Method for preparing musk ketone

A muscone and musk technology, applied in the separation/purification of carbonyl compounds, organic chemistry, etc., can solve the problems of poor extraction effect, high production cost, low efficiency, etc., to save consumption, save production cost, increase heating area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

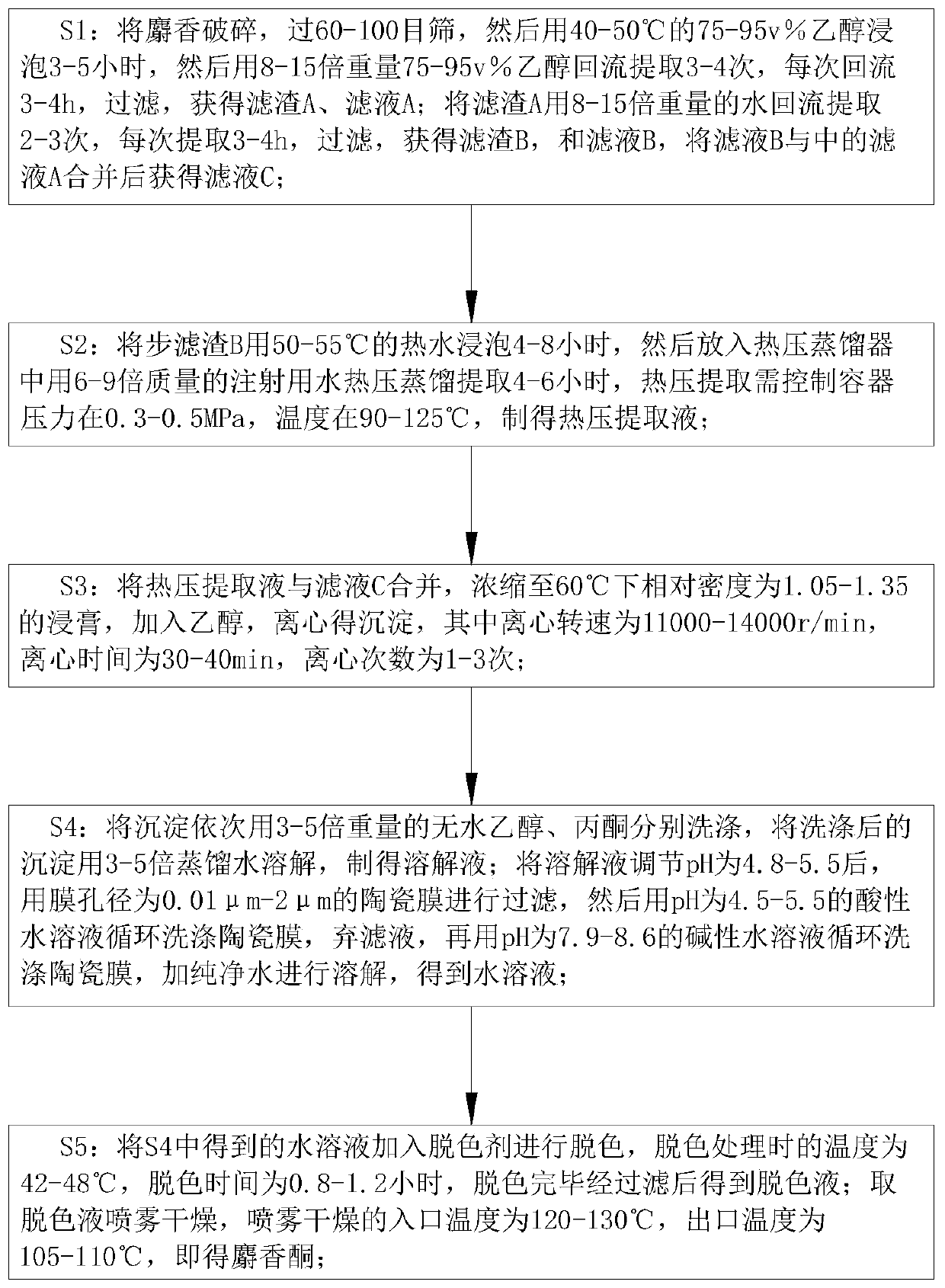

Method used

Image

Examples

Embodiment approach

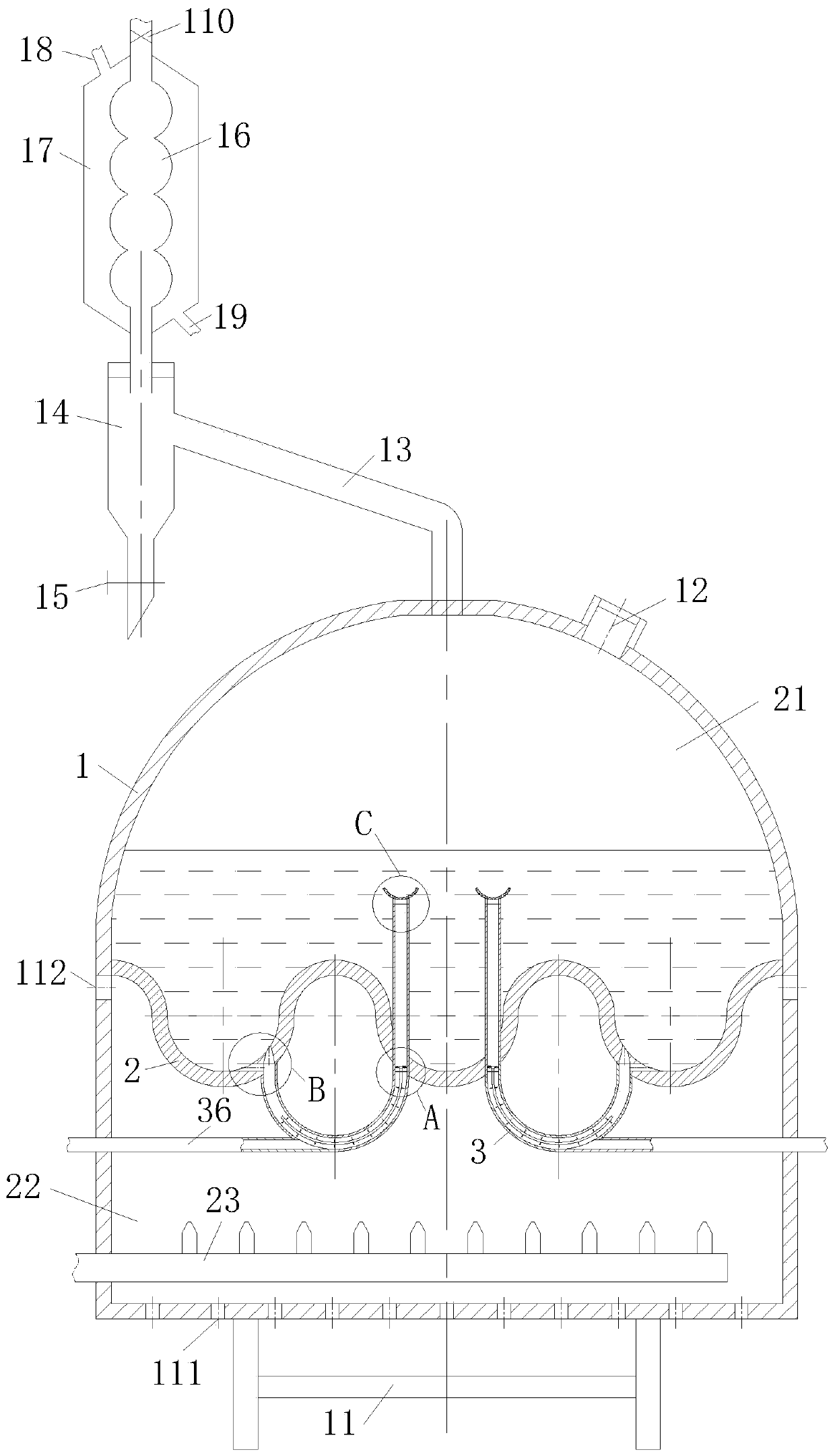

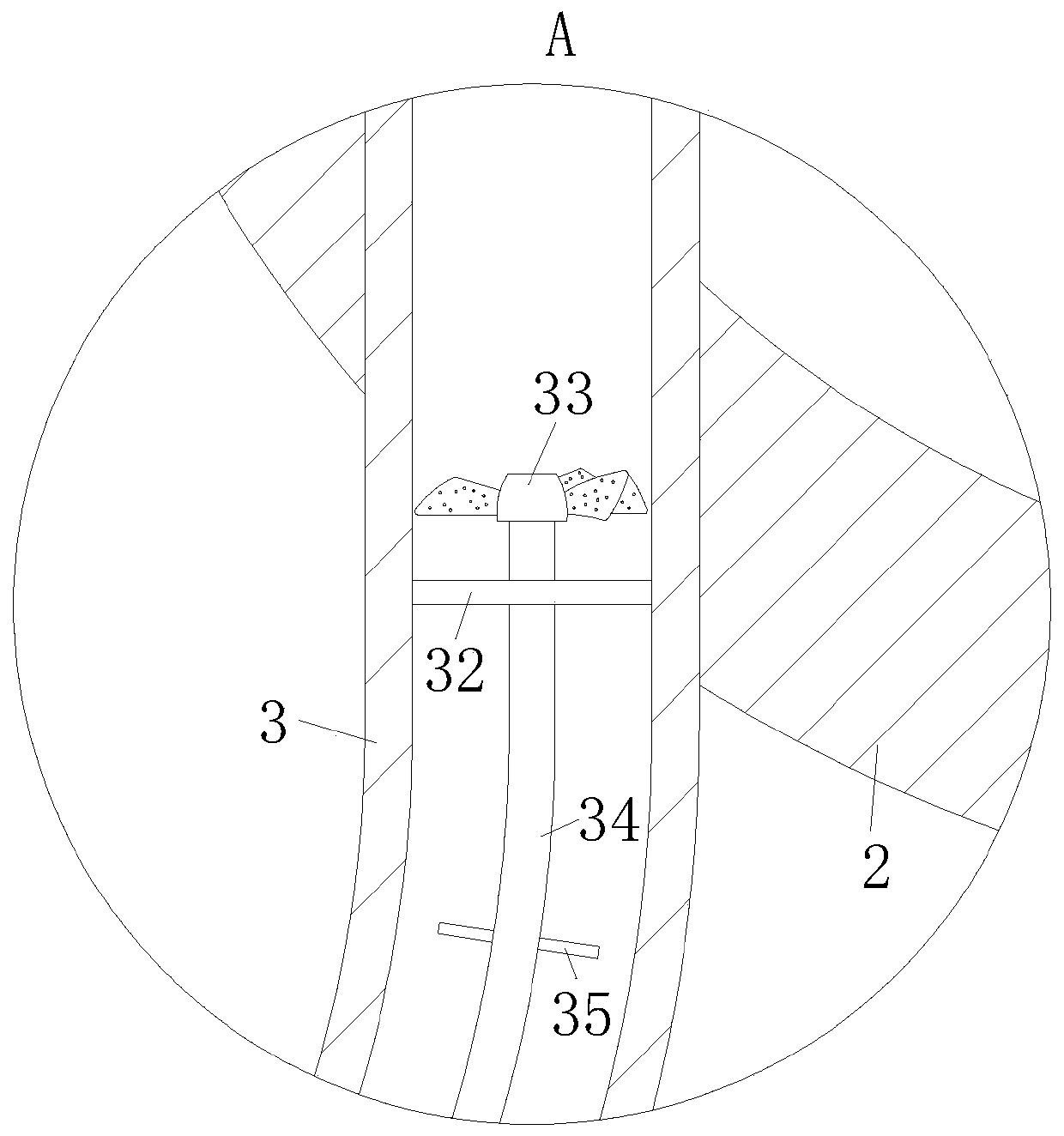

[0034] As an embodiment of the present invention, a U-shaped tube 3 is connected to the wavy bottom adjacent to the partition plate 2, and the mixed liquid in the distillation chamber 21 is rapidly heated through the U-shaped tube 3. The heating efficiency of the mixed liquid in 21 further increases the hot-pressed distillation extraction efficiency of filter residue and filtrate; the U-shaped pipe 3 extending downwards extends into the combustion chamber 22 to further increase the heating area of the mixed liquid in the distillation chamber 21 and increase the distillation chamber 21 heating efficiency, while the mixed liquid in the U-shaped tube 3 is heated and the density is reduced, and it flows upward through the thermal convection effect, so that the mixed liquid with a lower temperature in the distillation chamber 21 continuously enters the U-shaped tube 3, further increasing the distillation The heating efficiency of the chamber 21 further increases the extraction eff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com