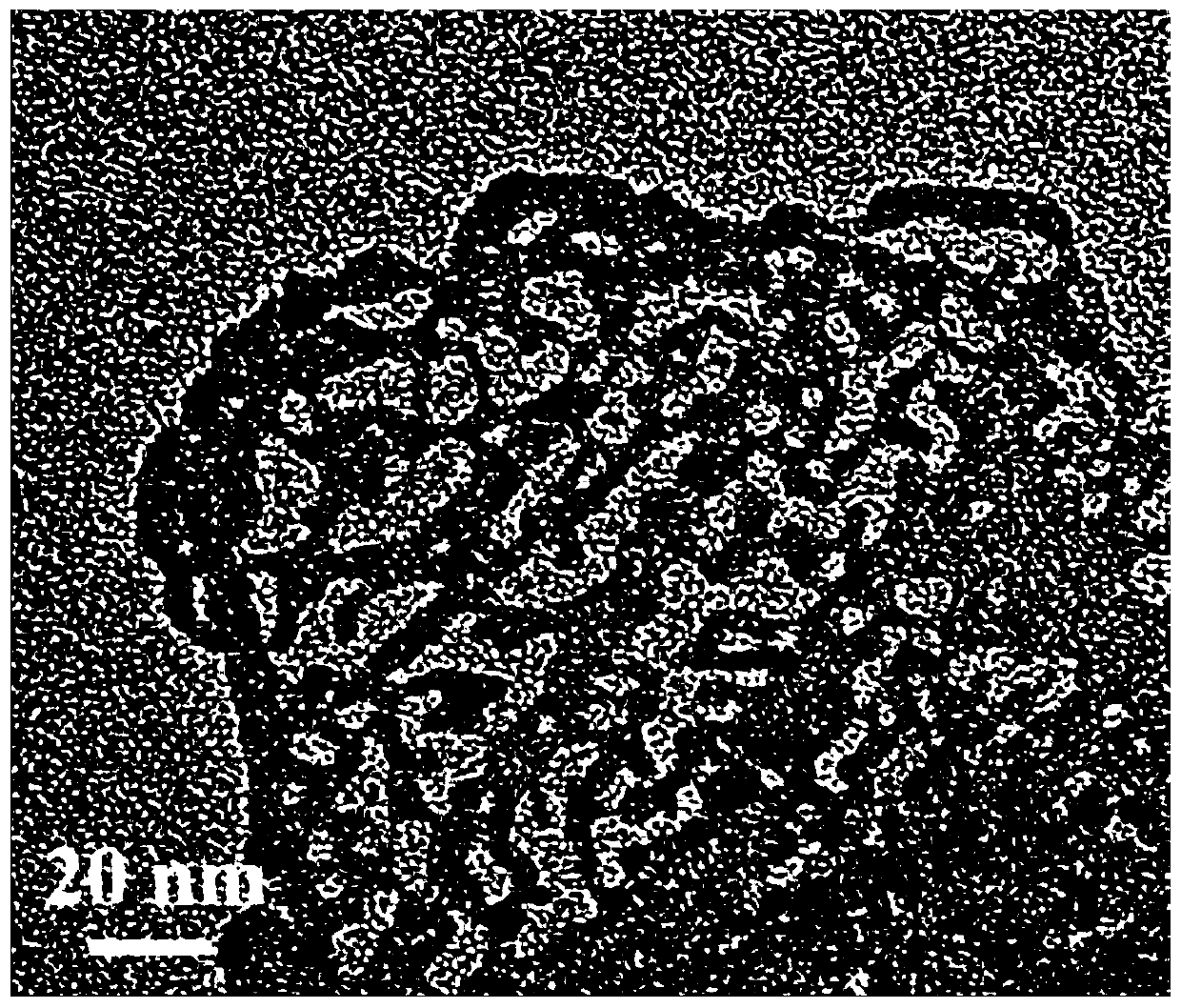

[0037] figure 1 The transmission electron microscope image of the multi-hole ultra-thin palladium nanosheet catalyst prepared in Example 1; it can be clearly seen from the figure that the prepared multi-hole ultra-thin palladium nanosheet catalyst has an obvious multi-hole structure.

