Multistage continuous auxiliary heating energy saving device of dimethyl ether gas-fired boiler combustor and application of multistage continuous auxiliary heating energy saving device

A gas-fired boiler and energy-saving device technology, applied in the direction of non-flammable liquid/gas transportation, combustion methods, combustion equipment, etc., can solve the problems of low thermal efficiency, and achieve the effects of enhanced combustion efficiency, clean energy, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

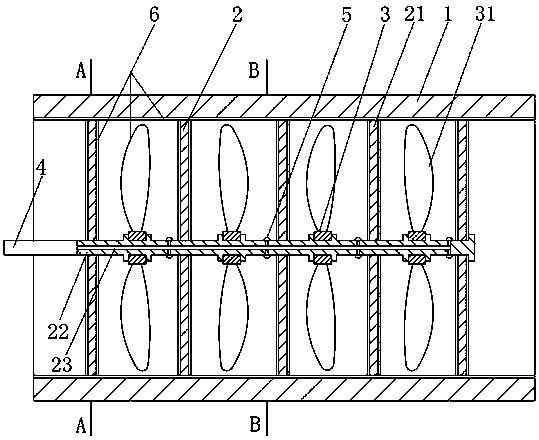

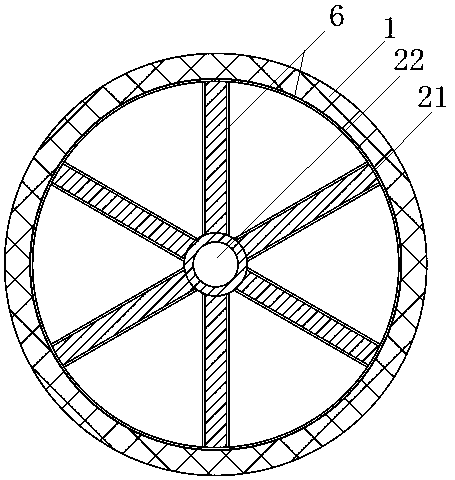

[0018] Embodiment 1, a multi-stage continuous auxiliary heat energy-saving device for a dimethyl ether gas-fired boiler burner, such as figure 1 As shown, including the auxiliary heat cylinder 1, the auxiliary heat cylinder 1 is docked with the flame injection tube of the burner, the flame of the flame injection tube will protrude along the auxiliary heat cylinder 1, then the inner wall of the auxiliary heat cylinder 1 will be completely covered by the flame, and the auxiliary heat cylinder 1 will be completely covered by the flame. The flame in the heat cylinder 1 will gradually heat the auxiliary heat cylinder 1 to a high temperature of 800 degrees Celsius.

[0019] A bracket 2 is arranged inside the auxiliary heat cylinder 1 , and a rotating impeller 3 is connected to the bracket 2 , and the blades 31 of the rotating impeller 3 are arranged obliquely relative to the central axis of the auxiliary heat cylinder 1 . The rotating impeller 3 can not only block the flame and make...

Embodiment 2

[0023] Example 2, multi-stage continuous auxiliary heat energy-saving device for dimethyl ether gas boiler burner, the water supply pump is connected to a controller, and a solenoid valve connected to the controller is provided between the pump water port of the water supply pump and the high temperature resistant pipe 4 , the solenoid valve is connected to a controller through a timer, and the controller is connected to a temperature sensor for monitoring the temperature of the auxiliary heat cylinder 1 . The controller controls the working state of the solenoid valve according to the real-time temperature detected by the temperature sensor, and then controls the working state of the high-temperature-resistant atomizing nozzle 5 in real time.

[0024] Only when the temperature reaches 800 degrees Celsius and the timer reaches the opening time of the solenoid valve, the controller controls the solenoid valve to open, and the high temperature resistant atomizing nozzle sprays wa...

Embodiment 3

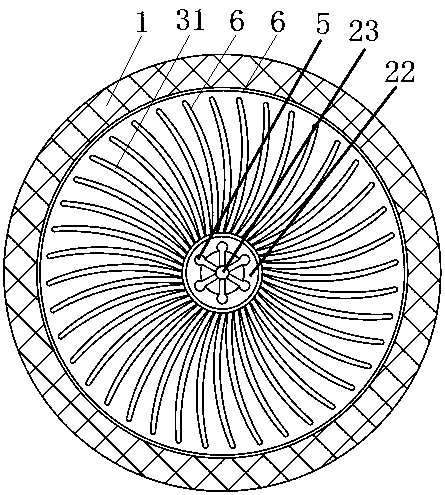

[0026] Embodiment 3, a multi-stage continuous auxiliary heat energy-saving device for a dimethyl ether gas-fired boiler burner. The high-temperature-resistant atomizing nozzles 5 are arranged at intervals in a ring along the circumference of the central rod 22, which can make the spraying of water mist more uniform and make the lanthanum oxide The amount converted to lanthanum hydroxide is more sufficient.

[0027] If the inclination angle between the blades 31 and the central axis of the auxiliary heat cylinder 1 is too large, the blades 31 will not rotate; It will not produce too much resistance to the flame, and can rotate with it.

[0028] Other structures of this embodiment are the same as Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com