A kind of hydrolysis-resistant cationic waterborne polyurethane adhesive and preparation method thereof

A water-based polyurethane, cationic technology, applied in the direction of polyurea/polyurethane adhesives, adhesives, adhesive types, etc., can solve the problems of ordinary water-based polyurethanes that do not meet the requirements and poor adhesion, and achieve excellent hydrolysis resistance. , improve dispersion, enhance the effect of controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

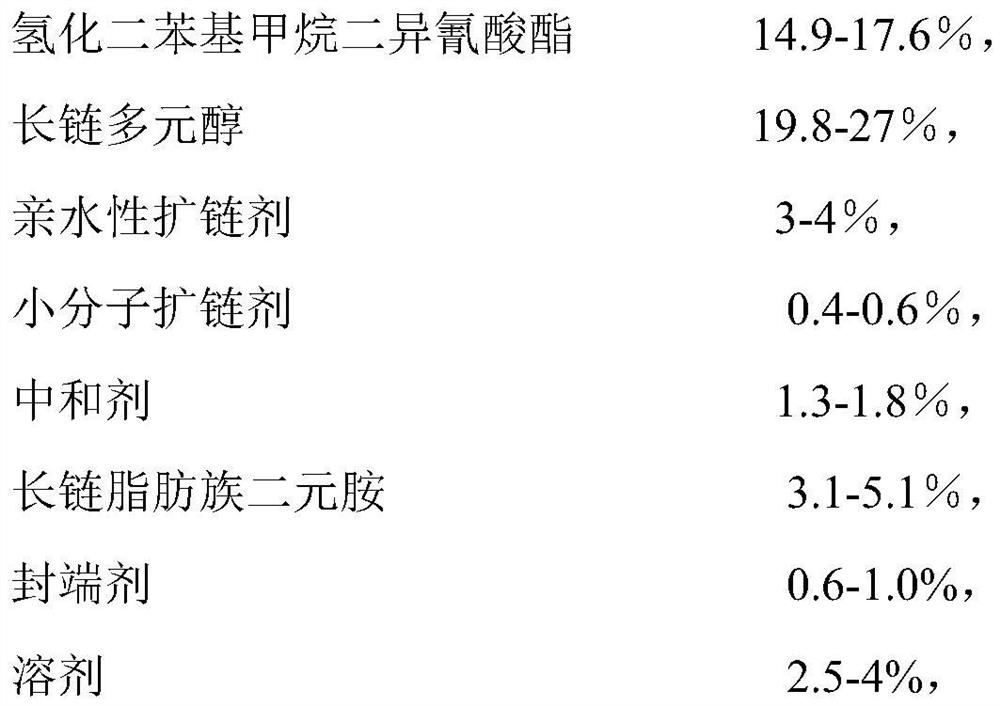

[0029] A hydrolysis-resistant cationic water-based polyurethane adhesive, consisting of the following components by mass (g):

[0030] HMDI 100 SP-2000 50 PTMG-2 100 EG 4 MDEA 19 Solvent acetone 19 acetic acid 8.6 Deionized water 320 Amino-terminated polyether 2000 33 capping agent methanol 5.8

[0031] The preparation method of described hydrolysis-resistant cationic waterborne polyurethane adhesive is as follows:

[0032] Put HMDI, SP-2000, and PTMG-2 into the reaction kettle and control the reaction temperature at 85°C. After the reaction until the NCO content reaches 10.3% of the theoretical amount, cool down to 50°C and add small molecule chain extender EG to react for 3 hours, then add MDEA to continue After reacting for 1 hour, a low-molecular-weight water-based polyurethane prepolymer was obtained. During the reaction, a solvent was added to control the viscosity to be stable. After cooling, acetic aci...

Embodiment 2

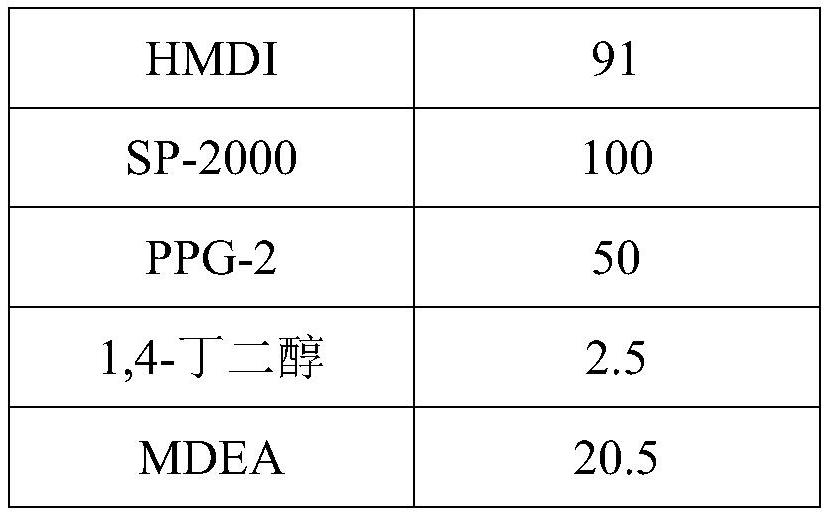

[0034] A hydrolysis-resistant cationic water-based polyurethane adhesive, consisting of the following components by mass (g):

[0035]

[0036]

[0037] The preparation method of described hydrolysis-resistant cationic waterborne polyurethane adhesive is as follows:

[0038] Put HMDI, SP-2000, and PPG-2 into the reaction kettle and control the reaction temperature at 85°C. After the reaction until the NCO content reaches 9.5% of the theoretical amount, cool down to 50°C and add small molecule chain extender 1,4-butanediol to react 3 hour, then add MDEA and continue to react for 1 hour to obtain a low molecular weight water-based polyurethane prepolymer. During the reaction, a solvent is added in good time to control the viscosity. After cooling, acetic acid is added to neutralize the pH value to 7-8, and deionized water is slowly added to the In the material system, the material is emulsified in water. After the emulsification is completed, the amino-terminated polyether...

Embodiment 3

[0040] A hydrolysis-resistant cationic water-based polyurethane adhesive, consisting of the following components by mass (g):

[0041] HMDI 120 SP-2000 80 PPG-2 80 1,3-Butanediol 3.5 MDEA 28 Solvent acetone 20 acetic acid 12.7 Deionized water 443 Polyaminopolyether 1000 34 capping agent ethanol 4.6

[0042] The preparation method of described hydrolysis-resistant cationic waterborne polyurethane adhesive is as follows:

[0043] Put HMDI, SP-2000, and PPG-2 into the reaction kettle and control the reaction temperature at 90°C. After the reaction until the NCO content reaches 11.3% of the theoretical amount, cool down to 40°C and add small molecule chain extender 1,3-butanediol to react 2 hour, then add MDEA and continue to react for 1 hour to obtain a low molecular weight water-based polyurethane prepolymer. During the reaction, a solvent is added in good time to control the viscosity. After cooling, acetic aci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com