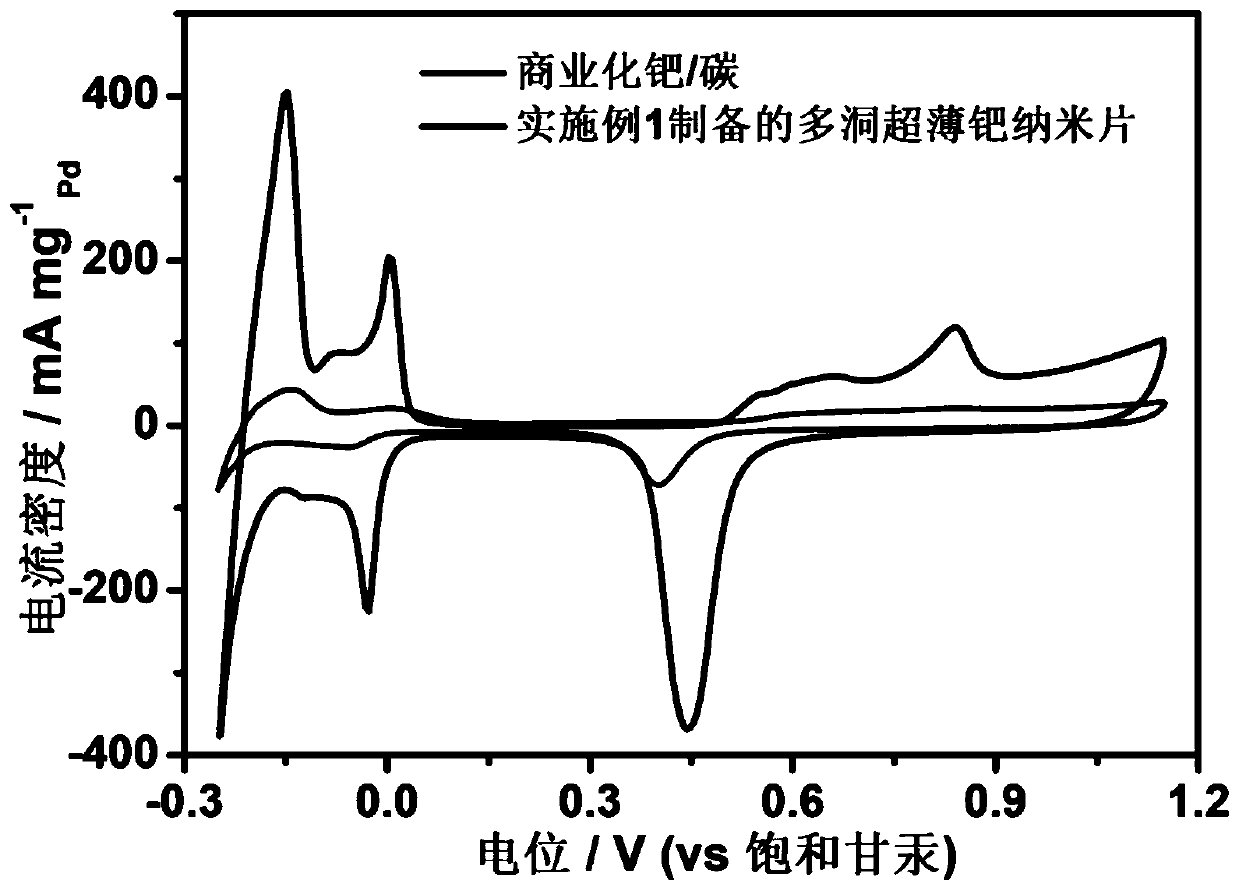

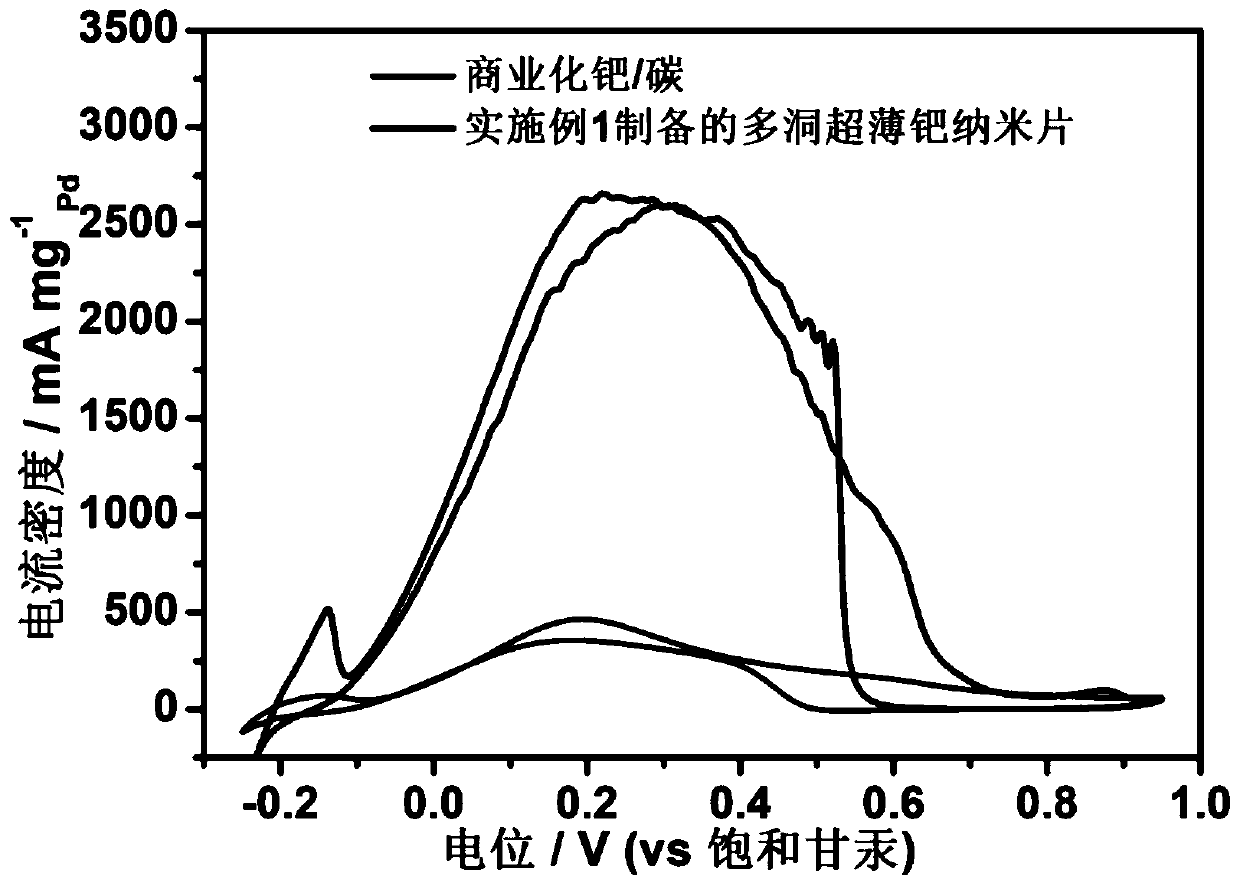

[0038] Prepare 0.5M H 2 SO 4 The solution was used as an electrolyte solution, and nitrogen gas was passe...

Embodiment 2

[0044] (1) Blow nitrogen into 48mL methanol for 30min to remove dissolved oxygen in methanol, then adjust the methanol to 40°C;

[0045] (2) Pass carbon monoxide to carbon monoxide saturation in above-mentioned methanol, the flow velocity of CO is 100mL / min;

[0046] (3) Add 5 mg of sodium chloropalladate to 2 mL of methanol, feed nitrogen to remove dissolved oxygen in the solution, then quickly add to the methanol saturated with carbon monoxide obtained in step (2), and continue the reaction for 10 min;

[0047] (4) The product obtained in step (3) is subjected to centrifugal cleaning.

[0048] Figure 5 The transmission electron microscope image of the multi-hole ultra-thin palladium nanosheet catalyst prepared in Example 2; it can be clearly seen from the figure that the prepared multi-hole ultra-thin palladium nanosheet catalyst has an obvious multi-hole structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com