Method and pre-oxidation furnace for regulating and controlling homogenization of carbon fiber pre-oxidized filaments

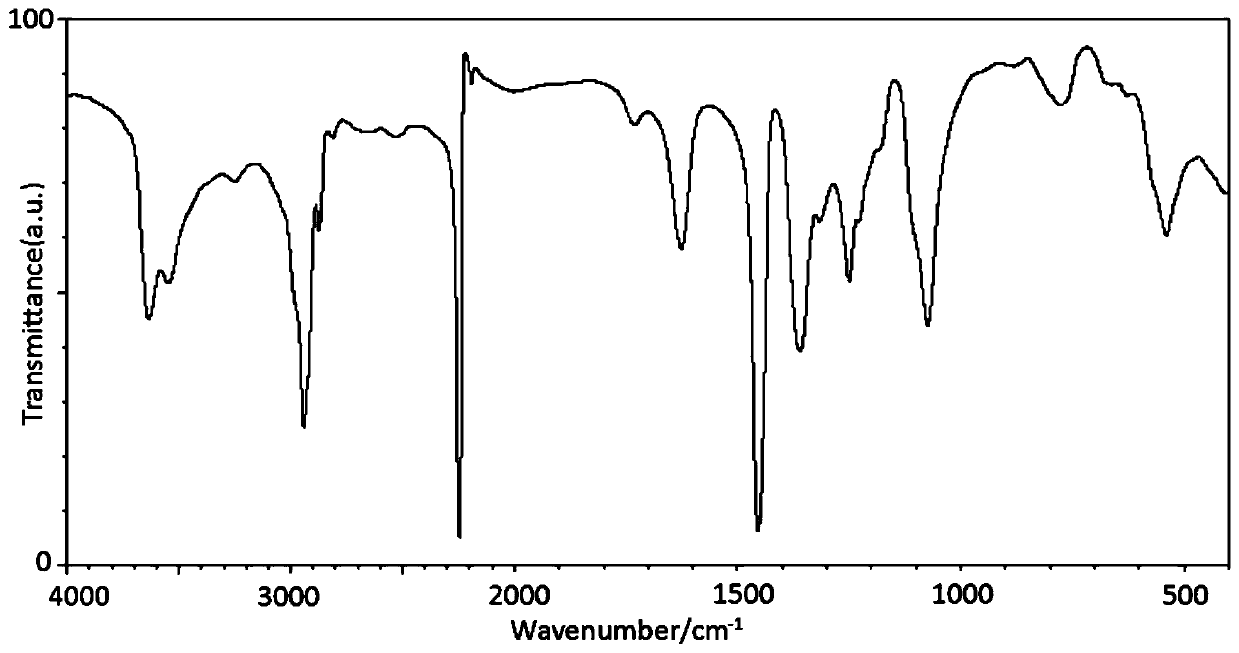

A technology of pre-oxidation furnace and pre-oxidation yarn, which is applied in the fields of fiber chemical characteristics, textiles and paper making, and can solve the problems of affecting the cyclization reaction inside the fiber, affecting the mechanical properties of carbon fiber, hindering oxygen diffusion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

