Making method of aged vinegar

An old mature vinegar and aging technology, applied in the preparation of vinegar and other directions, can solve the problems of high production cost, easy to produce flocculent precipitation, etc., and achieve the effects of reducing the production amount, reducing the production of tannin, and improving the quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

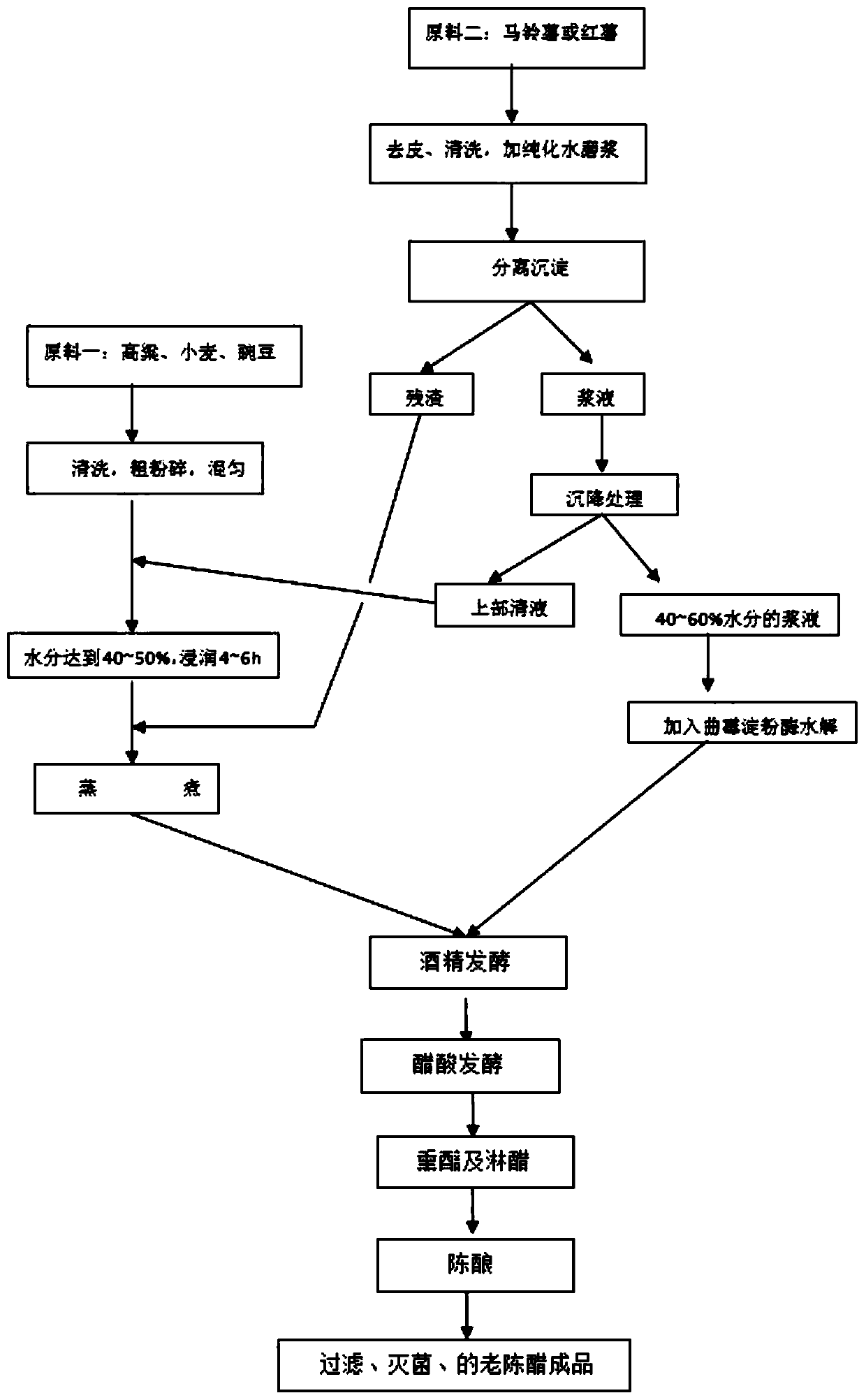

[0039] Please refer to figure 1 as shown, figure 1 It is a process diagram of brewing mature vinegar of the present invention. In this embodiment, the brewing method of mature vinegar includes the following steps: raw material processing, auxiliary material processing, starch hydrolysis, alcohol fermentation, acetic acid fermentation, smoked grains and vinegar, aging .

[0040] Among them, raw material processing includes the following steps:

[0041] Step 1.1: Raw material 1, choose high-quality, impurity-free, and mildew-free sorghum, wheat, and peas in proportion, wash and coarsely grind, mix well, and set aside; raw material 2, choose potatoes or sweet potatoes, peel and wash, Add purified water to refine the pulp, separate the slurry and residue, and set aside. Wherein, the mass of raw material 2 is 1.5 to 3 times the mass of raw material 1, and in this embodiment, preferably, the mass of raw material 2 is 2.5 times that of raw material 1.

[0042] Step 1.2: Settling ...

