Reject recovery reverse osmosis (R2RO)

A technology of reverse osmosis and permeate, which is applied in the field of waste recovery and reverse osmosis R2RO treatment. It can solve the problems that the waste stream cannot be disposed of, the concentrated stream is not suitable, and the environment of water loss, so as to save capital costs, prevent precipitation, The effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

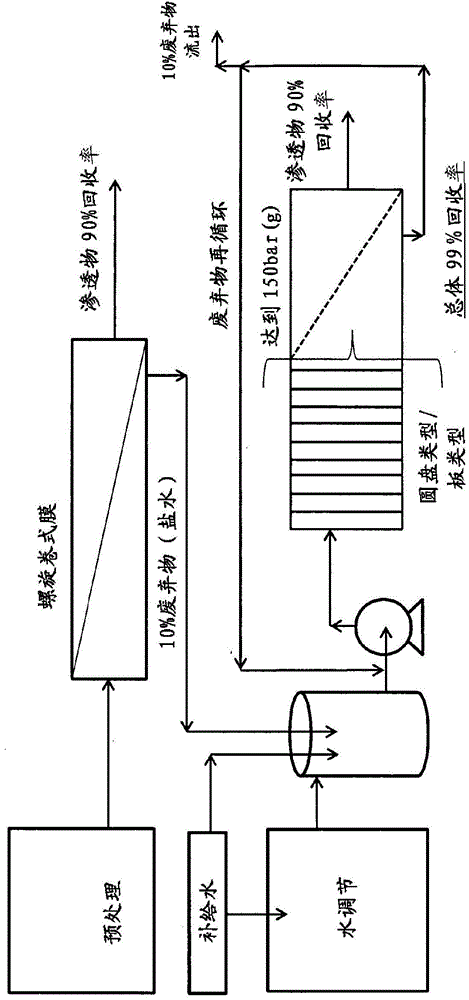

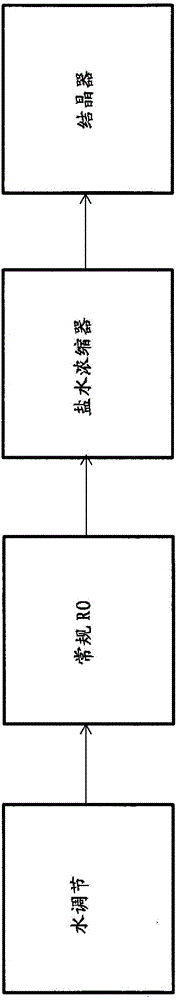

[0032] The invention is made possible through the following innovative processing methods:

[0033] 1. The waste is pre-conditioned to reduce or remove ions, which cause fouling. The pre-conditioning system is designed to remove fouling salts, which are likely to cause fouling and limit the recovery rate based on water chemistry. This can be hard, silica or any other inorganic salt. This treatment may involve purification design and related equipment such as filter presses or centrifuges and pumps along with lime, soda ash, magnesium oxide, ferric chloride or alkali dosing systems.

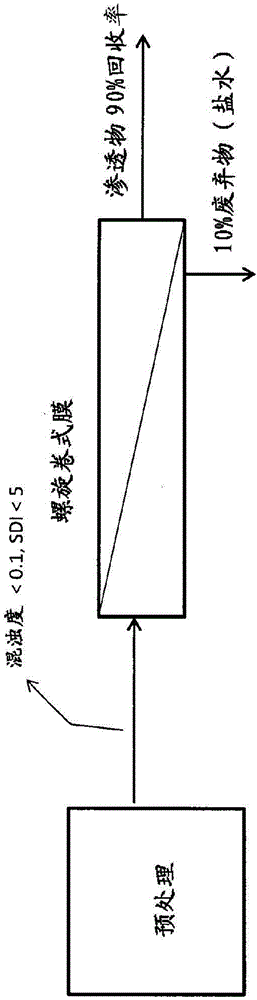

[0034] 2. Any precipitate formed is separated and disposed of separately. Due to the presence of oil or organic matter, purified water may still have turbidity. For conventional reverse osmosis, this pretreatment level is considered inappropriate, in which turbidity of less than 0.1 NTU and SDI of less than 5 are desired and less than 3 is preferred.

[0035] 3. In a particular embodiment of this met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com