Benzoxazine modified epoxy resin insulating material and epoxy casting insulating member and preparation method thereof

A benzoxazine and epoxy resin technology, applied in plastic/resin/wax insulators, insulators, organic insulators, etc., can solve the problem that mechanical properties and insulation properties cannot meet the requirements of miniaturization of insulators, and the miniaturization of supporting insulators It can reduce the maintenance and overhaul costs of power stations, improve reliability and service life, and have excellent heat resistance performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

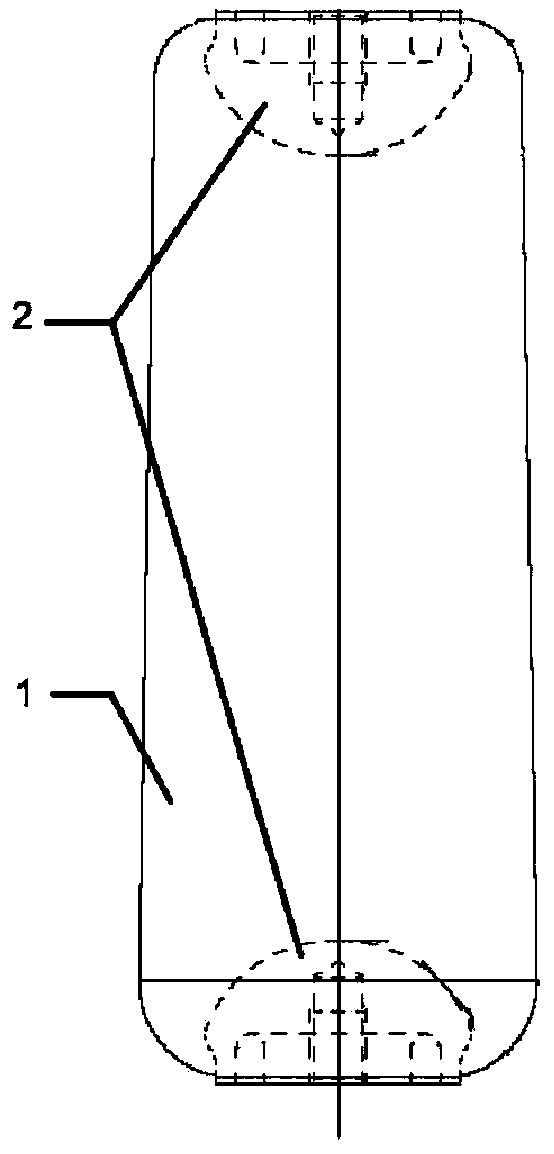

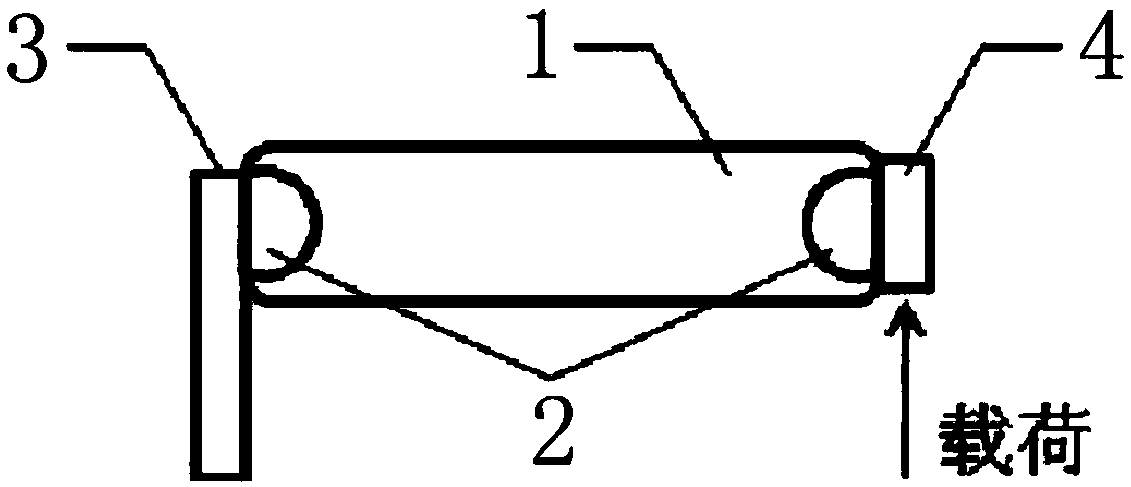

Image

Examples

Embodiment 1

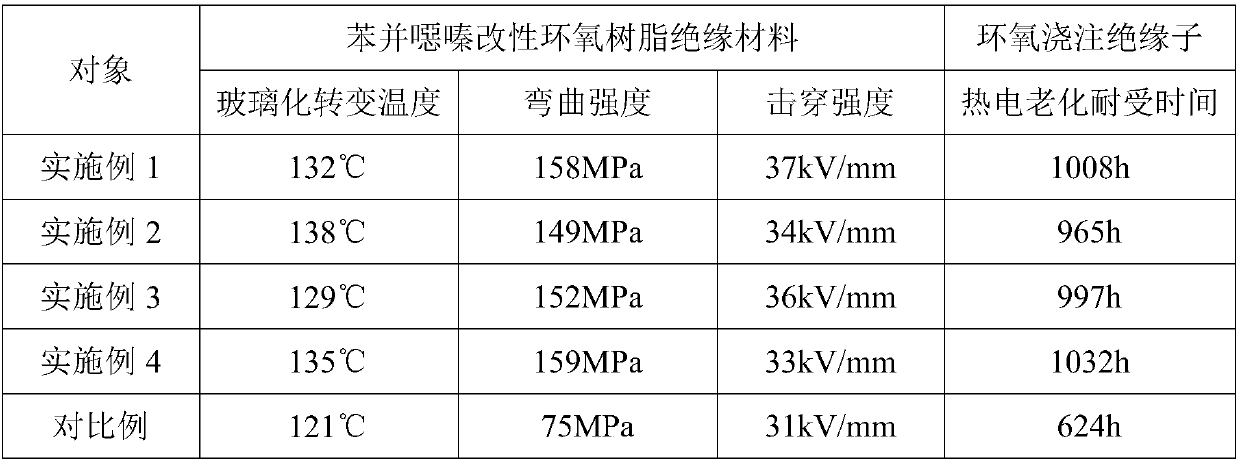

[0044] The benzoxazine-modified epoxy resin insulating material of this embodiment is made of a mixture of bisphenol A benzoxazine resin and epoxy resin, and the mixture of bisphenol A benzoxazine resin and epoxy resin The mass ratio is 1:4.7; the epoxy resin compound is made up of bisphenol A type epoxy resin, curing agent methyltetrahydrophthalic anhydride and A-F-3 type alumina filler, bisphenol A type epoxy resin, curing The mass ratio of methyl tetrahydrophthalic anhydride to A-F-3 alumina filler is 1:0.50:3.2. The bisphenol A type epoxy resin is CY5995.

[0045] The bisphenol A type benzoxazine resin is prepared by mixing component 1, component 2 and component 3 according to the mass ratio of 1:2.5:6.5; wherein, component 1 is benzoxazine KB4170; Component two is benzoxazine KB6100; component three is benzoxazine KB7165. Mix component 1, component 2 and component 3 in proportion in advance to prepare bisphenol A type benzoxazine resin for later use.

[0046] The epoxy...

Embodiment 2

