Manipulator device for square bar transferring

A manipulator and square rod technology, applied in manipulators, program-controlled manipulators, grinding machine parts, etc., can solve the problems of increasing the removal allowance of silicon rods, increasing processing time, affecting processing efficiency, etc., and achieving protection from mechanical Damage, Accuracy Improvement, Wide Range of Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

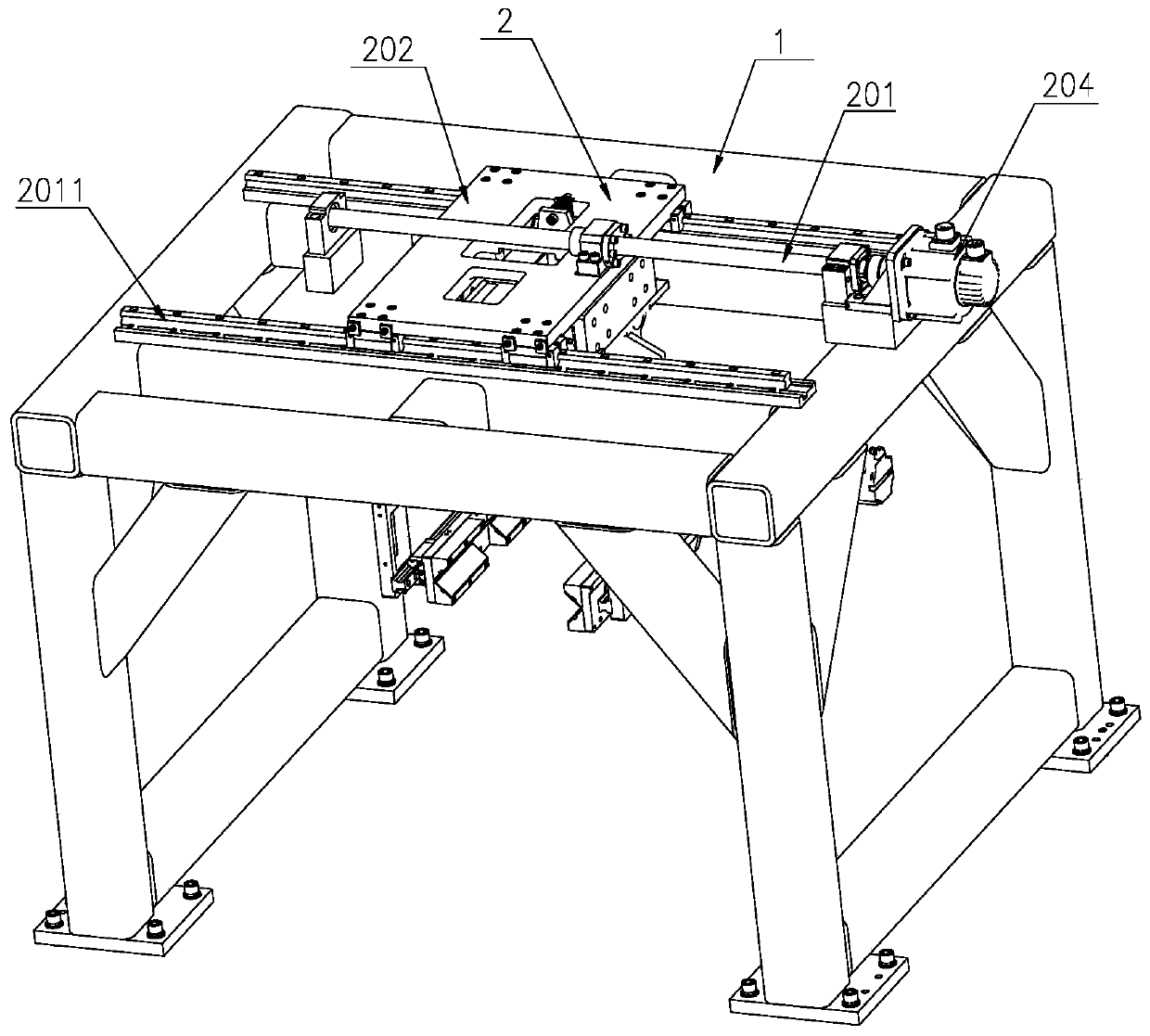

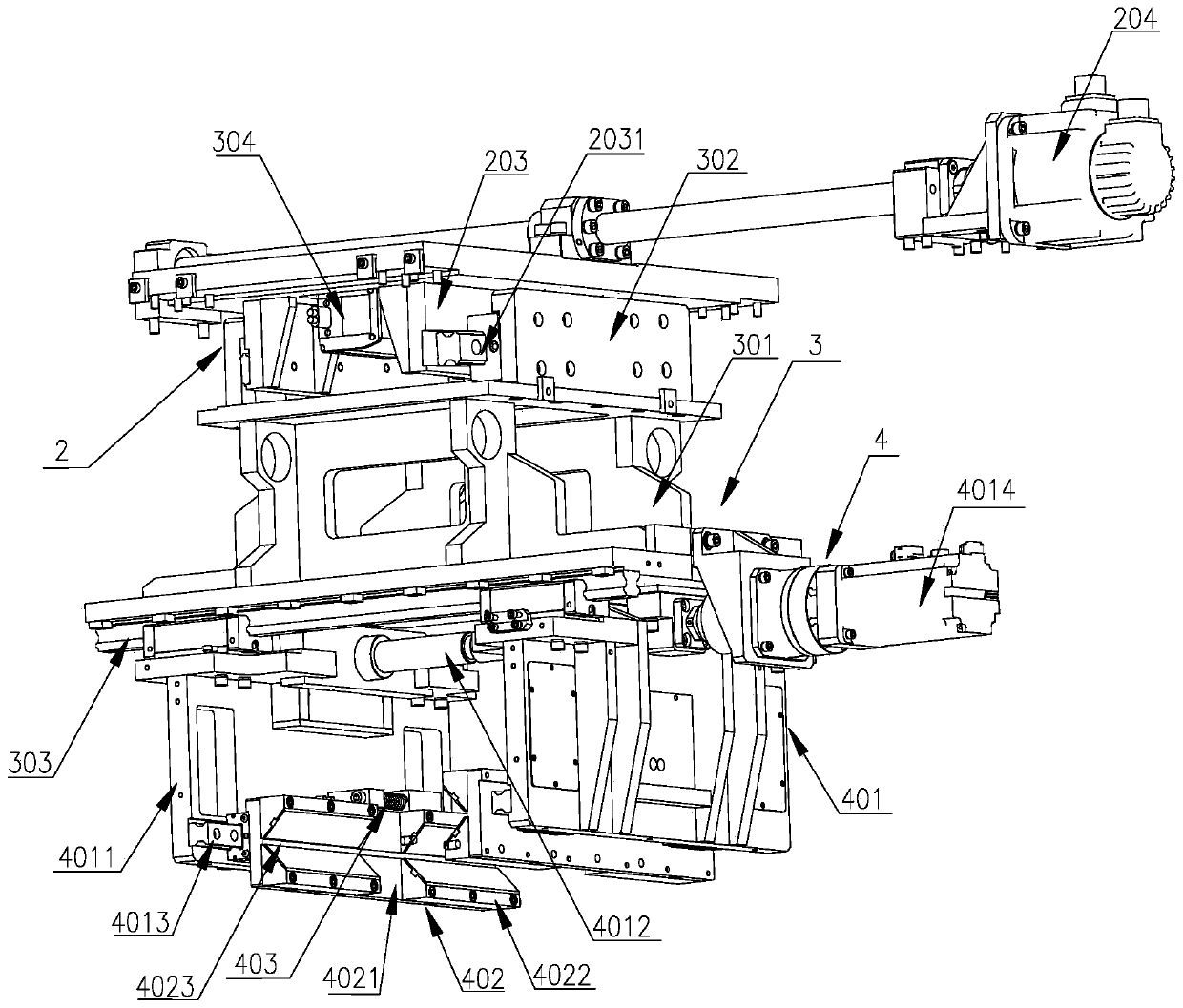

[0033] refer to figure 1 , figure 2 , the grip bracket assembly 2 includes a first lead screw 201, a grip fixing plate 202 and a relay motor 204, the first lead screw 201 is arranged along the Y-axis direction, and its two ends are fixed by the first lead screw 201 It is fixedly connected with the upper part of the transfer frame 1, and the two sides of the first lead screw 201 are respectively provided with first slide rails 2011 to cooperate with the first lead screw 201, and the two ends of the first slide rail 2011 are connected with the transfer The frame 1 is fixed, and the first sliding rail 2011 is arranged parallel to the first lead screw 201 . The handle fixing plate 202 is fixedly connected with the first lead screw 201, and is slidably connected with the transfer frame 1 through the first lead screw 201, and the output end of the transfer motor 204 is connected with one end of the first lead screw 201 to drive the first lead screw 201. Bar 201 Movement. Two sub...

