Mountable fibula reconstruction and jawbone defect model, and manufacturing method and application thereof

A production method and model technology, applied in the field of oral and maxillofacial-head and neck surgery, can solve the problems of immovability, inability to achieve assembly, and increase the difficulty of denture restoration, achieve accurate fitting of the opposite jaw, reduce operation time, and facilitate The effect of denture restoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

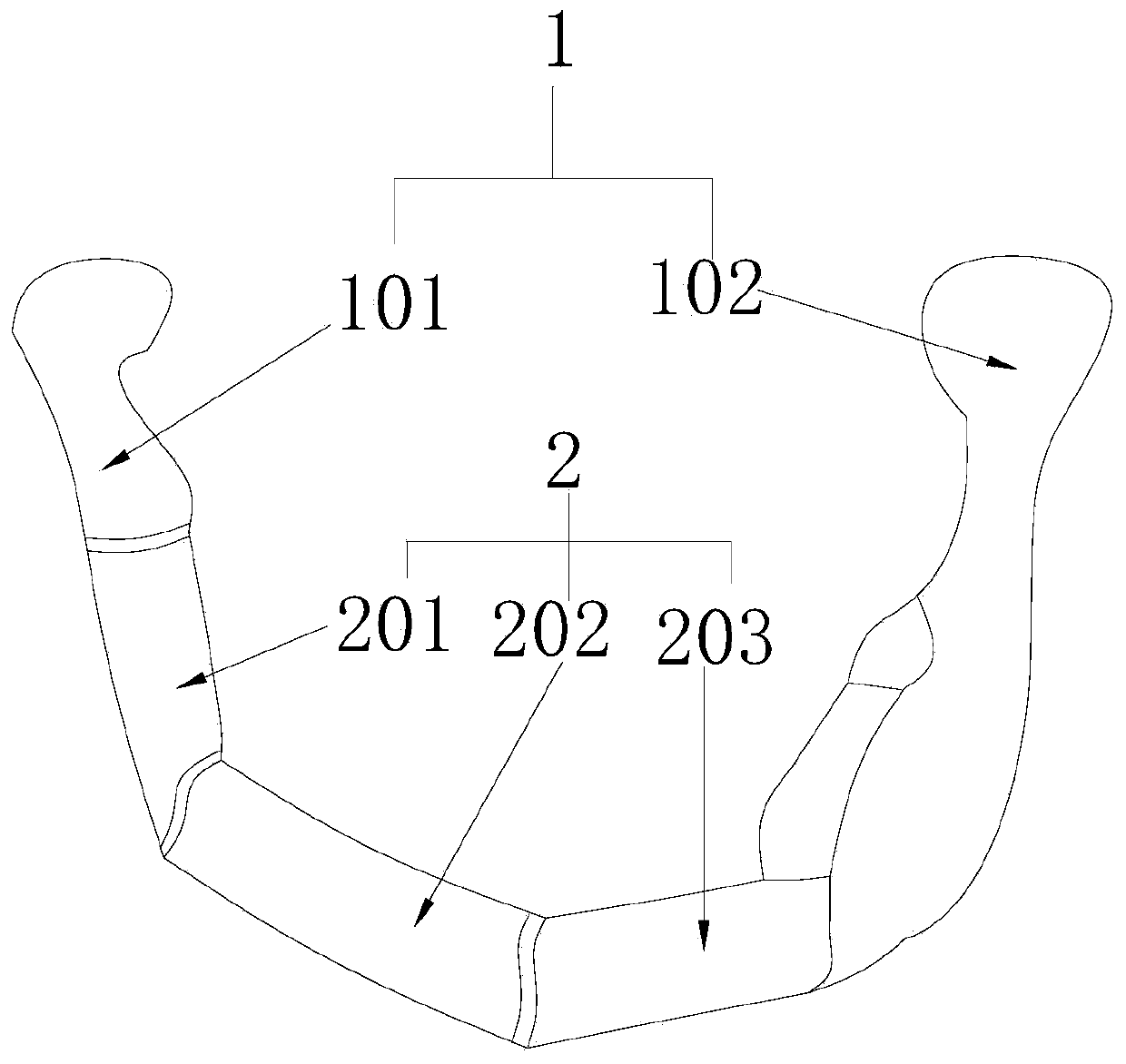

