Konjac glucomannan mite killing patch and preparation method thereof

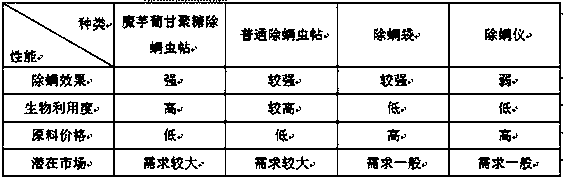

A technology of konjac glucomannan and glucomannan glue, which is applied in the fields of botanical equipment and methods, acaricides, rayon manufacturing, etc., can solve the problem of low bioavailability, insufficient comfort of plastic plates, and inconvenient use. and other problems, to achieve the effect of high mite removal efficiency, good drug-carrying effect, and easy portability and use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: A kind of preparation method of konjac glucomannan removing mite plaster, comprises the following steps:

[0027] (1) Preparation of konjac glucomannan glue: according to parts by mass, take 0.12 parts of rosin resin, 0.35 parts of polyvinyl alcohol, 0.03 parts of microcrystalline wax, 0.04 parts of terpene resin and 0.12 parts of phosphite. 1500r / min, under the condition of 85℃, add 95 parts of water successively, after stirring for 6h, adjust the pH to 7-11 with 1mol / L NaOH; then, add 1 part of konjac glucomannan, at 1500r / min, 85 Stir for 4 hours under the condition of ℃ to obtain the konjac glucomannan glue, which is set aside;

[0028] (2) Filtration: filter the konjac glucomannan adhesive prepared in step (1) with a filter screen with a diameter of 1 mm, and the filtrate is konjac glucomannan adhesive;

[0029] (3) Preparation of konjac glucomannan / chitosan nanofiber membrane: take 0.7 parts of konjac glucomannan and 0.5 parts of chitosan, add them ...

Embodiment 2

[0031] Embodiment 2: A kind of preparation method of konjac glucomannan removing mite plaster, comprises the following steps:

[0032] (1) Preparation of konjac glucomannan glue: prepared according to parts by mass, take 0.14 parts of rosin resin, 0.4 parts of polyvinyl alcohol, 0.05 parts of microcrystalline wax, 0.07 parts of terpene resin and 0.13 parts of phosphite, in 1500r / min, 90°C, add 98 parts of water successively, stir for 6 hours, adjust the pH to 7-11 with 1mol / L NaOH; then add 1 part of konjac glucomannan, at 1500r / min, 90°C Stir for 4.5h under the conditions to get konjac glucomannan glue, for subsequent use;

[0033] (2) Filtration: filter the konjac glucomannan adhesive prepared in step (1) with a filter screen with a diameter of 1 mm, and the filtrate is konjac glucomannan adhesive;

[0034] (3) Preparation of konjac glucomannan / chitosan nanofiber membrane: take 0.6 parts of konjac glucomannan and 0.4 parts of chitosan, add them to 99 parts of deionized water ...

Embodiment 3

[0036] Embodiment 3: a kind of preparation method of konjac glucomannan removes mite plaster, comprises the following steps:

[0037] (1) Preparation of konjac glucomannan glue: prepared according to parts by mass, take 0.15 parts of rosin resin, 0.45 parts of polyvinyl alcohol, 0.06 parts of microcrystalline wax, 0.12 parts of terpene resin and 0.16 parts of phosphite, in Add 100 parts of water successively at 1500r / min, 95°C, stir for 7 hours, adjust the pH to 7-11 with 1mol / L NaOH; then add 2 parts of konjac glucomannan, at 1500r / min, 95°C Stir for 5h under the condition of the konjac glucomannan to obtain the konjac glucomannan glue, for subsequent use;

[0038] (2) Filtration: filter the konjac glucomannan adhesive prepared in step (1) with a filter screen with a diameter of 1 mm, and the filtrate is konjac glucomannan adhesive;

[0039] (3) Preparation of konjac glucomannan / chitosan nanofiber membrane: Take 0.8 parts of konjac glucomannan and 0.6 parts of chitosan in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com