Preparation method of conductive hydrogel sensor based on polyacrylamide-silk fibroin

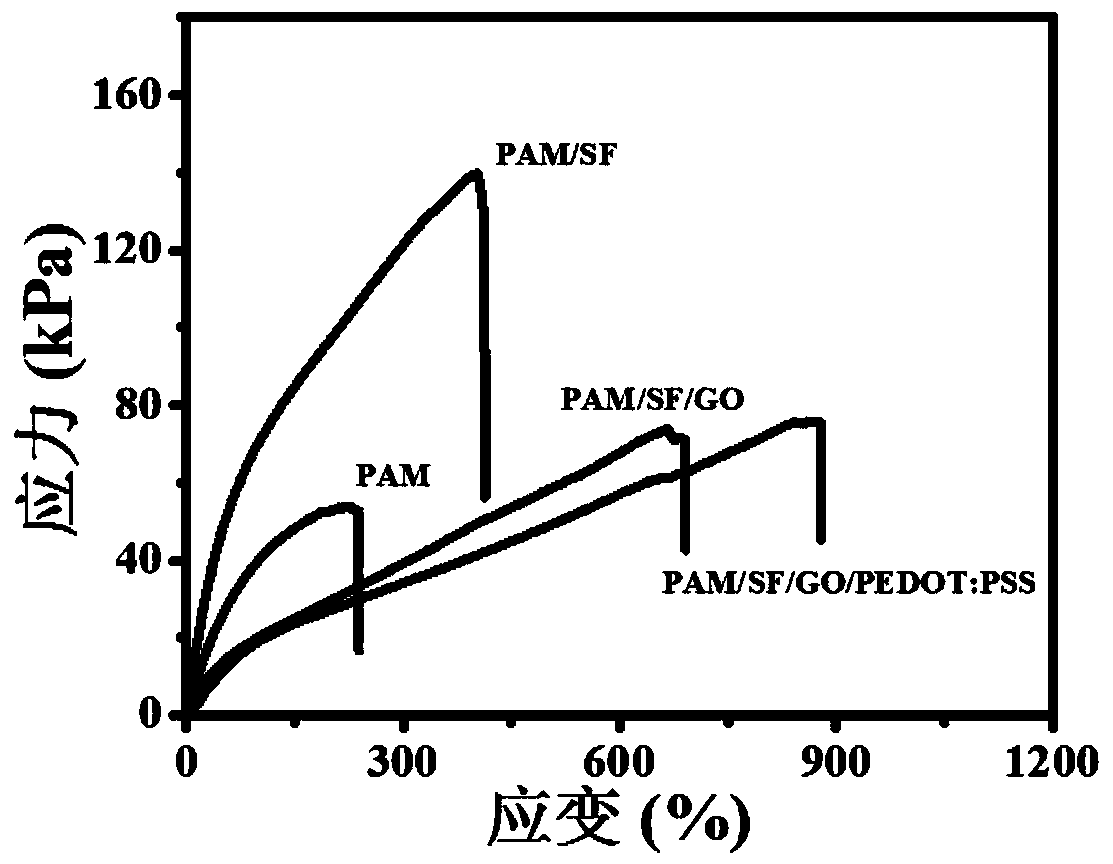

A technology of polyacrylamide and conductive hydrogel, which is applied in the direction of instruments, electromagnetic measuring devices, electric/magnetic solid deformation measurement, etc., can solve the problem that the tensile and compressive signals cannot be tested at the same time, and cannot be used to distinguish signals at the same time, acrylic Solve the problems of poor mechanical properties of amide, and achieve the effect of excellent resistance response, sensitive response and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1) Cut the cocoon layer of the silkworm cocoons after removing the pupae into small pieces of 1cm×1cm, put them in a boiling solution of 7.5g / L sodium bicarbonate and boil them, and repeat the cooking 3 times. The obtained silk fibroin fiber was dried in an oven at 55°C, and the dried silk fibroin fiber was dissolved in a 9.3M lithium bromide solution, and the obtained solution was dialyzed in deionized water for three days, and the water was changed every 4 hours The lithium bromide component in the solution is removed to obtain a silk fibroin solution.