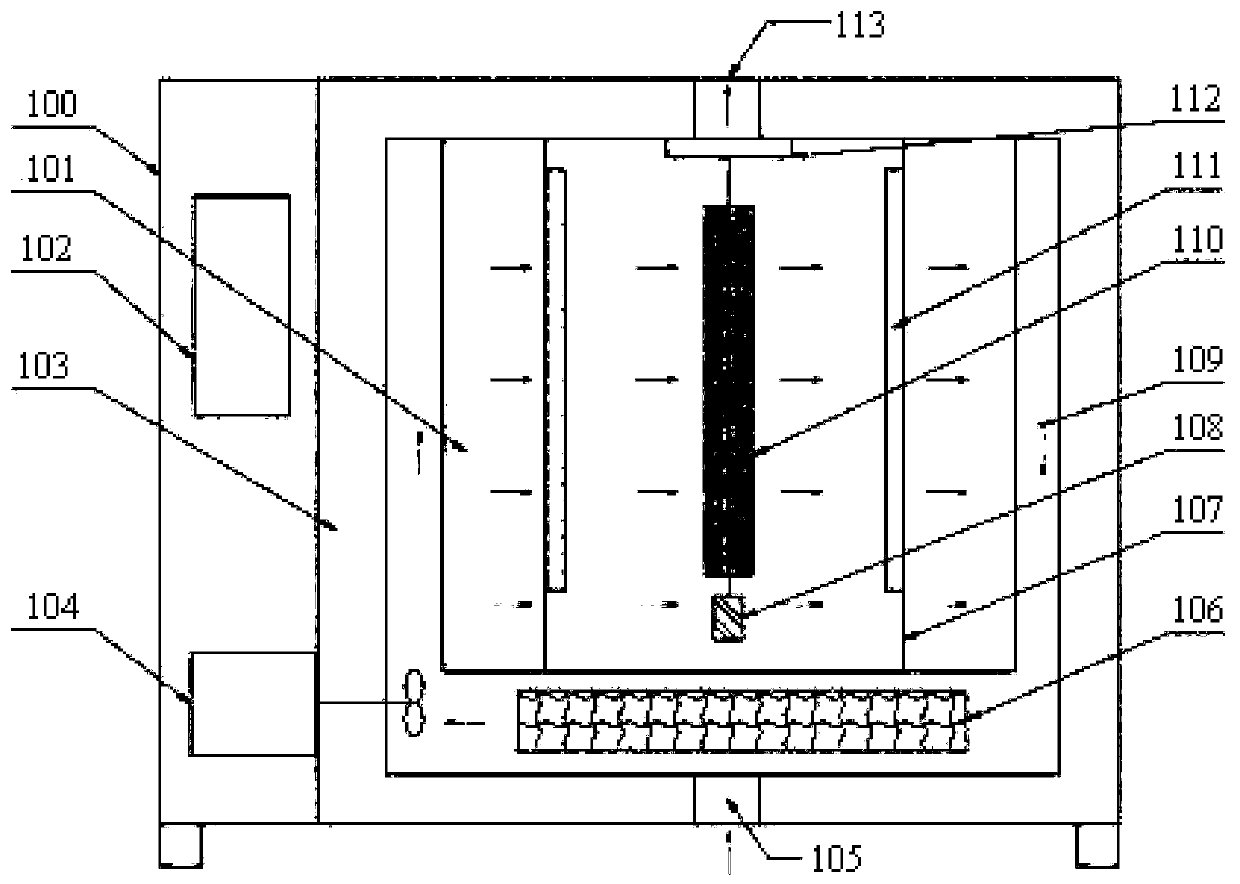

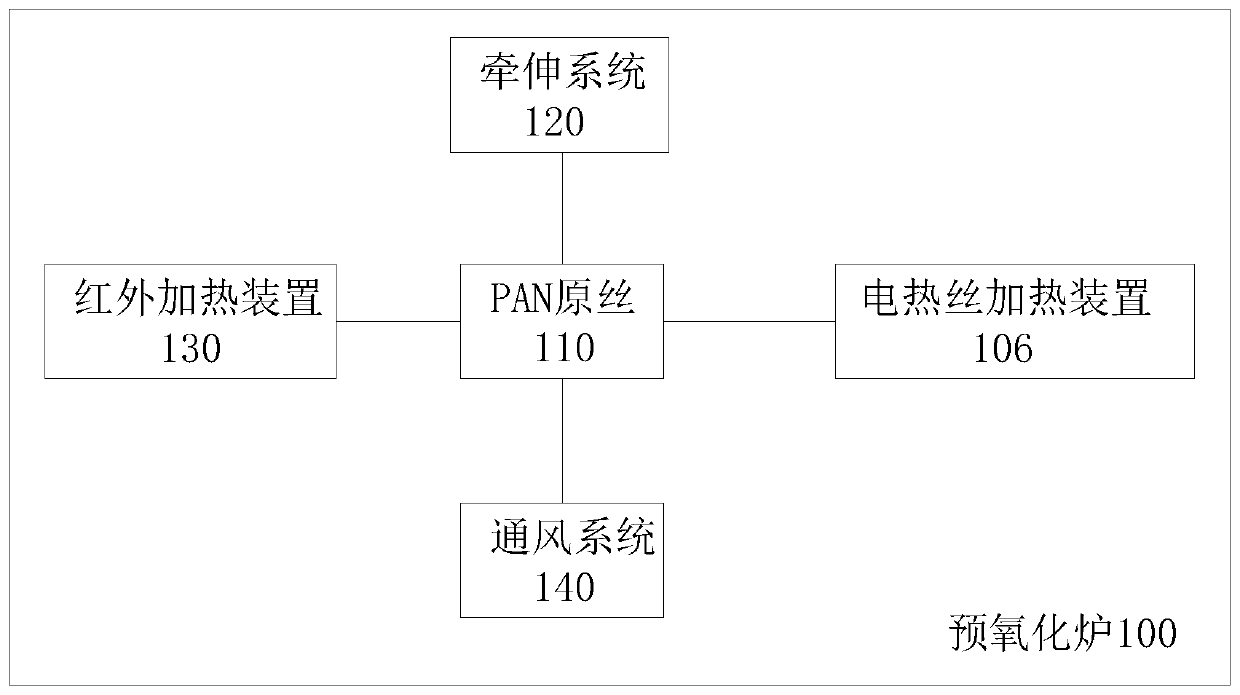

[0060] This embodiment provides a carbon fiber, which uses figure 2 The pre-oxidation furnace 100 shown is prepared according to the following preparation method:

[0061] Put the 1m-long PAN original yarn 110 (tensile strength 500MPa) evenly on the original yarn hanger 112, hang a certain weight on the lower end of the PAN original yarn 110 as a drafting load 108 (0.08g / d), infrared The heating tube 111 selects a medium-wave infrared transmitter with a power of 5 KW, a length of 1.5 meters, and a peak wavelength of 2.7 μm, and the temperature is controlled by a thyristor and an infrared thermometer. The heating temperature gradient of PAN raw yarn 110 is 180℃, 200℃, 215℃, 230℃, 240℃, 250℃, 260℃, 270℃, 275℃, a total of 9 heating gradients, and the corresponding holding time is 10 minutes. The temperature rise rate between gradients is controlled at 1~5℃ / min, and the temperature difference is controlled at ±3℃. The temperature difference between the circulating air temperature i...

Embodiment 2

[0064] This embodiment provides a carbon fiber, the preparation method of which is roughly the same as that of Example 1, except that the drafting tension is 0.20 g / d, and the carbon fiber is finally obtained. A total of 3 sets of parallel samples were made, namely parallel sample 1, parallel sample 2, and parallel sample 3.

[0065] Table 2 The main performance indicators of carbon fiber under different pre-oxidation conditions

[0066]

[0067] In summary, the method for regulating the homogenization of carbon fiber pre-oxidized filaments and the pre-oxidizing furnace in the embodiments of the present invention use infrared heating inside the fiber, hot air heating the outer layer of the fiber, combined with the convection temperature control fiber outer layer, to ensure that oxygen flows into the fiber The permeation of the pre-oxygenated wire finally achieves the goal of regulating the homogenization of the pre-oxygenated wire.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com