Fresh aronia melanocarpa powder with good taste and preparation method thereof

A kind of rowan powder and technology of rowan, which is applied in the direction of food ingredients as a taste improver, food shaping, and the function of food ingredients, etc., can solve the problem of bad taste, unreachable, sticky Low caking properties and other problems, to achieve the effect of benefiting the eating experience, increasing the cohesiveness, and improving the taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

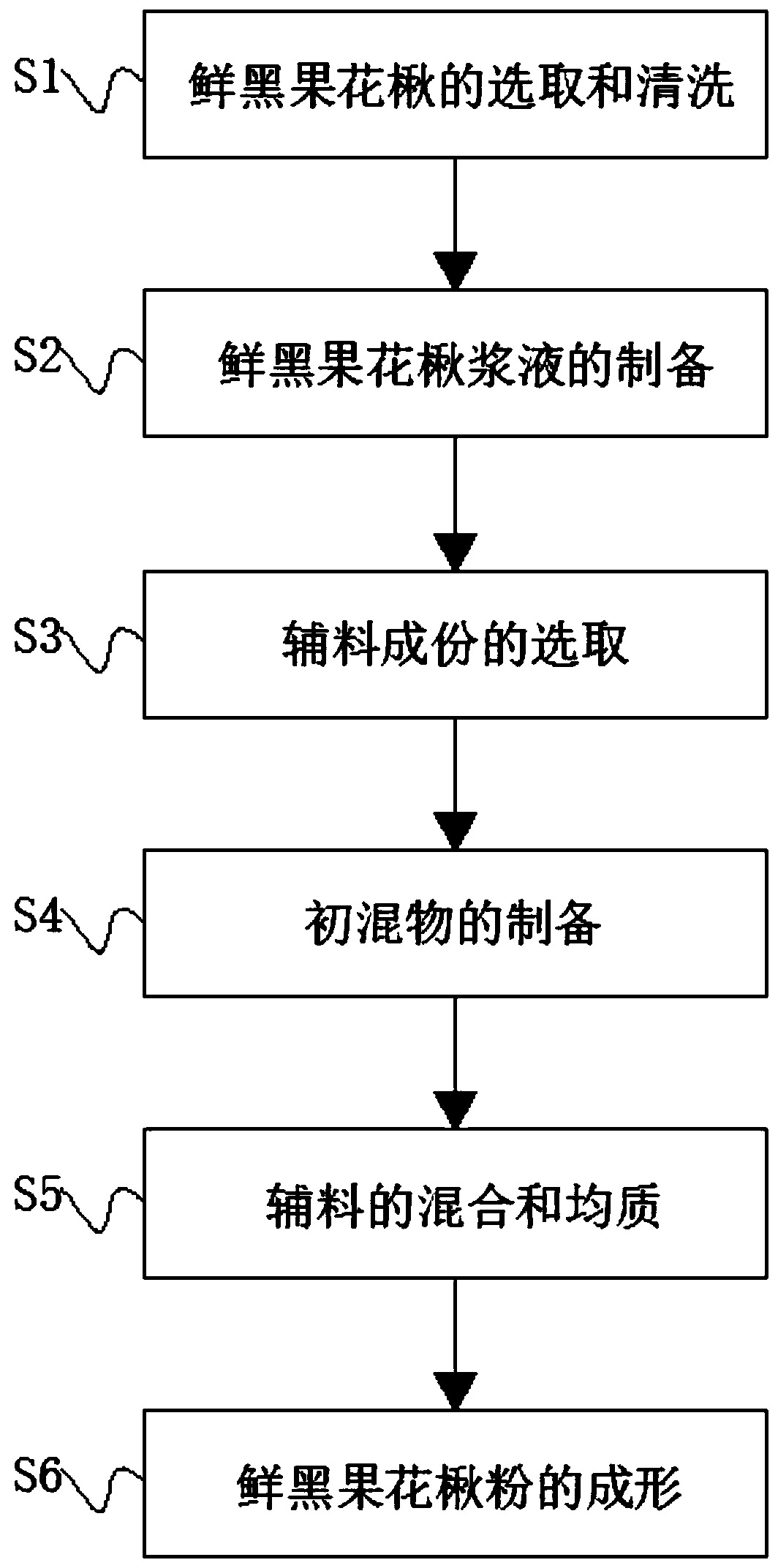

Method used

Image

Examples

Embodiment 1

[0027] S1. Selection and cleaning of fresh black fruit rowan: first select 25 parts of fresh black fruit rowan with huge fruit, fresh and free of diseases and insect pests, then pour the selected fresh black fruit rowan into the cleaning equipment, and first rinse with clean water for 3 time, and then rinsing for 2 times, so that the stains on the surface of the fresh black fruit rowan are thoroughly cleaned;

[0028] S2. Preparation of fresh Sorbus sagograss slurry: Enzyme hydrolyze the fresh Sorbus sagograss fruit after cleaning in step S1 at a temperature of 29° C. for 2 hours, and then mix the fresh Sorbus sagograss after enzymolysis with pure The water is put into the colloid mill for beating according to the ratio of 1:4, so as to obtain the fresh black fruit rowan slurry;

[0029] S3, selection of auxiliary material components: 15 parts of fruit dietary fiber extracts, 15 parts of vegetable dietary fiber extracts, 3 parts of vanillin, 3 parts of castor oil, 3 parts of t...

Embodiment 2

[0034] S1. Selection and cleaning of fresh black-fruited rowan: first select 20 parts of fresh black-fruited rowan with huge fruit and fresh and no pests and diseases, then pour the selected fresh black-fruited rowan into the cleaning equipment, and first rinse with clean water for 3 time, and then rinsing for 2 times, so that the stains on the surface of the fresh black fruit rowan are thoroughly cleaned;

[0035] S2. Preparation of fresh Sorbus sarcophagus slurry: the fresh Sorbus sago The water is put into the colloid mill for beating according to the ratio of 1:4, so as to obtain the fresh black fruit rowan slurry;

[0036] S3. Selection of auxiliary material components: 10 parts of fruit dietary fiber extract, 10 parts of vegetable dietary fiber extract, 1 part of vanillin, 1 part of castor oil, 1 part of three Glycerides, 1 part of citric acid, 0.5 part of sweetener and 0.5 part of pectin, and store the measured components through storage tanks for future use, fruit die...

Embodiment 3

[0041] S1. Selection and cleaning of fresh black fruit rowan: first select 30 parts of fresh black fruit rowan with huge fruit and fresh and no pests and diseases, then pour the selected fresh black fruit rowan into the cleaning equipment, and rinse with clean water for 4 times, and then rinse 3 times to make the stains on the surface of the fresh black fruit rowan thoroughly cleaned;

[0042] S2. Preparation of fresh Sorbus sarcophagus slurry: the fresh Sorbus sago The water is put into the colloid mill for beating according to the ratio of 1:4, so as to obtain the fresh black fruit rowan slurry;

[0043] S3, selection of auxiliary material components: 20 parts of fruit dietary fiber extract, 20 parts of vegetable dietary fiber extract, 5 parts of vanillin, 5 parts of castor oil, 5 parts of three Glycerides, 2 parts citric acid, 1 part sweetener, and 1 part pectin, and measure each component through storage jars for storage until use, fruit dietary fiber extracts are citrus,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com