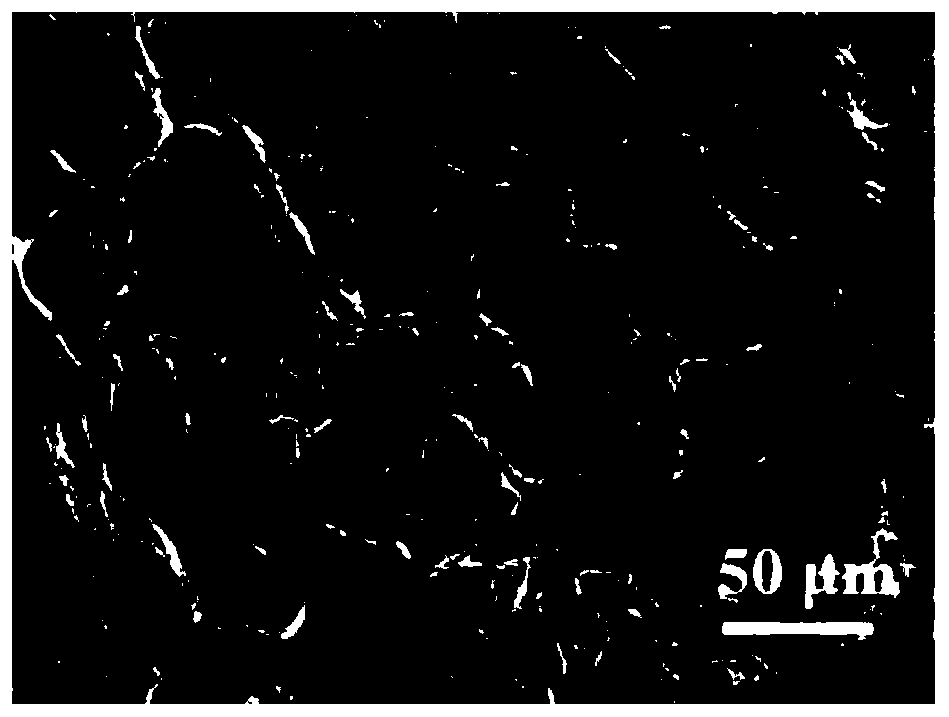

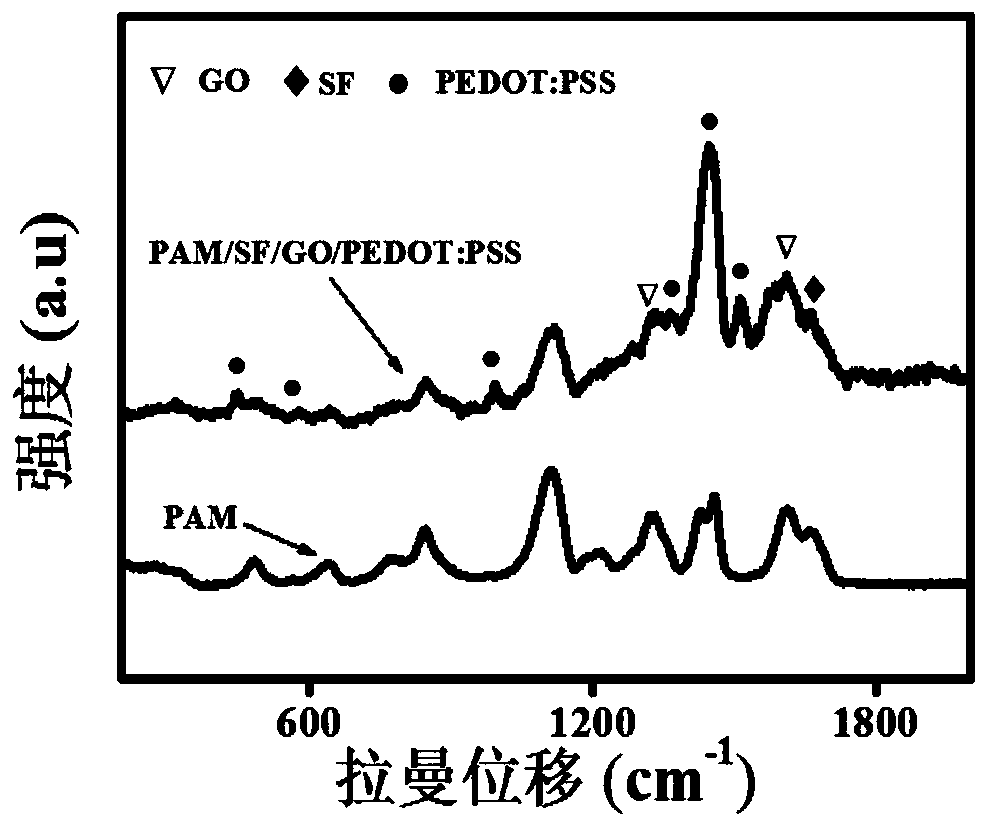

[0026] 2) First, 30 g of acrylamide was dissolved in 70 ml of deionized water, and 0.1 g of ammonium persulfate and 0.05 g of N, N'-methylenebisacrylamide were added to obtain a polyacrylamide solution. Then add the graphene oxide solution that 10ml concentration is 3mg / ml in the polyacrylamide solution, 10ml is obtained by the silk fibroin solution in 1), and 3ml concentration is the poly-3 of 10mg / ml, 4-ethylenediox...

Embodiment 2

[0028] 1) Cut the cocoon layer of the silkworm cocoons after removing the pupae into small pieces of 1cm×1cm, put them in a boiling solution of 7.5g / L sodium bicarbonate and boil them, and repeat the cooking 3 times. The obtained silk fibroin fiber is dried in an oven at 60°C, and the dried silk fibroin fiber is dissolved in a 9.3M lithium bromide solution, and the obtained solution is dialyzed in deionized water for three days, and the water is changed every 4 hours The lithium bromide component in the solution is removed to obtain a silk fibroin solution.

[0029] 2) Dissolve 30g of acrylamide in 70ml of deionized water, add 0.1g of ammonium persulfate, 0.05g of N, N'-methylenebisacrylamide and stir well to obtain a polyacrylamide solution.

