Flocculus processing equipment and method and processed flocculus

A technology for processing equipment and flakes, applied in flake processing equipment and processing fields, can solve problems such as restrictions, and achieve the effects of small restrictions, good bulkiness, and uniform spraying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

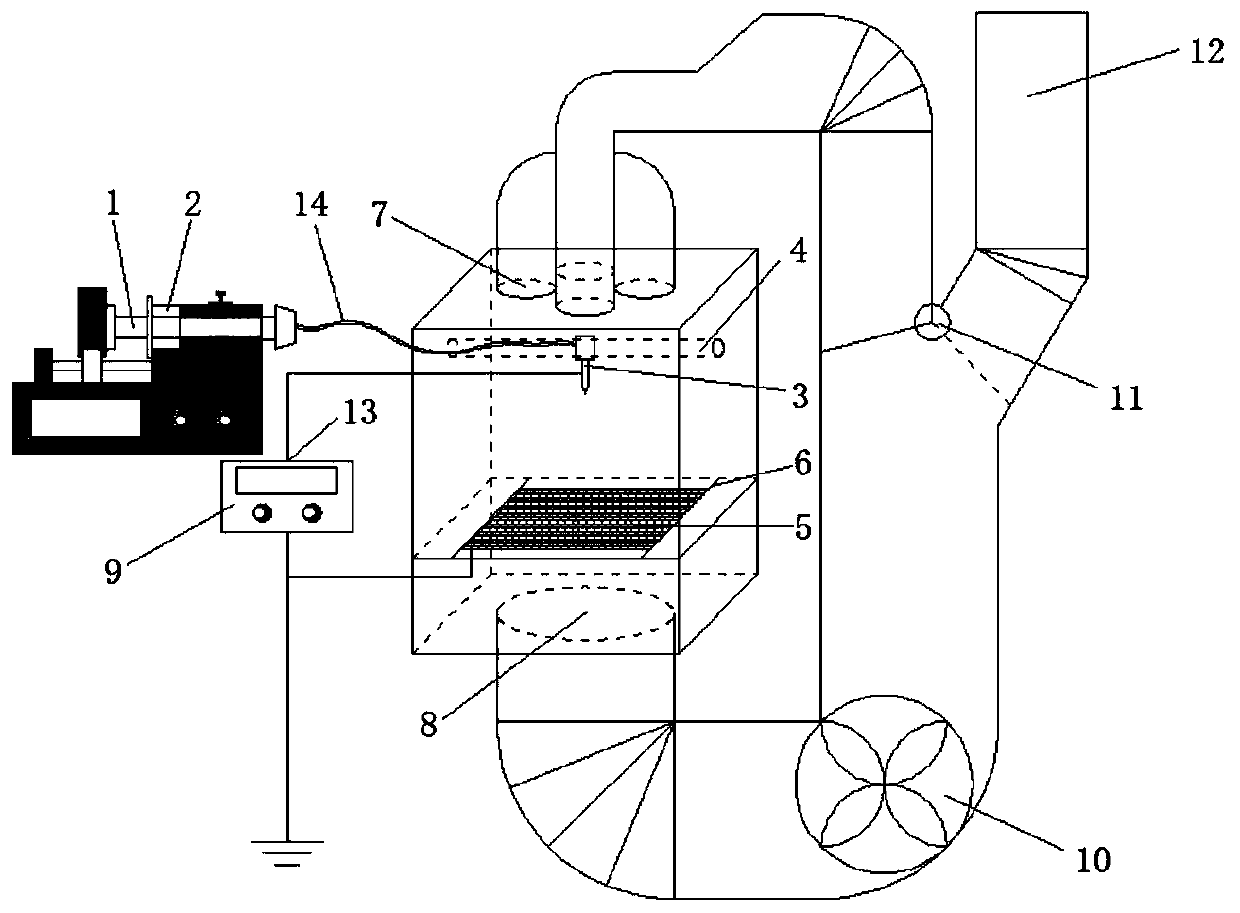

Image

Examples

Embodiment 1

[0036] The raw material is modified cotton, the dry basis content of the adhesive in the finished product is 18%, the viscosity of the adhesive is 153.3cP, the voltage applied by the high voltage generator is 13kV, the voltage connected to the conductive metal mesh is 70V, and the wind pressure of the negative pressure ventilation is 1.2Pa , adopt the alternate method of laying sheets and applying adhesive, and the ventilation time is 10s to 30s, and increases step by step with the thickness of flocs and the number of layers laid. For follow-up detection, the unit mass of the prepared flakes is 167.4g / m 2 .

[0037] The measured compression rate is 46.6%, and the recovery rate is 73.0%, which meets the first-class product standard of the national standard.

Embodiment 2

[0039] The mass ratio of spray-bonded cotton raw materials, natural cotton fiber: polyester fiber = 1:0.3 under absolute dry conditions, the dry basis content of the adhesive in the finished product is 14.8%, the viscosity of the adhesive is 134.3cP, and the voltage applied by the high voltage generator is -10kV , the conductive metal mesh is grounded, the wind pressure of the negative pressure ventilation is 1.5Pa, the method of laying the sheet to the target thickness first, and then drying with the adhesive is adopted, and the ventilation time is 180s. For follow-up detection, the unit mass of the prepared flakes is 160.2g / m 2 .

[0040] The measured compression rate is 41.7%, and the recovery rate is 76.8%, which meets the first-class product standard of the national standard.

Embodiment 3

[0042] The mass ratio of spray-bonded cotton raw materials, natural cotton fiber: polyester fiber = 1:4 under absolute dry conditions, the dry basis content of the adhesive in the finished product is 10.9%, the viscosity of the adhesive is 90.4cP, and the voltage applied by the high-voltage generator is 9kV. The conductive metal mesh is connected to a slight negative pressure, and the wind pressure of the negative pressure ventilation is 1.0Pa. It adopts the alternate method of laying sheets and applying adhesives. The ventilation time is 10s to 20s. For follow-up detection, the unit mass of the prepared flakes is 150.3g / m 2 .

[0043] The measured compression rate is 40.5%, and the recovery rate is 78.8%, which meets the first-class product standard of the national standard.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com