Waste heat recovery steam car washer based on alcohol-based fuel

An alcohol-based fuel and waste heat recovery technology, which is applied in the field of car washing machines, can solve the problems of smoke damage to people and the environment, and achieve the effects of high heat energy utilization, pollution reduction, and good environmental protection characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

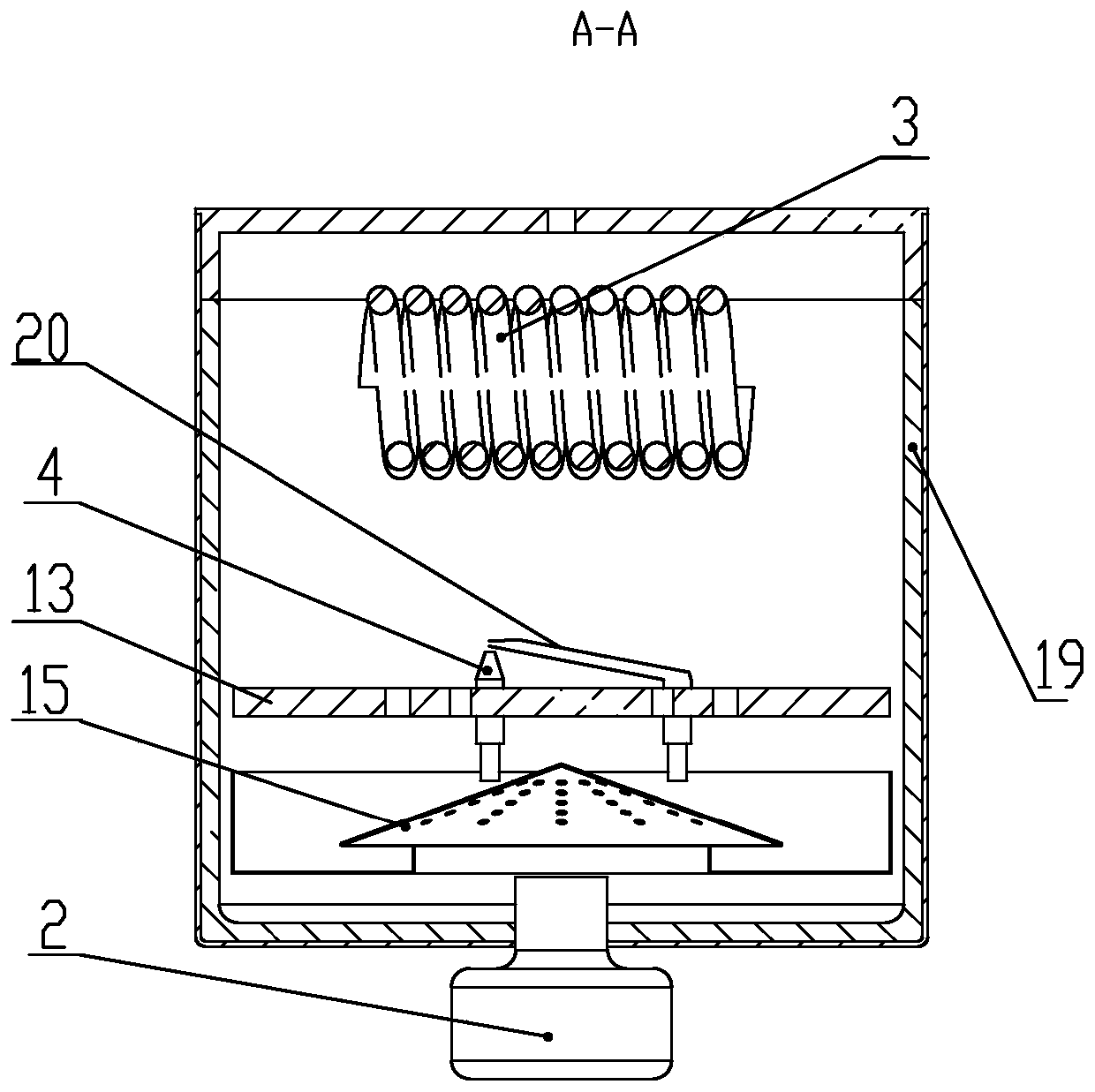

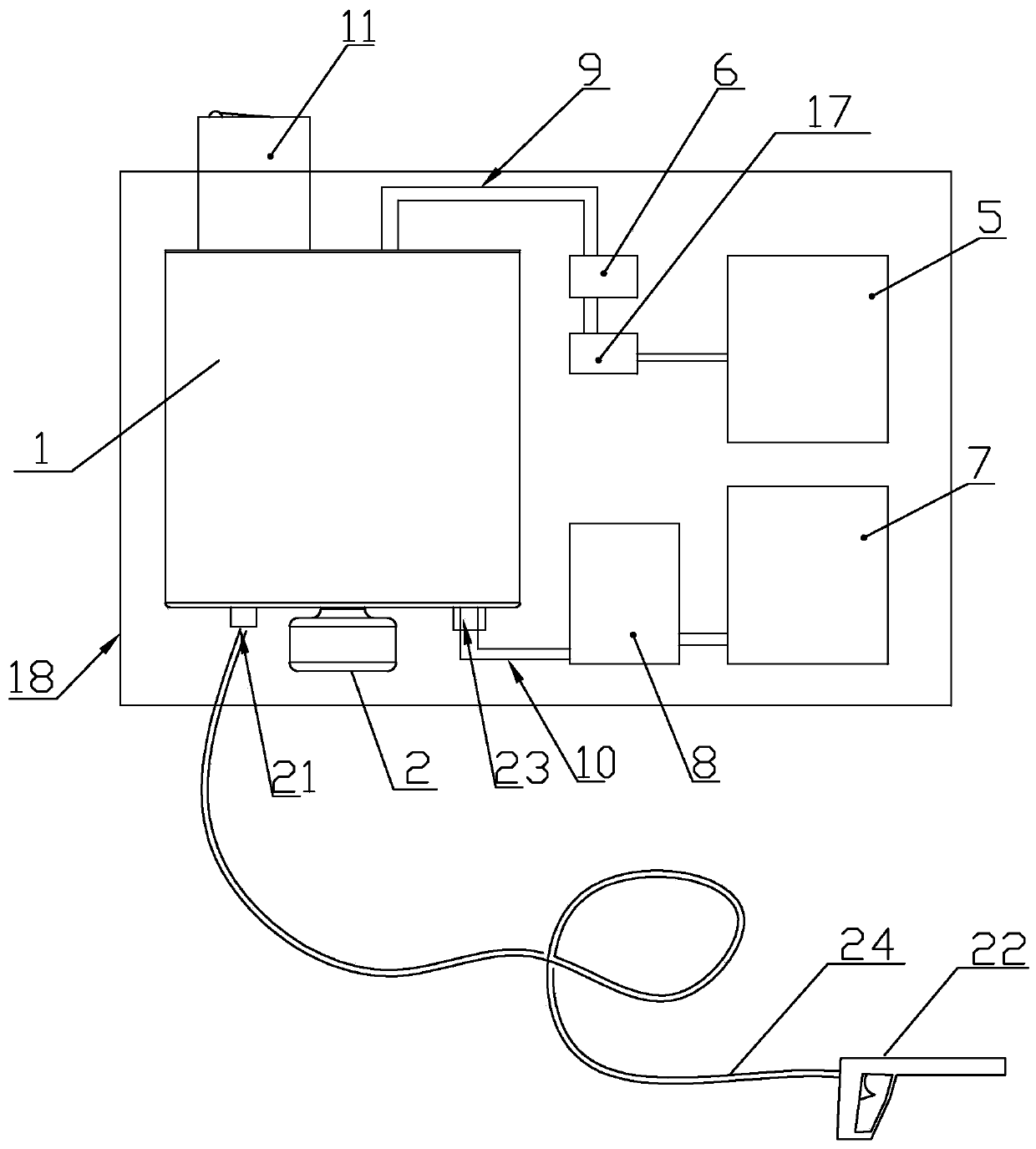

[0033] A waste heat recovery steam car washing machine based on alcohol-based fuel, including a combustion chamber 1, a fan 2, several spiral coils I3, at least one atomizing nozzle 4, a fuel storage tank 5, an electromagnetic pump 6, a water tank 7, a water pump 8, Ignition device 20 and steam spray gun 22, described fan 2 is installed on the bottom of combustion chamber 1, and the air outlet of described fan 2 communicates with combustion chamber 1, and all described atomizing nozzles 4 and ignition device 20 are all arranged in combustion chamber 1 Inside, all the atomizing nozzles 4 are connected to the outlet of the electromagnetic pump 6 arranged outside the combustion chamber 1 through the pipeline I9, and the inlet of the electromagnetic pump 6 is connected to the fuel storage tank 5 through the pipeline I9; the several The spiral coils I3 are connected in sequence and arranged inside the combustion chamber 1. The inlets of the several sequentially connected spiral coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com