Experimental device and method for studying the failure behavior of fuel elements under severe nuclear reactor accidents

A fuel element and nuclear reactor technology, which is used in nuclear reactor monitoring, reactors, nuclear engineering, etc., can solve problems such as inability to control internal pressure flexibly, and inability to study the effect of fuel element pellets, and achieve a wide range of research and comprehensive functions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in detail:

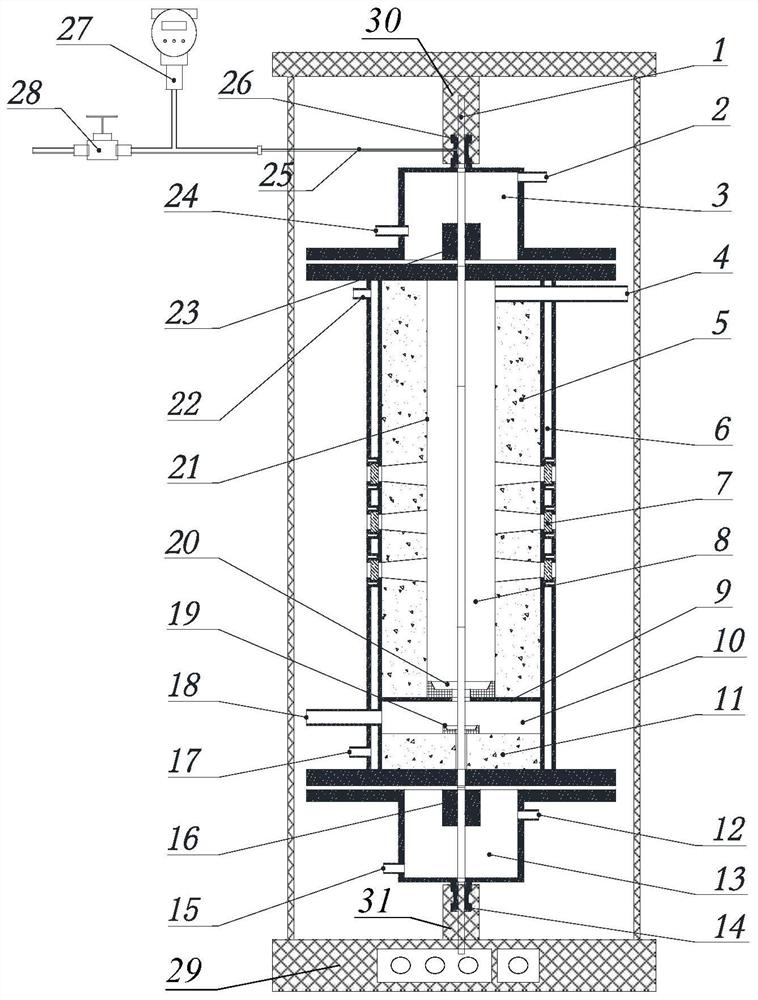

[0026] Such as figure 1 As shown, an experimental device for studying the failure behavior of fuel elements under severe nuclear reactor accidents includes an upper electrode cooling chamber 3 , a middle cylinder, a lower electrode cooling chamber 13 , a simulated fuel rod 1 and a tensile testing machine 29 .