[0055] The benzoxazine-modified epoxy resin insulating material of this embodiment is made of a mixture of bisphenol A benzoxazine resin and epoxy resin, and the mixture of bisphenol A benzoxazine resin and epoxy resin The mass ratio is 1:4.96; the epoxy resin compound is made up of bisphenol A type epoxy resin, curing agent methyltetrahydrophthalic anhydride and A-F-4 type alumina filler, bisphenol A type epoxy resin, curing The mass ratio of methyl tetrahydrophthalic anhydride to A-F-4 alumina filler is 1:0.56:3.4. Described bisphenol A type epoxy resin is EPIKOTE TM Resin 805.

[0056] The bisphenol A type benzoxazine resin is prepared by mixing component 1, component 2 and component 3 according to the mass ratio of 1:2.5:6.5; wherein, component 1 is benzoxazine KB4170; Component two is a mixture of benzoxazine KB6100 and KB6600 at a mass ratio of 1:1; component three is benzoxazine KB7170. Mix component 1, component 2 and component 3 in proportion in advance to prepare...

Embodiment 3

[0066] The benzoxazine-modified epoxy resin insulating material of this embodiment is made of a mixture of bisphenol A benzoxazine resin and epoxy resin, and the mixture of bisphenol A benzoxazine resin and epoxy resin The mass ratio is 1:4.85; the epoxy resin mixture is made up of bisphenol A type epoxy resin, curing agent methyltetrahydrophthalic anhydride and A-F-5 type alumina filler, bisphenol A type epoxy resin, curing The mass ratio of methyl tetrahydrophthalic anhydride to A-F-5 alumina filler is 1:0.52:3.3. The bisphenol A type epoxy resin is CT200M.

[0067] The bisphenol A type benzoxazine resin is prepared by mixing component 1, component 2 and component 3 according to the mass ratio of 1:2.5:6.5; wherein, component 1 is benzoxazine KB4170; Component two is benzoxazine KB6600; component three is a mixture of benzoxazine KB7200, KB7280 and KB7290 with a mass ratio of 1:1:1. Mix component 1, component 2 and component 3 in proportion in advance to prepare bisphenol ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com