A hydrocracking method for producing chemical raw materials

A technology for hydrocracking and chemical raw materials, which is applied in hydrotreating process, petroleum industry, processing hydrocarbon oil, etc., can solve the problem that the yield of heavy naphtha is not enough to meet the product demand, and the yield of light naphtha or light hydrocarbon is high. , increasing the complexity of the device, etc., to achieve the effects of excellent tail oil quality, small device investment and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

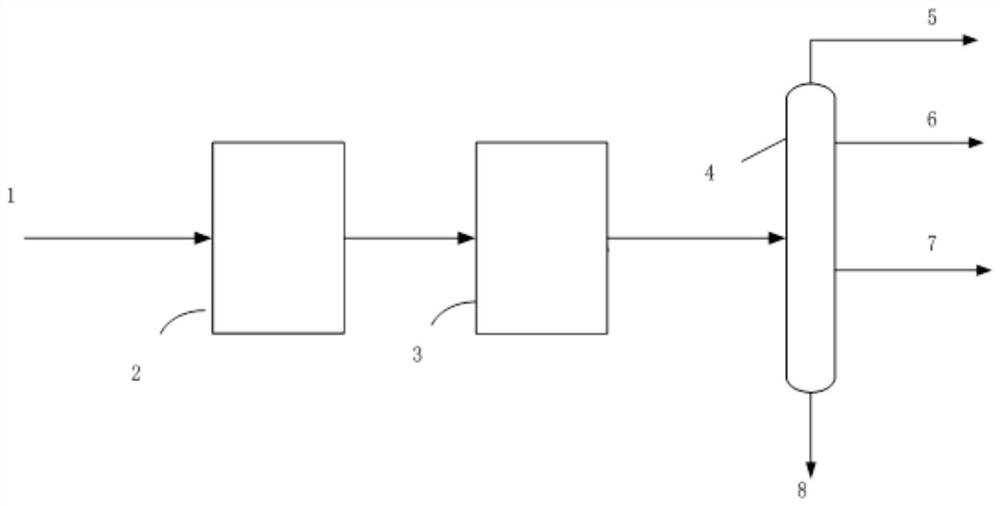

[0059] The following combination figure 1 A preferred embodiment of the hydrocracking method for producing chemical raw materials of the present invention is provided, the method comprising:

[0060] Put the hydrocracking raw material 1 and hydrogen into the hydrocracking reaction zone 2 for hydrocracking pretreatment, and then enter the hydrocracking reaction zone 3 for hydrocracking reaction after the hydrocracking pretreatment to obtain the hydrocracking effluent Then, the hydrocracking effluent is introduced into the separation and fractionation unit 4 for fractionation, so as to obtain a light naphtha fraction 5, a heavy naphtha fraction 6, a diesel fraction 7 and a tail oil fraction 8; wherein, the added The hydrocracking feedstock 1 contains a VGO fraction and a DAO fraction, and the DAO fraction accounts for 10-30% by weight of the total amount of the hydrocracking feedstock 1, and the partial pressure of hydrogen in the hydrocracking reaction zone 3 is 20-80% of the ...

Embodiment 1

[0073] Hydrogenation pretreatment catalyst RN-410 and hydrocracking catalyst RHC-210 are used, and hydrogenation pretreatment catalyst RN-410 is filled in the hydrogenation pretreatment reaction zone, and hydrocracking catalyst RHC-210 is filled in the hydrocracking reaction zone , with raw material 1 in table 1 as feed, in the production scheme of embodiment 1 (using figure 1 Shown technological process carries out) obtain light naphtha fraction, heavy naphtha fraction, diesel oil fraction and tail oil fraction under.

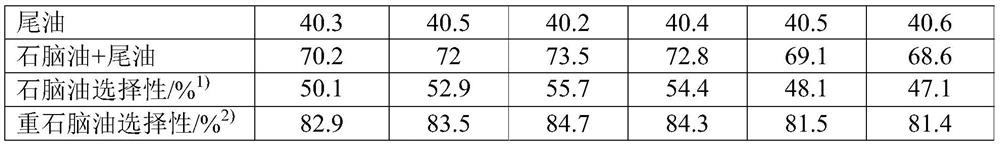

[0074] Process conditions, product distribution, and key product properties are listed in Tables 2 and 3.

[0075] As shown in Table 2 and Table 3, under the condition of medium pressure of hydrocracking hydrogen partial pressure of 11MPa and hydrocracking reaction temperature of 375°C, after raw material 1 undergoes cracking reaction by the method in Example 1, naphtha + The total yield of tail oil reaches 70.2%, the selectivity of naphtha is 50.1%, the sele...

Embodiment 2

[0086] Hydrogenation pretreatment catalyst RN-410 and hydrocracking catalyst RHC-210 are used, and hydrogenation pretreatment catalyst RN-410 is filled in the hydrogenation pretreatment reaction zone, and hydrocracking catalyst RHC-210 is filled in the hydrocracking reaction zone , with raw material 1 in table 1 as feed, in the production scheme of embodiment 2 (using figure 1 Shown technological process carries out) obtain light naphtha fraction, heavy naphtha fraction, diesel oil fraction and tail oil fraction under.

[0087] Process conditions, product distribution, and key product properties are listed in Tables 2 and 3.

[0088] As shown in Table 2 and Table 3, under the conditions of hydrocracking hydrogen partial pressure of 8 MPa and hydrocracking reaction temperature of 373°C, raw material 1 undergoes cracking reaction by the method in Example 2, naphtha + tail oil The total yield reaches 72.0%, the selectivity of naphtha is 52.9%, the selectivity of heavy naphtha fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com