Coal tar hydrogenation catalyst, and preparation method and application thereof

A technology of hydrogenation catalyst and coal tar, which is applied in the direction of catalyst activation/preparation, catalyst carrier, chemical instrument and method, etc., can solve the problems of limited improvement range, and achieve the effect of reducing waste water generation, improving water resistance, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Mix and co-cook with aluminum hydroxide and sodium hydroxide to form a concentration of 345gAl 2 o 3 / L solution, and then diluted with 3.5wt% NaOH aqueous solution to prepare a caustic ratio of 1.30 and a concentration of 40 gAl 2 o 3 / L of sodium metaaluminate solution for use; the preparation concentration is 50gSiO 2 / L, a water glass solution with a modulus of 2.8 for use; prepare a C9 monoalkyl ether phosphate (pKa=4.3, HLB=7) solution with a concentration of 0.2g / mL for use; use D001 with a mesh size of 60 mesh Pore strongly acidic styrene-based cation-exchange resin is prepared into a suspension with a solid content of 50 wt%.

[0067] Add 800mL deionized water into the 5000mL reactor as the bottom water, start stirring and heating, after the deionized water is heated to 70°C, add the above four materials into the reactor in parallel, and control the flow rate of sodium metaaluminate to 15mL / min, the flow velocity of water glass is 13mL / min, the flow velo...

Embodiment 2

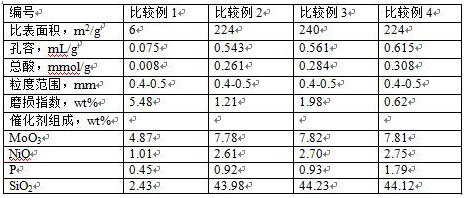

[0072] Other conditions are the same as embodiment 1, just change the concentration of water glass into 30gSiO 2 / L, flow rate is 13.3 mL / min, 60 purpose D001 macroporous strongly acidic styrenic cation exchange resin is changed to 80 purpose D002 macroporous strong acidic styrenic cation exchange resin, and the pH value of the slurry in the reactor is changed to 8.5. The obtained slurry was aged at 250° C. for 7 hours to obtain high-silicon pseudo-boehmite a2, carrier Z-2 and catalyst C-2. The specific properties of the catalyst are shown in Table 1.

Embodiment 3

[0074] Other conditions are the same as in Example 1, except that C9 monoalkyl ether phosphate is changed to C9 alkyl phosphate (pKa=4.8, HLB=5), the pH value of the gel is adjusted to 9.0, and the drying condition is changed to 150°C for 6 hours , to obtain high silicon pseudo-boehmite a3.

[0075] Take 1000g of the manufactured a3 pseudo-boehmite raw material, add 7.3g of carbon black and 32.47g of rhodium nitrate, and then shape it into a ball, and roast the balled sample at 800°C for 3 hours to obtain a carrier Z3 with a particle size of 0.3-0.7mm. The properties are shown in Table 1.

[0076] Weigh 51.61g of phosphoric acid, add 900mL of distilled water, then add 140.18g of molybdenum oxide and 64.25g of basic nickel carbonate in sequence, heat and stir until completely dissolved, then dilute the solution to 1000mL with distilled water to obtain solution L2.

[0077] Carrier Z3 was saturated and impregnated with solution L2, dried at 110°C for 4 hours, and calcined at 55...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com