Magnetic carbon-coated iron carbide nano material as well as preparation method and application thereof

A technology of carbon-coated iron carbide and nanomaterials, which is applied in the fields of magnetic materials, carbon preparation/purification, chemical instruments and methods, etc., and can solve problems such as high cost and long process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0043] A preparation method of magnetic carbon-coated iron carbide nanomaterials, comprising the following steps:

[0044] a) heating the iron source, the polycarboxy complex and the alkali source in water to obtain an intermediate product;

[0045] b) drying the intermediate product to obtain a complex precursor, and then roasting the complex precursor at 550° C. to 800° C. in an inert atmosphere to obtain a magnetic carbon-coated iron carbide nanomaterial;

[0046] Wherein, the iron source is selected from one or more of magnetite, ferrous oxide, ferric oxide and reduced iron powder, more preferably magnetite and / or ferric oxide;

[0047] The molar ratio of the iron element in the iron source to the carboxyl group in the polycarboxylate complex is 1:3-1:10, more preferably 1:4-1:5.

[0048] In the embodiment of the present invention, the alkali source can be used as a catalyst to promote the dissolution of the iron source in water. First, the polycarboxy complex reacts with...

Embodiment 1

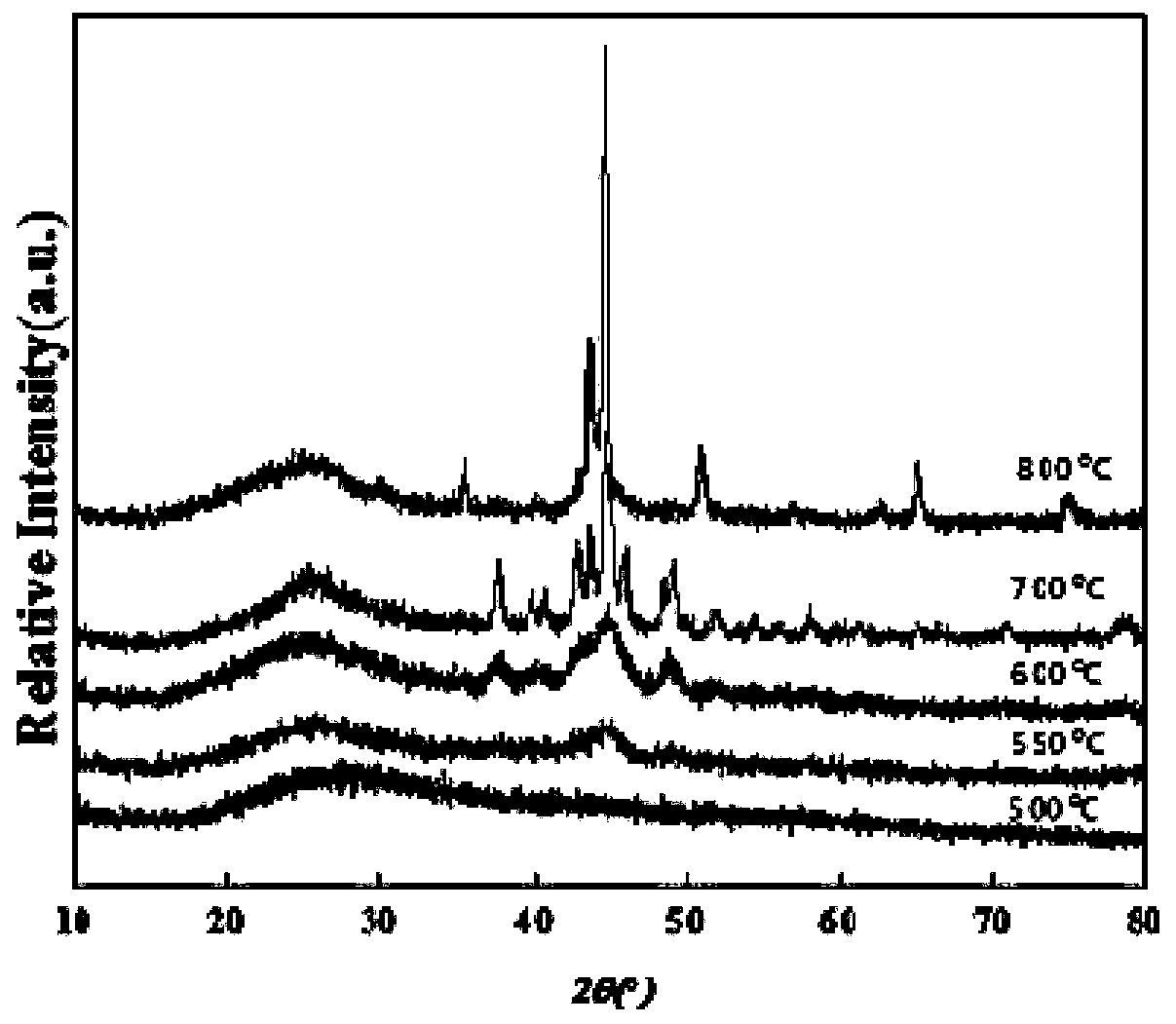

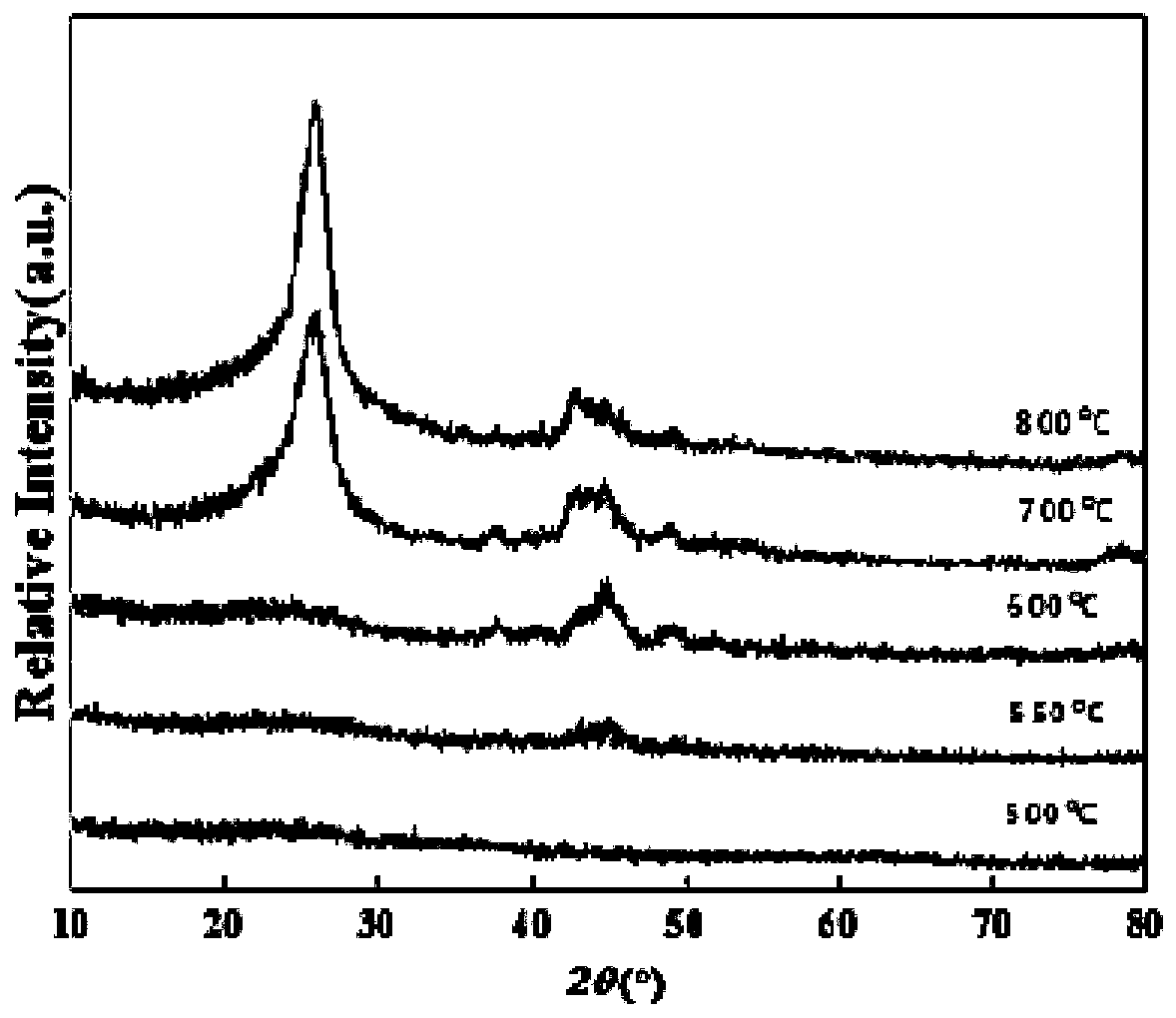

[0077] In this embodiment, different calcination temperatures are used to prepare magnetic carbon-coated iron carbide nanomaterials, specifically including:

[0078] Weigh 1.836g magnetite and 15g citric acid (C 6 h 8 o 7 ) placed in 50ml deionized water, adding concentrated ammonia water to adjust the pH value to 2, heating and reacting at 100°C until the iron source is completely dissolved (67% to 83% of the magnetite mass), then filtering, and collecting the filtrate to obtain an intermediate product.

[0079] Dry the intermediate product at 60°C for 120 hours to obtain a brown-black fluffy complex precursor, and then roast the complex precursor at 500°C, 550°C, 600°C, 700°C and 800°C in a nitrogen atmosphere For 12 hours, the heating rate before calcination was 1° C. / min, and a magnetic carbon-coated iron carbide nanomaterial was obtained.