Embodiment 2

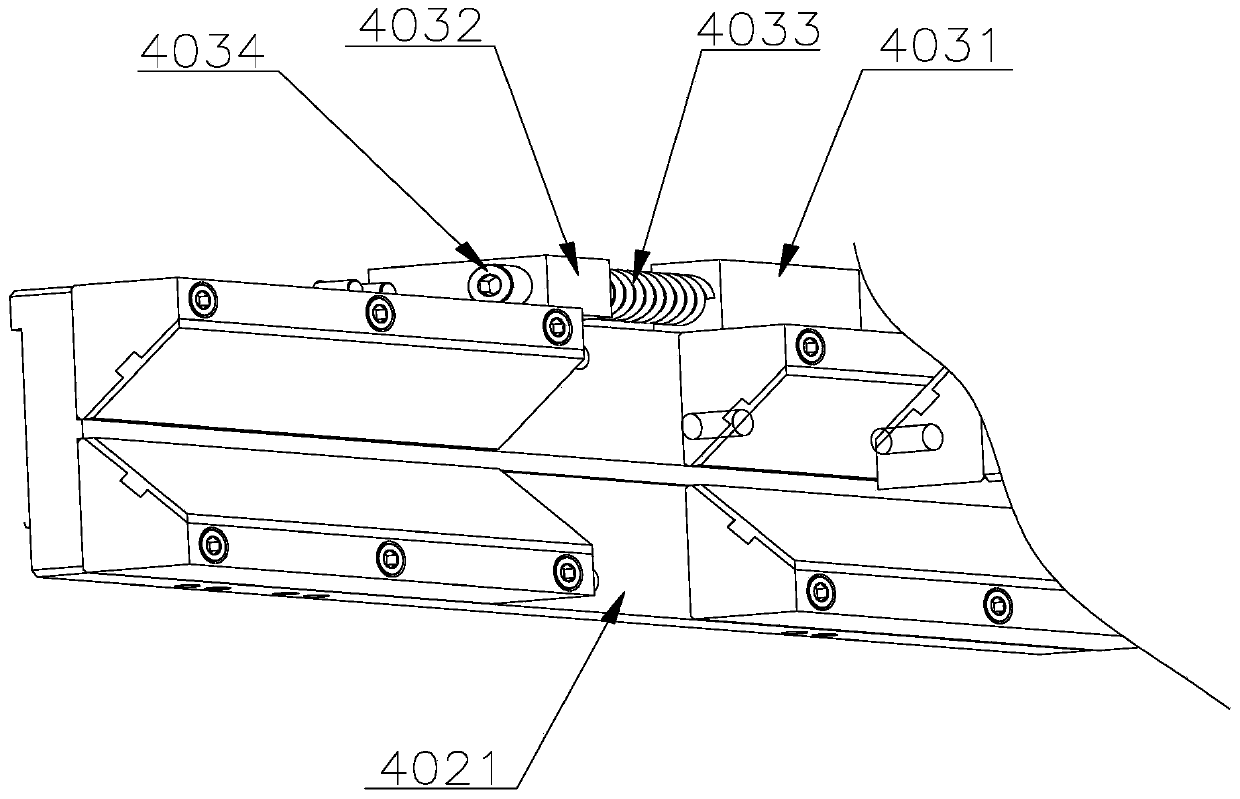

[0037] refer to figure 1 , figure 2 and image 3, the square bar clamping unit 4 includes a push plate assembly 401, a square bar fixing assembly 402 and a buffer assembly 403, the upper part of the push plate assembly 401 is slidably connected with the handle base plate assembly 3 through the third slide rail 303, and its The lower part is provided with a square bar fixing assembly 402 , and the buffer assembly 403 is installed on the push plate assembly 401 and is fixedly connected with the square bar fixing assembly 402 .

[0038] The push plate assembly 401 includes two push plates 4011 and a push plate screw 4012. The two push plates 4011 are arranged opposite to each other. In this embodiment, the push plates 4011 are located in the X and Z planes perpendicular to the Y axis. The top of the push plate 4011 is provided with a push plate groove to slide and cooperate with the third slide rail 303, and at the same time, a push plate screw 4012 is arranged between the two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com