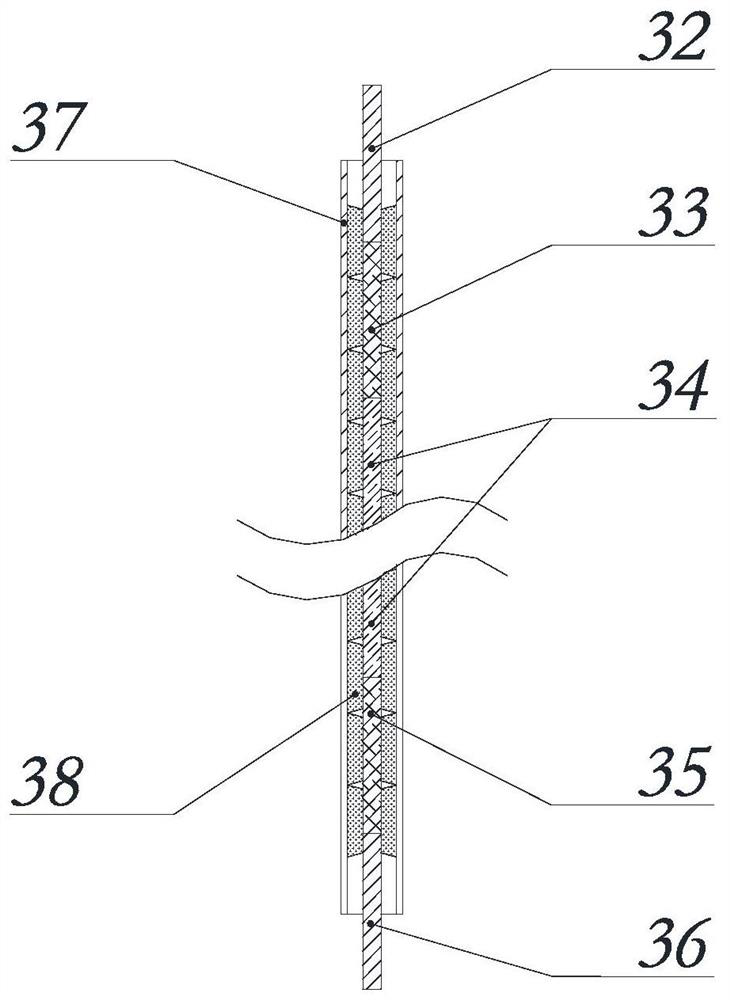

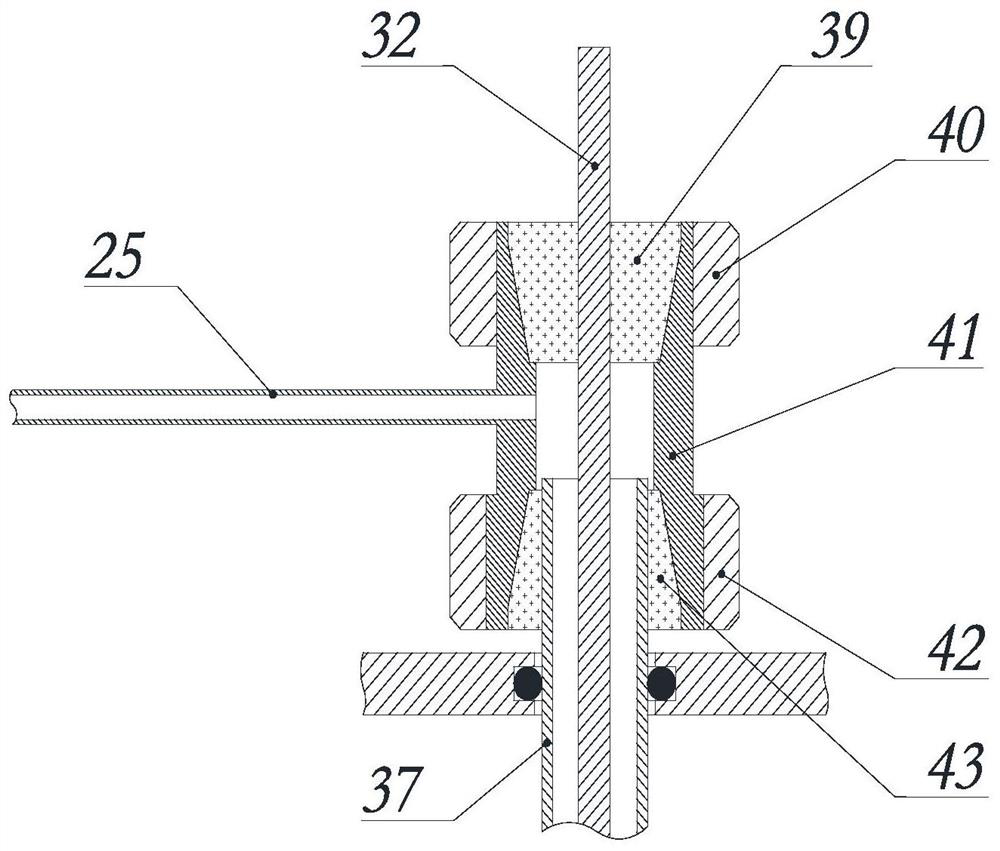

[0027] The simulated fuel rod 1 as figure 2 As shown, it consists of a heating rod, a ceramic core block 38 and a cladding 37; the heating rod includes a first copper electrode 32, a first molybdenum electrode 33, a tungsten rod 34, a second molybdenum electrode 35 and a second copper electrode connected in sequence by threads. Electrode 36; Copper has good thermal conductivity but has a low melting point. In the experiment, it needs to be continuously cooled by water, while molybdenum has a high melting point, which can extend into the middle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com