A kind of light-transmitting concrete body and preparation method thereof

A light-transmitting concrete and concrete technology, applied in the field of concrete materials, can solve the problems of lower overall strength of light-transmitting concrete body, increase of flexural/compressive strength, rapid aging of optical fiber surface, etc., to improve bonding performance and reduce water consumption , The effect of slowing down the aging of optical fiber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

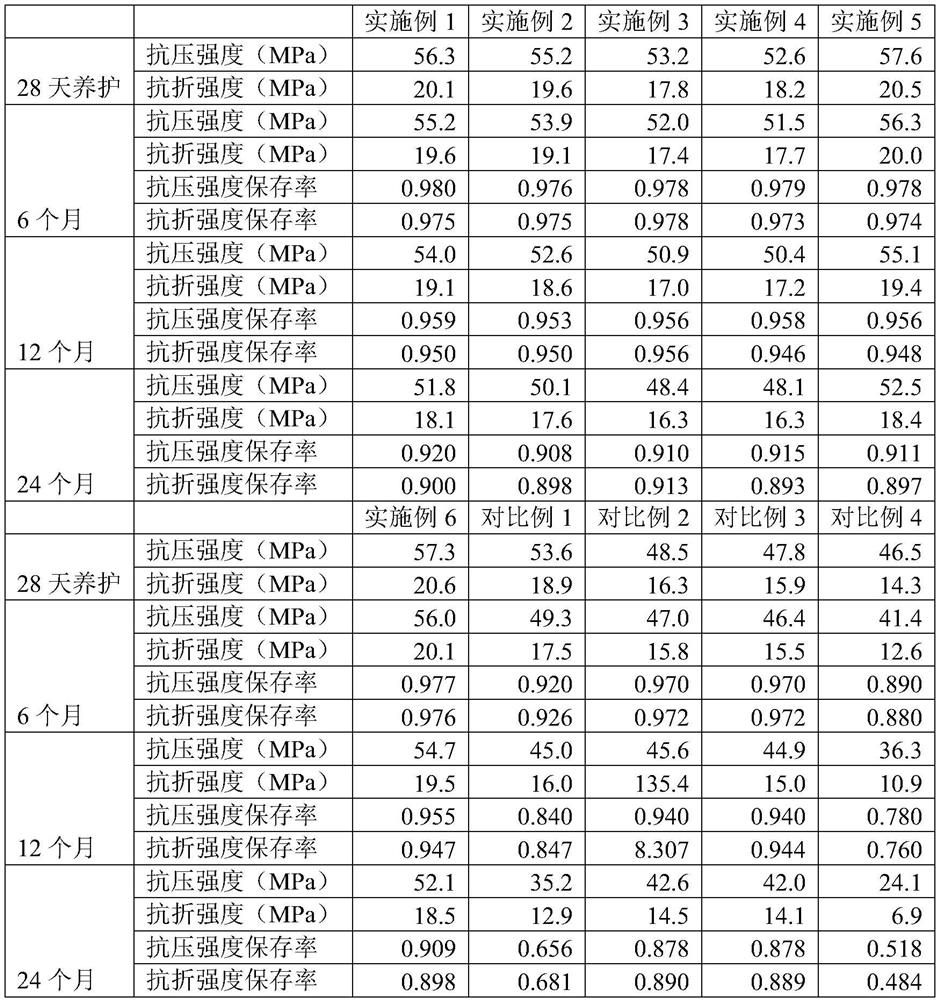

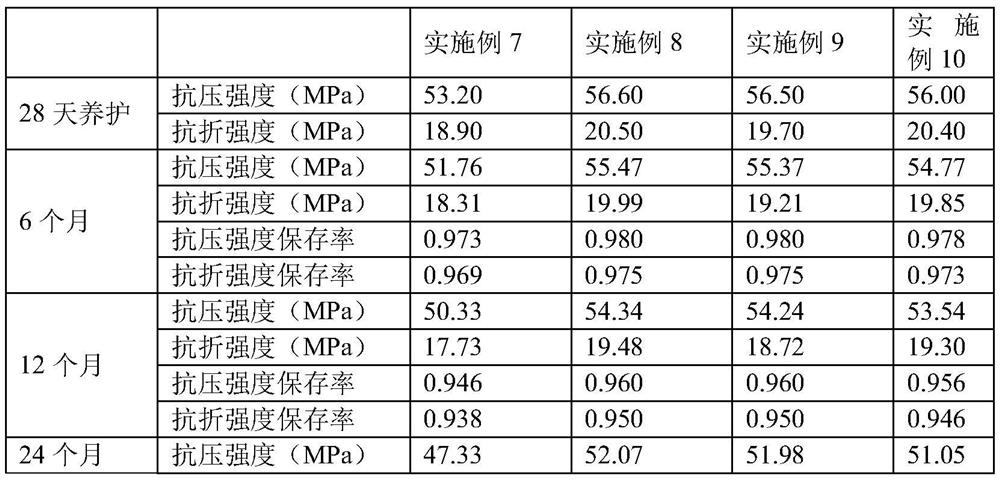

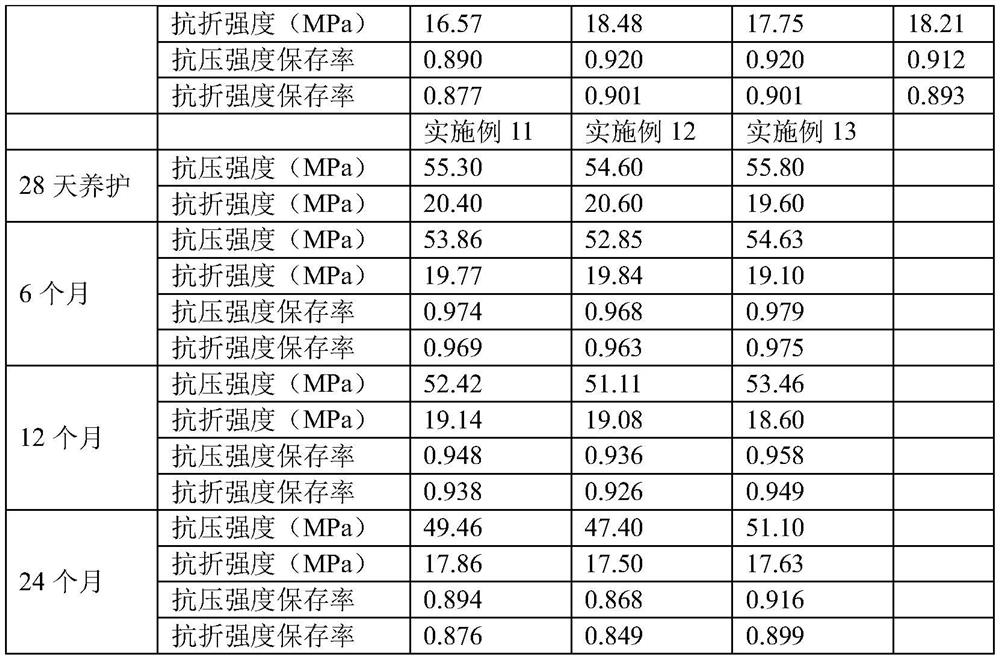

Examples

Embodiment 1

[0044] A light-transmitting concrete body is formed by embedding optical fibers in concrete and curing the concrete.

[0045] The added amount of optical fiber accounts for 5-20% of the volume of the light-transmitting concrete body.

[0046] Concrete is obtained by mixing raw materials mainly including the following parts by mass:

[0047] 400-429 parts of cement, using P.0.42.5;

[0048] 120-145 parts of water;

[0049] Sand 723-814 parts, using washed river sand with a fineness modulus of 2.3;

[0050] Aggregate 967-1089 parts, using crushed stone aggregate with a particle size of 10-30mm, using multi-stage compounding, in which the particle size is 10mm: 18mm: 30mm, the dosage-mass ratio is 5:3:1;

[0051] Lead slag powder 116-134 parts, fineness modulus 2.0;

[0052] 12-32 parts of sodium polyacrylate;

[0053] Zirconia calcined powder 165-197 parts, particle size 0.8±0.1mm.

[0054] The method for preparing the light-transmitting concrete body includes optical fibe...

Embodiment 7

[0084] A light-transmitting concrete body, which is based on Embodiment 1, the difference is that the optical fiber pretreatment is only processed to Y1, and the optical fiber split obtained by Y1 is fixed in the mold.

Embodiment 8

[0086] A light-transmitting concrete body, which is based on Embodiment 1, with the difference that the distance between the strands of optical fibers is adjusted so that the amount of optical fiber incorporated is 5% of the volume of the light-transmitting concrete body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com