Embodiment 2

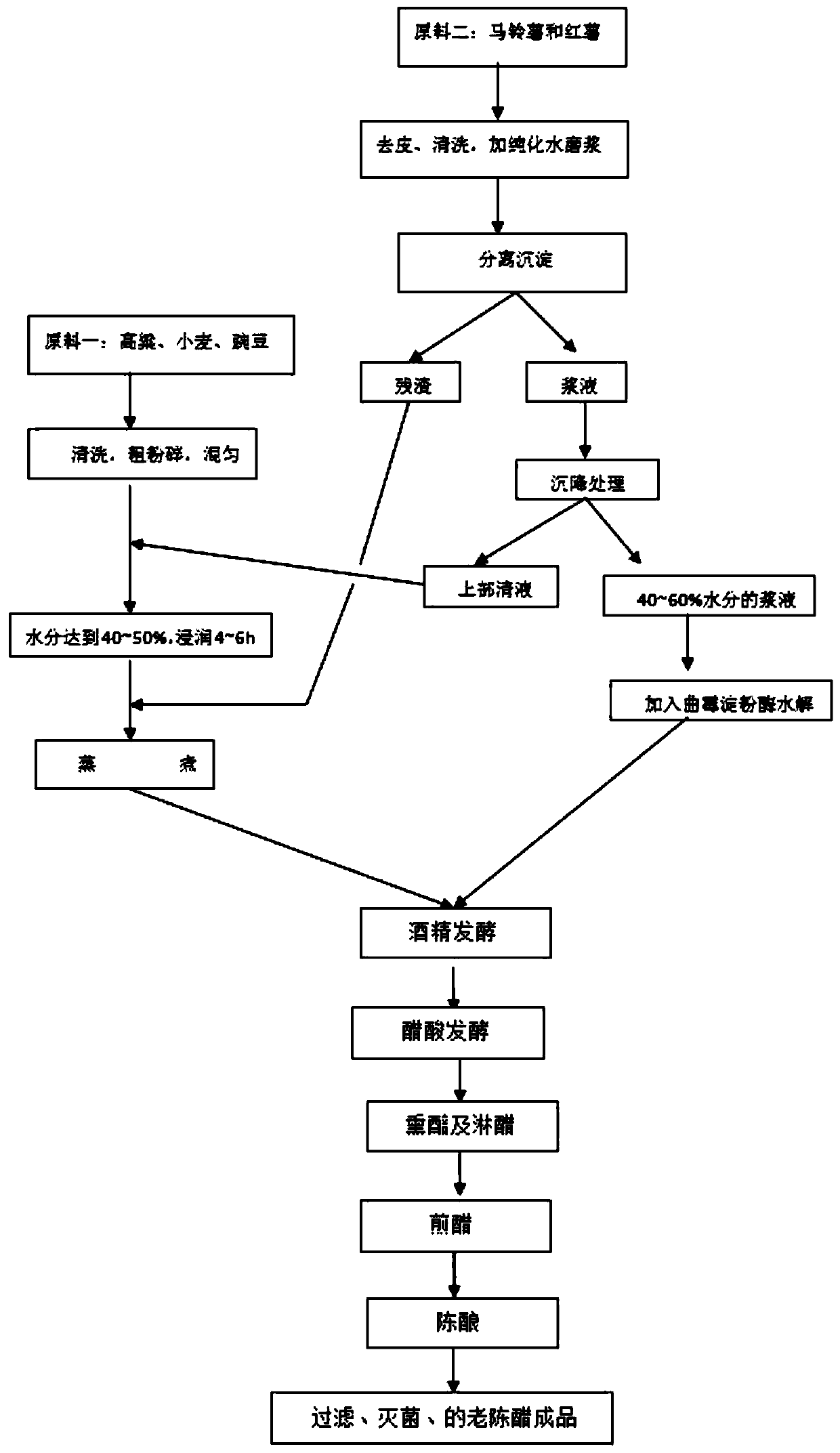

[0061] Please refer to figure 2 as shown, figure 2 It is a process diagram of brewing another mature vinegar of the present invention. The difference between this example and Example 1 is that tartary buckwheat is added to raw material 1, and tartary buckwheat stalks are also added to the alcoholic fermentation product in the acetic acid fermentation. Tartary buckwheat is rich in functional active substances such as bioflavonoids, D-chiro-inositol, polyphenols, γ-aminobutyric acid, selenium, etc., and the content of flavonoids is 2.19-4.02%. Blood lipids, scavenging free radicals in the body, anti-cancer and anti-cancer effects. Adding tartary buckwheat to the raw materials for brewing mature vinegar can increase the content of functional components such as total flavonoids and monacolin K in mature vinegar and meet people's daily needs.

[0062] In this embodiment, the brewing method of mature vinegar includes the following steps: raw material processing, auxiliary mater...

Embodiment 3

[0082] This example provides the preparation and processing methods of various auxiliary materials in Example 1 and Example 2. The auxiliary material processing includes the preparation of Daqu, Xiaoqu auxiliary materials, bran koji auxiliary materials, red yeast rice auxiliary materials, wheat koji auxiliary materials, and Aspergillus amylase auxiliary materials .

[0083] Daqu preparation: Take sorghum, wheat, and peas, grind them, mix them, add purified water to infiltrate them, and step on the koji. In embodiment 2, when preparing Daqu, also need to add certain proportion tartary buckwheat.

[0084] The preparation of small koji auxiliary materials, gluten koji auxiliary materials, red koji auxiliary materials, wheat koji auxiliary materials, Aspergillus amylase auxiliary materials and other auxiliary materials are all carried out by traditional methods, and no further description is given here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com