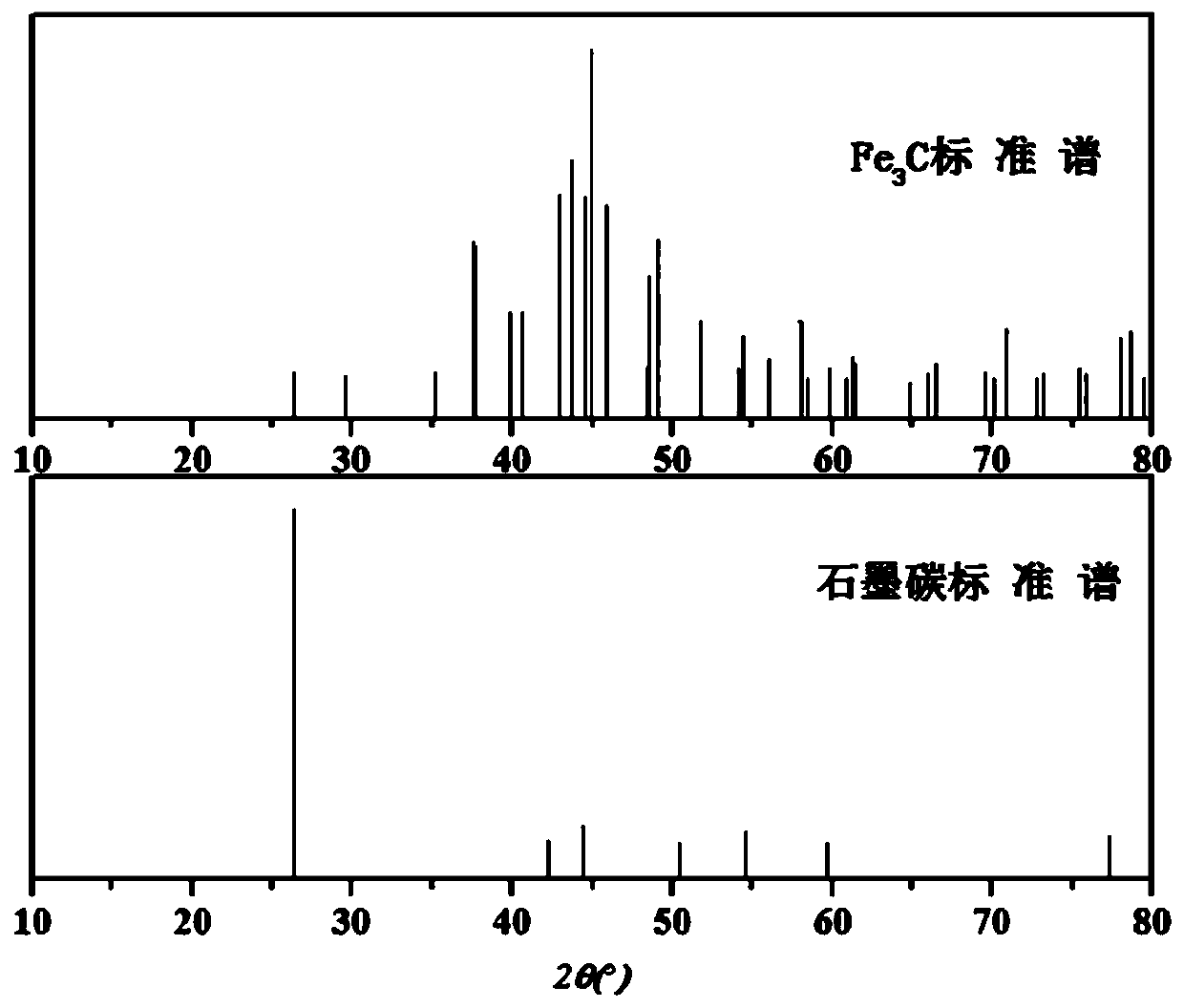

[0080] The magnetic carbon-coated iron carbide nanomaterial prepared in this embodiment is subjected to XRD analysis, and the resu...

Embodiment 2

[0084] In this embodiment, magnetic carbon-coated iron carbide nanomaterials are prepared, and the molar ratios of iron element and citric acid in magnetite are different, specifically including:

[0085]Weigh 0.918g of magnetite and 5.00g of citric acid and 0.918g of magnetite according to the molar ratio of iron element and citric acid in magnetite being 1:2, 1:3, 1:4, 1:5, 1:8 respectively. g and 7.50g citric acid, magnetite 0.918g and 10.00g citric acid, magnetite 0.918g and 12.50g citric acid, and magnetite 0.918g and 20g citric acid, respectively placed in 50ml deionized water, adding hydroxide Adjust the pH value to 5 with sodium, heat the reaction at 40°C until the iron source is completely dissolved (67%-83% of the magnetite mass), then filter, and collect the filtrate to obtain an intermediate product.

[0086] The intermediate product was dried at 170°C for 12 hours to obtain a brown-black fluffy complex precursor, and then the complex precursor was roasted at 700°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Saturation magnetization | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com