The preparation method of impurity-free preyssler type heteropoly acid

A heteropolyacid, impurity-free technology, applied in the direction of chemical instruments and methods, physical/chemical process catalysts, organic compounds/hydrides/coordination complex catalysts, etc., can solve the problems of reducing product purity and high content, and achieve improvement Yield and purity, simple process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

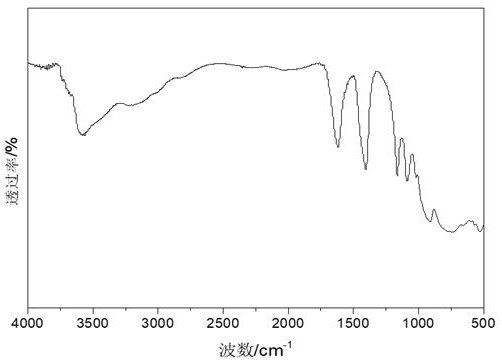

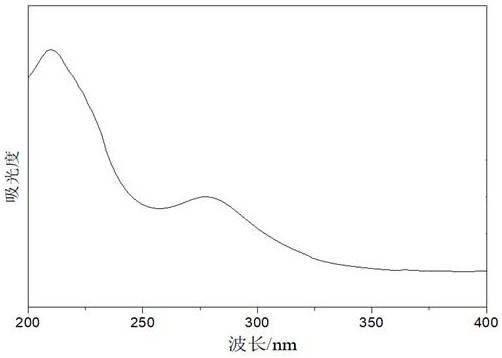

Image

Examples

Embodiment 1

[0026] The present embodiment provides the preparation method of impurity-free Preyssler-type heteropolyacid, comprising the following steps:

[0027] 1. Dissolve 30g of sodium tungstate in 30mL of deionized water, add 28.5mL of phosphoric acid solution with a mass fraction of 85% dropwise within 2 hours under stirring conditions, and then put the above mixed solution into the reactor, at 120 ℃ condition The reaction was continued for 12 h to obtain a Preyssler-type heteropolyacid solution containing impurities.

[0028] 2. The Preyssler-type heteropolyacid solution containing impurities was taken out and cooled to room temperature to obtain a pale yellow solution.

[0029] 3. Add 15 mL of water and 10 g of ammonium chloride to the light yellow solution, stir well to form a precipitate, and filter with suction to take the white solid part.

[0030] 4. Wash the white solid with anhydrous methanol. After the washing is completed, drain the methanol on the surface of the white s...

Embodiment 2

[0034] The present embodiment provides the preparation method of impurity-free Preyssler-type heteropolyacid, comprising the following steps:

[0035] 1. Dissolve 33g of sodium tungstate in 30mL of deionized water, add 30.5mL of phosphoric acid solution with a mass fraction of 85% dropwise within 4 hours under stirring conditions, and then put the above mixed solution into the reaction kettle, under the condition of 100 ℃ The reaction was continued for 18 h to obtain a Preyssler-type heteropolyacid solution containing impurities.

[0036] 2. The Preyssler-type heteropolyacid solution containing impurities was taken out and cooled to room temperature to obtain a pale yellow solution.

[0037] 3. Add 15 mL of water and 10 g of ammonium chloride to the light yellow solution, stir well to form a precipitate, and filter with suction to take the white solid part.

[0038] 4. Wash the white solid with anhydrous methanol. After the washing is completed, drain the methanol on the surf...

Embodiment 3

[0042] The present embodiment provides the preparation method of impurity-free Preyssler-type heteropolyacid, comprising the following steps:

[0043] 1. Dissolve 27g of sodium tungstate in 30mL of deionized water, add 28mL of phosphoric acid solution with a mass fraction of 85% dropwise within 2 hours under stirring conditions, and then put the above mixed solution into the reaction kettle, under the condition of 120 ℃ The reaction was carried out for 15h to obtain a Preyssler-type heteropolyacid solution containing impurities.

[0044] 2. The Preyssler-type heteropolyacid solution containing impurities was taken out and cooled to room temperature to obtain a pale yellow solution.

[0045] 3. Add 10 mL of water and 8 g of ammonium chloride to the light yellow solution, stir well to form a precipitate, and filter with suction to take the white solid part.

[0046] 4. Wash the white solid with anhydrous methanol. After the washing is completed, drain the methanol on the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com