Reaction type water-based color paste and preparation method thereof

A water-based color paste, reactive technology, applied in the direction of pigment paste, etc., can solve the problems affecting the fluid properties of color paste products, the impact of coating water resistance, poor water solubility, etc., to achieve excellent storage stability and avoid floating color , the effect of good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

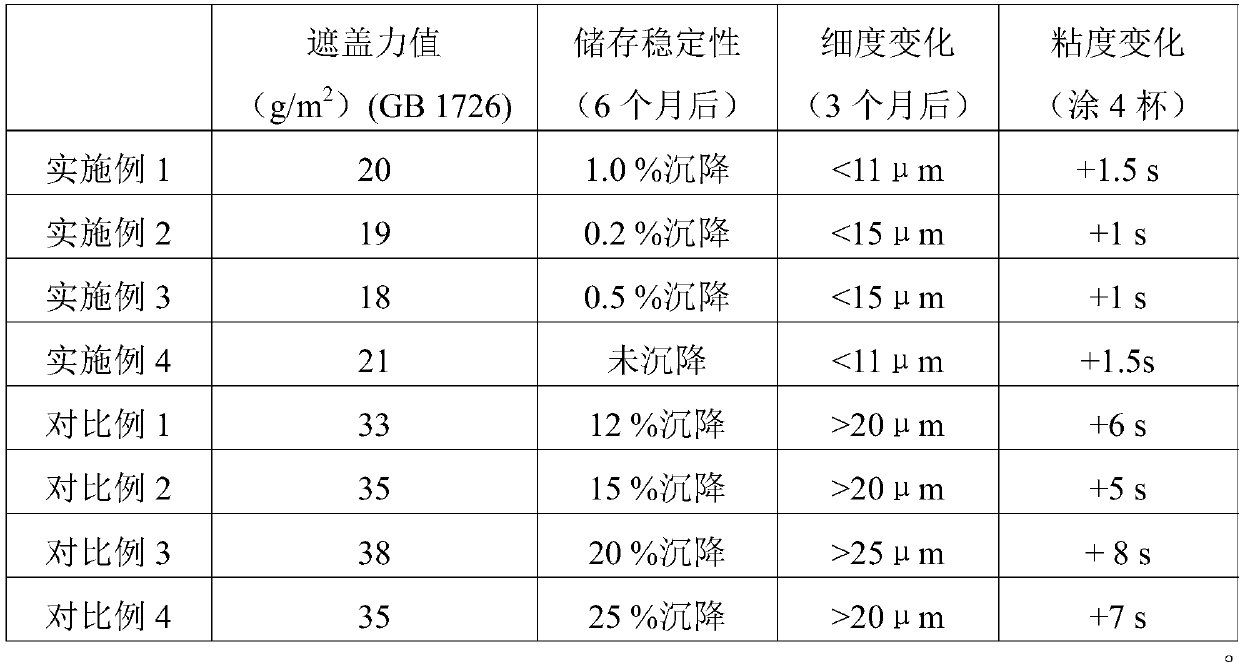

Embodiment 1

[0034] The preparation of styrene-maleic anhydride copolymer polyether ester: be 30% styrene-maleic anhydride copolymer (molecular weight is 2000, molecular weight distribution index is 1.5) and monomethyl end-capped polyethylene with maleic anhydride mole fraction Diol (molecular weight 2500) was mixed according to maleic anhydride and polyethylene glycol 1:1 (molar ratio), stirred evenly, 1 wt% p-toluenesulfonic acid was added, heated to 120°C, and reacted for 6h. Add hydroxylated pigment (the hydroxyl content is equal to the molar amount of maleic anhydride), raise the temperature to 130°C, continue the reaction for 2.0h, add ammonia solution, adjust the pH to 7.0, add water to adjust the viscosity to 50s (coat 4 cups). Obtained reactive water-based color paste (1).

Embodiment 2

[0036]The preparation of styrene-maleic anhydride copolymer polyether ester: be 80% styrene-maleic anhydride copolymer (molecular weight is 10000, molecular weight distribution index is 1.0) and the polypropylene glycol of monomethyl capping with maleic anhydride mole fraction (Molecular weight is 400) Mix maleic anhydride and polypropylene glycol 1:1 (molar ratio), stir evenly, add 5wt% p-toluenesulfonic acid, heat to 100°C, and react for 2.0h. Add hydroxylated carbon black pigment (the hydroxyl content is equal to the molar amount of maleic anhydride), raise the temperature to 150°C, continue the reaction for 6.0h, add diethanolamine aqueous solution, adjust the pH to 8.0, and add water to adjust the viscosity to 20s (coat 4 cups). Acquired reactive water-based color paste (2).

Embodiment 3

[0038] The preparation of styrene-maleic anhydride copolymer polyether ester: the styrene-maleic anhydride copolymer (molecular weight is 1000, and molecular weight distribution index is 2.0) and monomethyl-terminated copolymerization of maleic anhydride mole fraction is 50% Ether (molecular weight is 1000, propylene glycol: ethylene glycol molar ratio = 1:1) is mixed with maleic anhydride and monomethyl terminated copolyether 1:0.1 (molar ratio), stirred evenly, and added 5wt% p-methyl Benzenesulfonic acid, heated to 150 ° C, reacted for 6.0h. Add hydroxylated carbon black pigment (the hydroxyl content is equal to twice the molar amount of maleic anhydride), raise the temperature to 150°C, continue the reaction for 4.0h, add triethanolamine ethanol solution, adjust the pH to 6.0, add water to adjust the viscosity to 30s (coat 4 cups ). Acquired reactive water-based color paste (3).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com