Radial window cutting drilling device for downhole casing pipe of oil-water well

A drilling device and technology for oil and water wells, which are applied in the direction of drilling driving devices, wellbore/well components, drilling equipment, etc. in the wellbore, and can solve the problems affecting the efficiency and accuracy of radial drilling operations, casing and casing straightening Difficult segment milling, poor cementing quality and other problems, to achieve the effect of reducing labor intensity of workers, shortening drilling cycle and saving drilling cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The following is a further description of the present invention in conjunction with the accompanying drawings and embodiments.

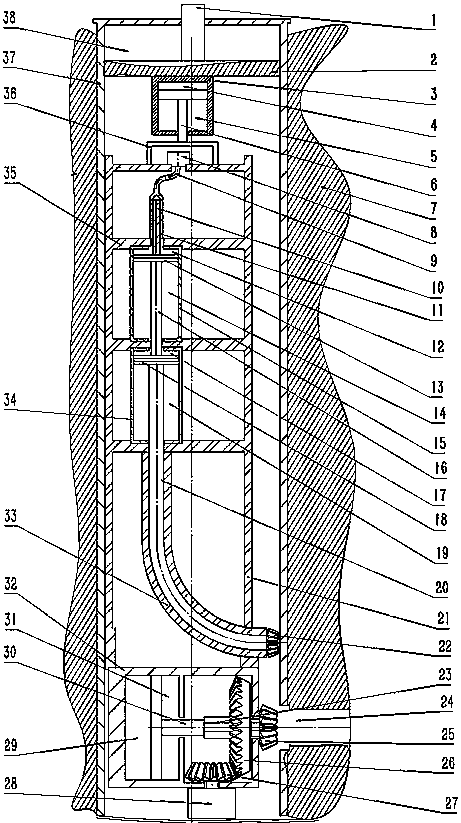

[0023] refer to figure 1 As shown, the oil-water well downhole casing radial opening drilling device includes an up and down guiding and positioning unit, a rock formation drilling unit and a radial windowing unit.

[0024] Wherein, the up and down guiding and positioning unit includes slips 2 fixed to the inner wall of the casing 37, and the bottom of the slips 2 is fixed with an up and down positioning cylinder 3 and an up and down positioning cylinder piston 6 arranged in the up and down positioning cylinder 3.

[0025] The rock formation drilling unit includes a joint 36, and the piston rod of the up and down positioning cylinder piston 6 is connected with the top of the joint 36. The lower end of the joint 36 is fixedly connected with a rock formation casing assembly, the rock formation casing assembly includes a plurality of partitions ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com