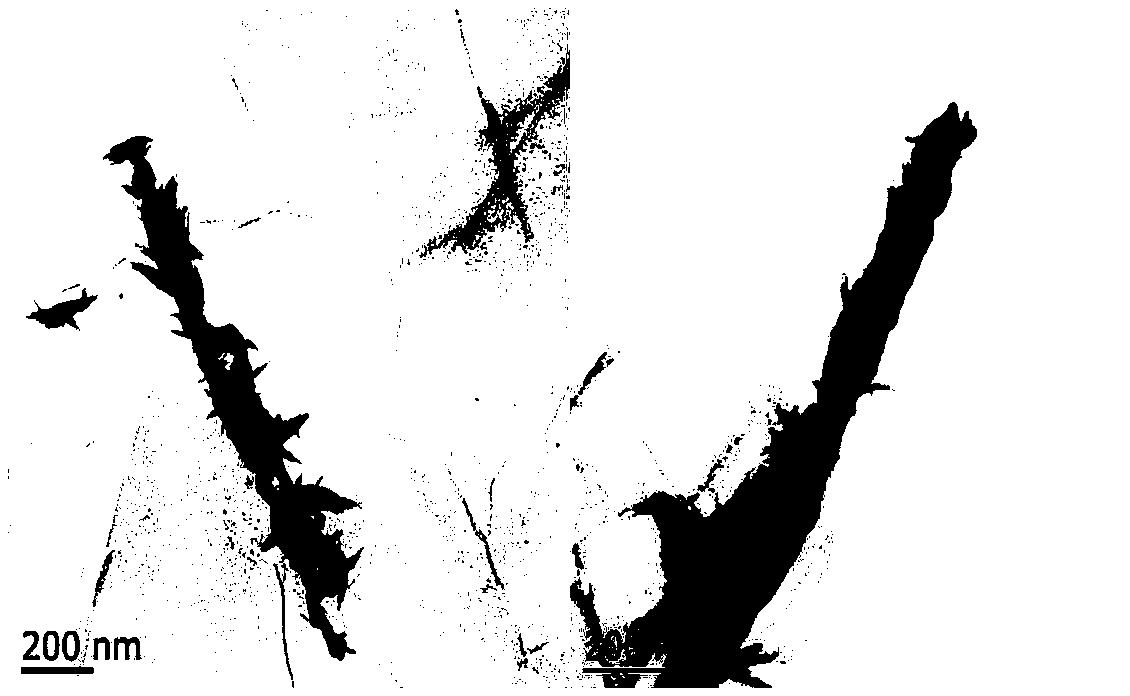

Method for preparing low-sensitivity copper azide by compounding rGO and copper nano-wires

A technology of copper nanowires and copper nitride, which is applied in the field of preparation of micro-nano energetic materials, can solve problems such as high sensitivity, and achieve the effects of improved reaction efficiency, simple reaction device, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Prepare 300mL of 15mol / mL NaOH solution, 30mL of 0.1mol / mL Cu(NO 3 ) 2 Solution, ultrasonically disperse graphene oxide in 15 mL of water with a concentration of 5 mg / mL. Put Cu(NO 3 ) 2 The solution was added to the graphene oxide aqueous solution, magnetically stirred for 30 minutes, the solution changed from light blue to light brown; 15mL of EDA was added and stirred for 15 minutes, until the solution turned purple; the mixed solution was added to the NaOH (300mL, 15mol / mL) ) In a three-necked flask, continue to stir for 10 min, the solution gradually turns blue; place in a water bath, heat to 80 ℃, the reaction time is 1h. 0.6g of catechin hydrate was added to the reaction solution, and ultrasonicated for 10 minutes, the solution changed from blue to dark gray; heated in a water bath at 80°C for 1 hour. Centrifuge the product, repeat washing and collection several times; then repeat washing with absolute ethanol, and store the obtained reduced graphene oxide-modifie...

Embodiment 2

[0044] Prepare 300mL of 20mol / mL NaOH solution, 30mL of 0.1mol / mL Cu(NO 3 ) 2 Solution, ultrasonically disperse graphene oxide in 20 mL of water with a concentration of 6 mg / mL. Put Cu(NO 3 ) 2 The solution was added to the graphene oxide aqueous solution, magnetically stirred for 30 minutes, the solution changed from light blue to light brown; 15mL of EDA was added and stirred for 15 minutes, until the solution turned purple; the mixed solution was added to the NaOH (300mL, 15mol / mL) ) In a three-necked flask, continue to stir for 10 minutes, the solution gradually turns blue; place in a water bath, heat to 80 ℃, the reaction time is 1.5h. 0.6g of catechin hydrate was added to the reaction solution, and ultrasonicated for 10 minutes, the solution changed from blue to dark gray; heated in a water bath at 80°C for 1 hour. Centrifuge the product, repeat washing and collection several times; then repeat washing with absolute ethanol, and store the obtained reduced graphene oxide-m...

Embodiment 3

[0046] Prepare 300mL of 20mol / mL NaOH solution, 30mL of 0.1mol / mL Cu(NO 3 ) 2 Solution, ultrasonically disperse graphene oxide in 20 mL of water with a concentration of 10 mg / mL. Put Cu(NO 3 ) 2 The solution was added to the graphene oxide aqueous solution, and the solution was changed from light blue to light brown by magnetic stirring for 35 minutes; 15mL of EDA was added and stirred for 20 minutes until the solution turned purple; the mixed solution was added to the solution containing NaOH (300mL, 15mol / mL ) In a three-necked flask, continue to stir for 10 minutes, the solution gradually turns blue; placed in a water bath, heated to 80 ℃, the reaction time is 2h. 0.6g of catechin hydrate was added to the reaction solution, ultrasonicated for 10 minutes, the solution changed from blue to dark gray; heated in a water bath at 80°C for 1.5 hours. Centrifuge the product, repeat washing and collection several times; then repeat washing with absolute ethanol, and store the obtaine...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com