Anoxic fluidized bed device for treating high-concentration nitrate-nitrogen wastewater

A waste water treatment and fluidized bed technology, applied in water treatment parameter control, biological water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of reduced effective utilization of reactors, unfavorable process operation, low filling rate, etc. problems, to achieve the effect of maintaining matrix mass transfer rate and wastewater treatment efficiency, improving air washing efficiency, and maintaining high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

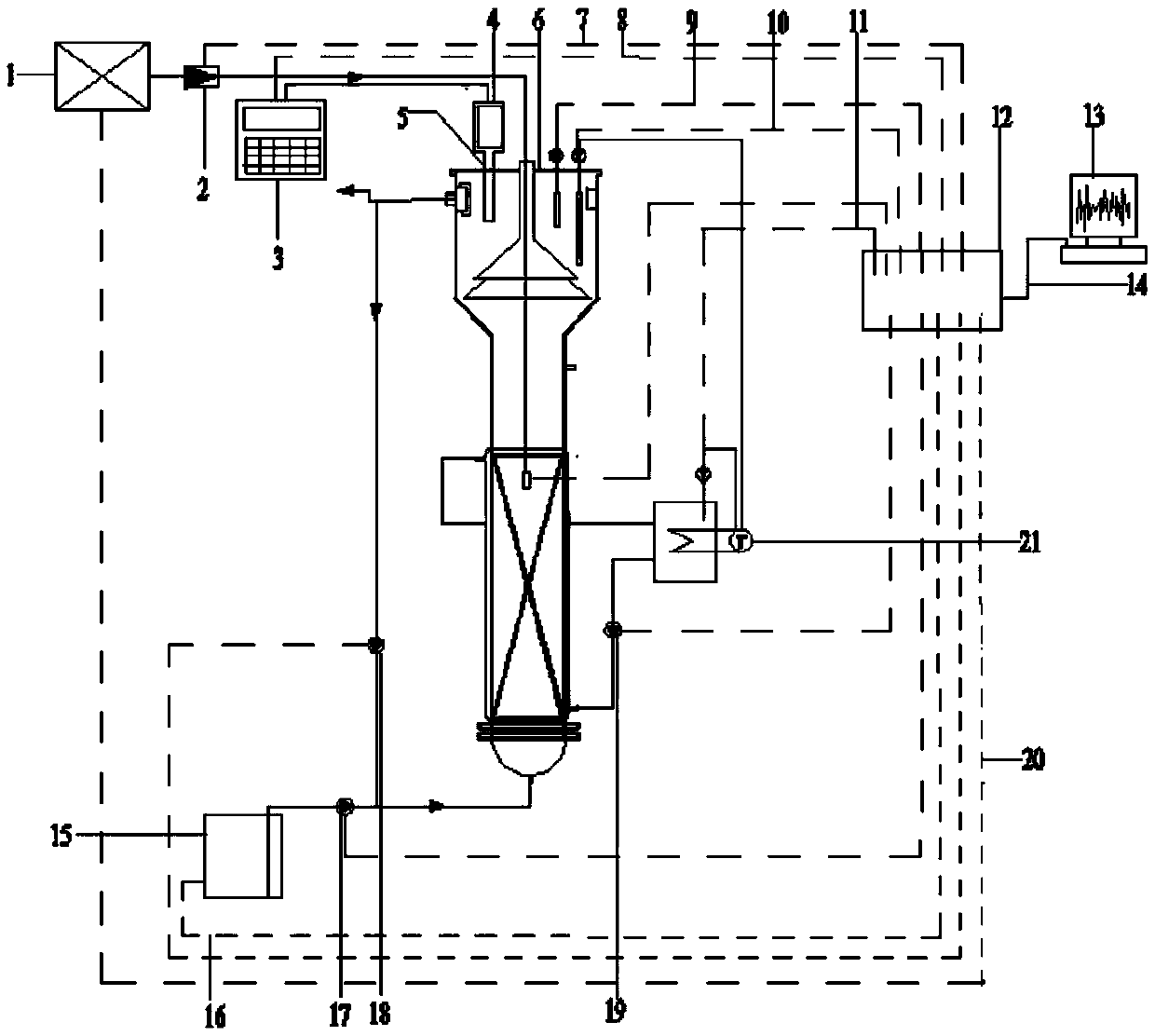

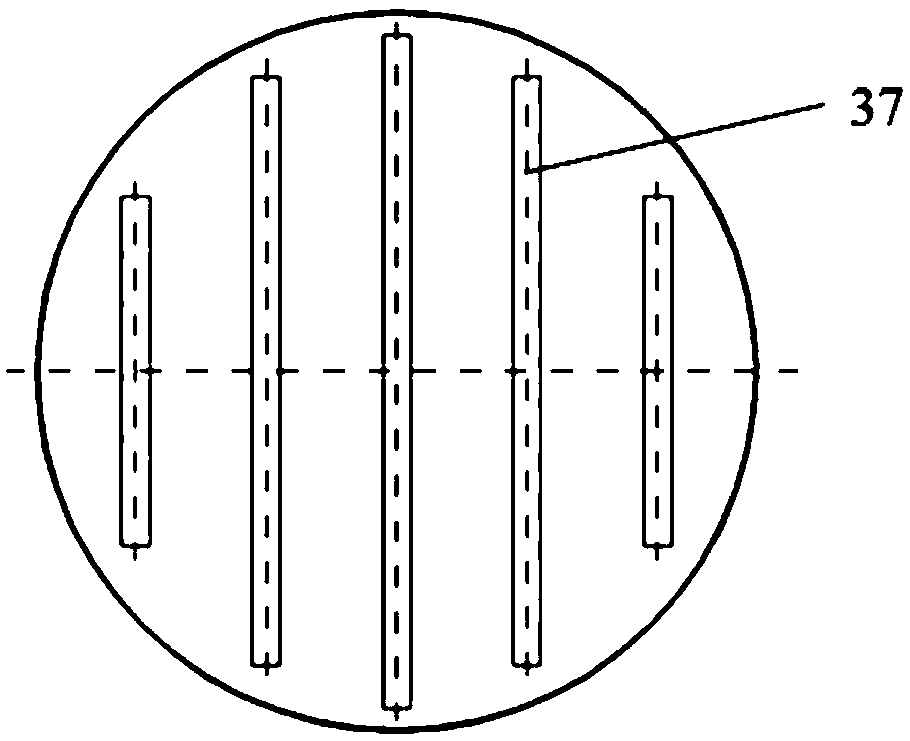

[0056] Such as figure 1 As shown, the anoxic fluidized bed device for the treatment of high-concentration nitrate-nitrogen wastewater of the present invention is a full-automatic nitrate-nitrogen wastewater