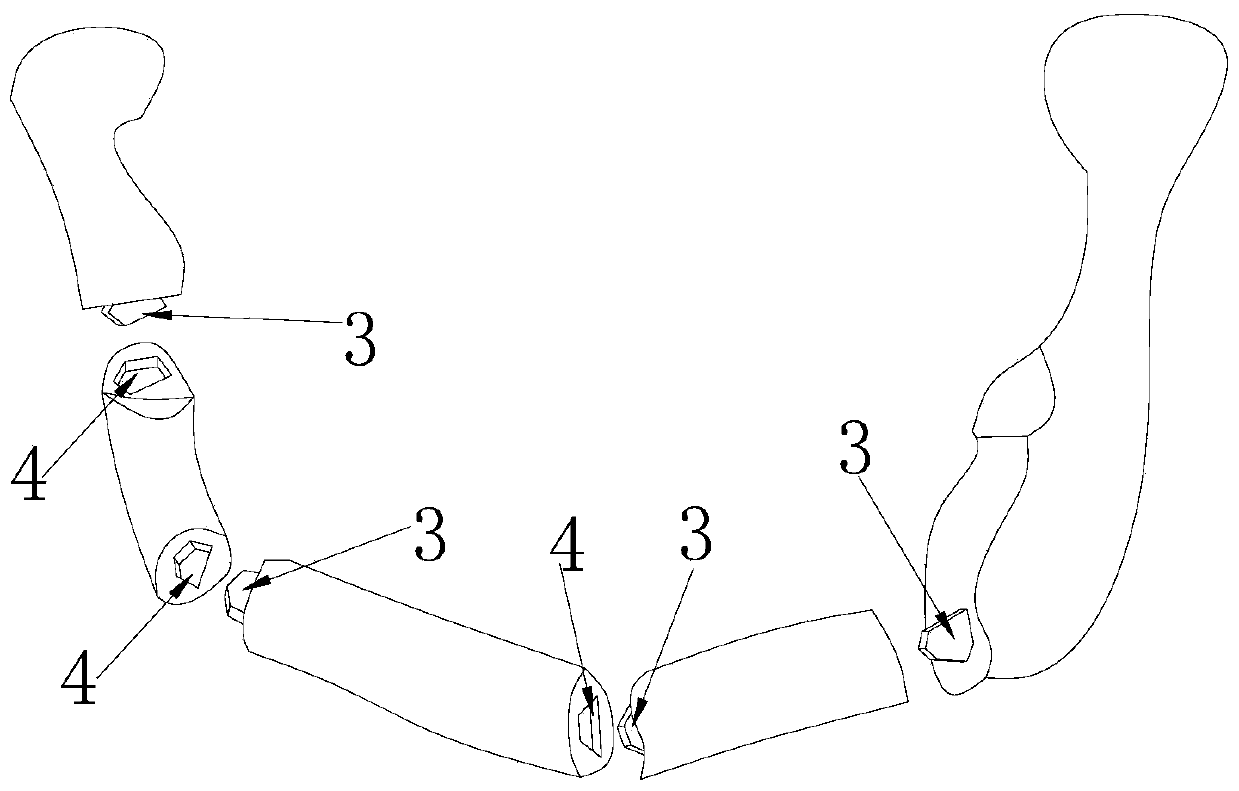

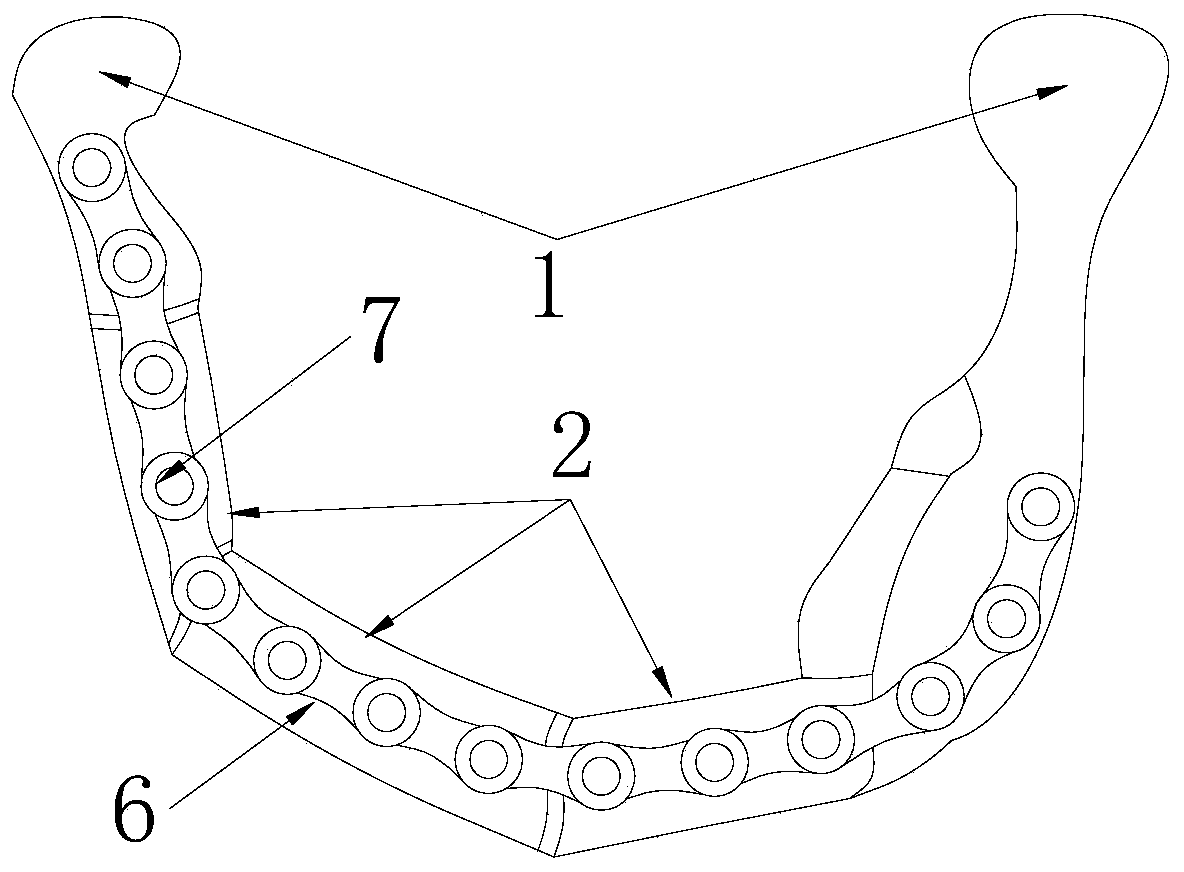

[0034] A mandibular defect model that can be assembled with fibula, please refer to the appendix figure 1 - As shown in the accompanying drawing-2, it includes a jaw defect model body 1 and a plurality of fibula model bodies 2 that can be assembled with each other, and is characterized in that, after the plurality of fibula model bodies 2 are assembled with each other, they can be combined with the jaw defect model body 1 Assembled into a complete fittable fibula reconstruction jaw model.

[0035] Further, the jaw defect model body 1 includes a first jaw defect model body 101 and a second jaw bone defect model body 102, and the plurality of interfittable fibula model bodies 2 includes a first fibula model body 201, a second Two fibula model bodies 202 and a third fibula model body 203, the first fibula model body 201, the second fibula model body 202, the third fibula model body 203, the first jaw defect model body 101 and the second jaw bone defect The model body 102 is resp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com