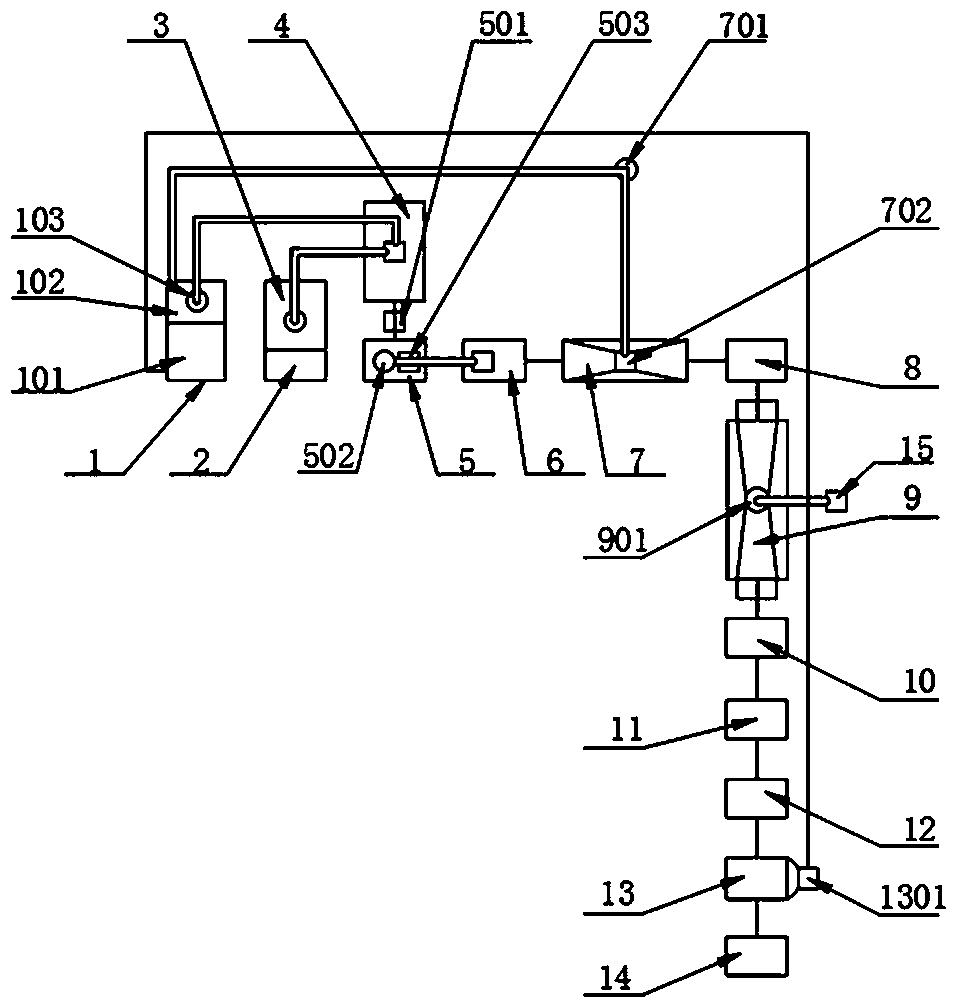

Sound-absorbing cotton production line

A production line, sound-absorbing cotton technology, applied in textiles and papermaking, fiber processing, fabric surface trimming, etc., can solve the problems of uneven thickness of sound-absorbing cotton grey cloth, rough surface, small hidden troubles, etc., to achieve the workshop environment and staff friendly, The effect of purifying the air environment and reducing the hidden danger of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0035] The implementation mode is as follows: the specific process of producing sound-absorbing cotton in this production line is as follows: S1. Bundled cotton bales of low-melting-point PET fiber and high-strength PET fiber are alternately placed on the conveying curtain of weighing bale opener 2 to open the bales and electronically weighed. Loosening machine 3, wherein the weight portion of the low-melting point PET fiber is 25% to 35%, and the weight portion of the high-strength PET fiber is 65% to 75%;

[0036] S2. The rough opener 3 performs preliminary opening on the raw materials sent by the symmetrical re-opener 2, and then sends the coarsely opened fibers into the cotton blender 4 through the air delivery pipeline;

[0037] S3. The cotton mixing machine 4 mixes the two kinds of coarsely opened fiber incoming materials in the mixing chamber, and the cotton storage in the mixing chamber can be monitored by manual observation and photoelectric detection; the coarse op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com