treatment device composed of anoxic fluidized bed 6 and a computer monitoring system, and the anoxic fluidized bed The device consists of a feed tank 15, an anoxic fluidized bed 6, a nitrogen generator system 1, a nitrogen outlet distributor 35, an ultrasonic cleaning device, a heating device, a pH monitoring system, a temperature control system, a liquid level monitoring system, and a control data cabinet 12 constituted with a terminal controller 13,

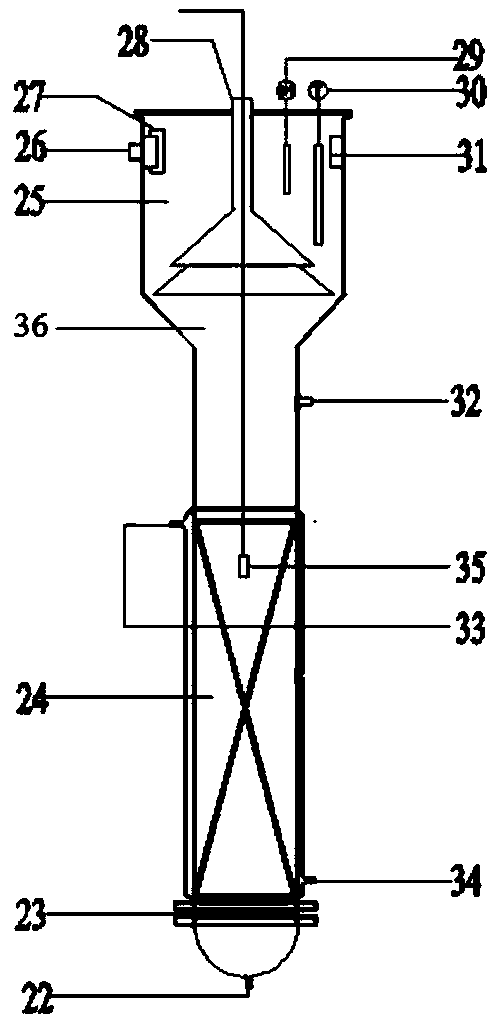

[0057] The anoxic fluidized bed is a cylindrical structure placed vertically, and can be made of steel plate, glass and other materials. The anoxic fluidized bed 6 comprises a packing area 24, a transition section 36, and a water outlet area 25 arranged successively from bottom to top, and a three-phase separator 28 is arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com