[0030] 3) Repeat the step of 2) in Example 2, then add 20 ml of the silk fibroin solution obtained in 1) of Example 2 to the polyacrylamide solution and stir evenly to obtain a polyacrylamide / silk fibroin solution.

[0031] 4) Repeat t...

Embodiment 3

[0035] 1) Cut the cocoon layer of the silkworm cocoons after removing the pupae into small pieces of 1cm×1cm, put them in a boiling solution of 7.5g / L sodium bicarbonate and boil them, and repeat the cooking 3 times. The obtained silk fibroin fiber was dried in an oven at 65°C, and the dried silk fibroin fiber was dissolved in a 9.3M lithium bromide solution, and the obtained solution was dialyzed in deionized water for three days, and the water was changed every 4 hours The lithium bromide component in the solution is removed to obtain a silk fibroin solution.

[0036] 2) Dissolve 30g of acrylamide in 70ml of deionized water, add 0.1g of ammonium persulfate, 0.05g of N, N'-methylenebisacrylamide and stir well to obtain a polyacrylamide solution.

[0037] 3) repeat the steps of 2) in Example 3, then add 50ml in the polyacrylamide solution by 1) the silk fibroin solution obtained in Example 2, 30ml concentration is the graphene oxide solution of 3mg / ml, 10ml is obtained by 1) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com