Method of applying engineering wastes as PRB packing to treatment of flow-out water of farmland

A technology for application engineering and waste, applied in the field of pollutants, can solve the problems of high cost and slow processing rate, and achieve the effects of convenient operation, simple installation and low environmental risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] The static adsorption method was used to study six kinds of materials, namely iron slag, limestone, corn straw biochar, magnesite slag, calcined magnesite slag and aluminum slag, to study their ability to remove nitrate nitrogen and total phosphorus. Prepare KH with pH=7, total ionic strength Ic=10mMol / L, Cp=50mg / L, CN=50mg / L 2 PO 4 -Na 2 HPO 4 and KNO 3 Mix the contaminated aqueous solutions and adjust the ionic strength with NaCl. Weigh 0.1g of each material and put it into a glass centrifuge tube with a volume of 50mL that has been added with 20mL nitrogen and phosphorus polluted aqueous solution, put it into a water bath thermostat shaker, control the temperature at 293K, and shake at a frequency of 150r / min. After 24 hours of adsorption, the supernatant was passed through a 0.45 μm filter membrane for determination. The results showed that calcined magnesite slag and iron slag had the strongest removal ability of phosphate, which were 688mg / kg and 384mg / kg res...

Embodiment 2

[0031] The method of static adsorption was used to study 6 kinds of materials, which were iron slag, limestone, corn straw biochar, magnesite slag, calcined magnesite slag and aluminum slag, and their effects on pesticides tricyclazole, rice blastling and malathion were studied. Phosphorus removal capacity. Prepare a total ionic strength Ic=10mMol / L mixed contaminated aqueous solution containing 1mg / L each of tricyclazole, rice blastin and malathion, and adjust the ionic strength with NaCl. Weigh 0.1g of each material and place it into a glass centrifuge tube with a volume of 50mL that has been added with 20mL of pesticide-contaminated aqueous solution, and shake it in a water-bath constant temperature oscillator. The temperature is controlled at 293K, and the shaking frequency is 150r / min. After 24 hours, the supernatant was taken and passed through a 0.22 μm filter membrane for determination. Straw biochar and iron slag have the strongest removal capacity for tricyclazole, ...

Embodiment 3

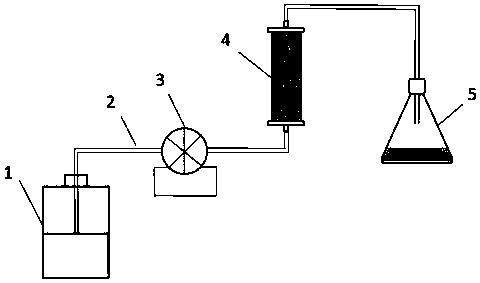

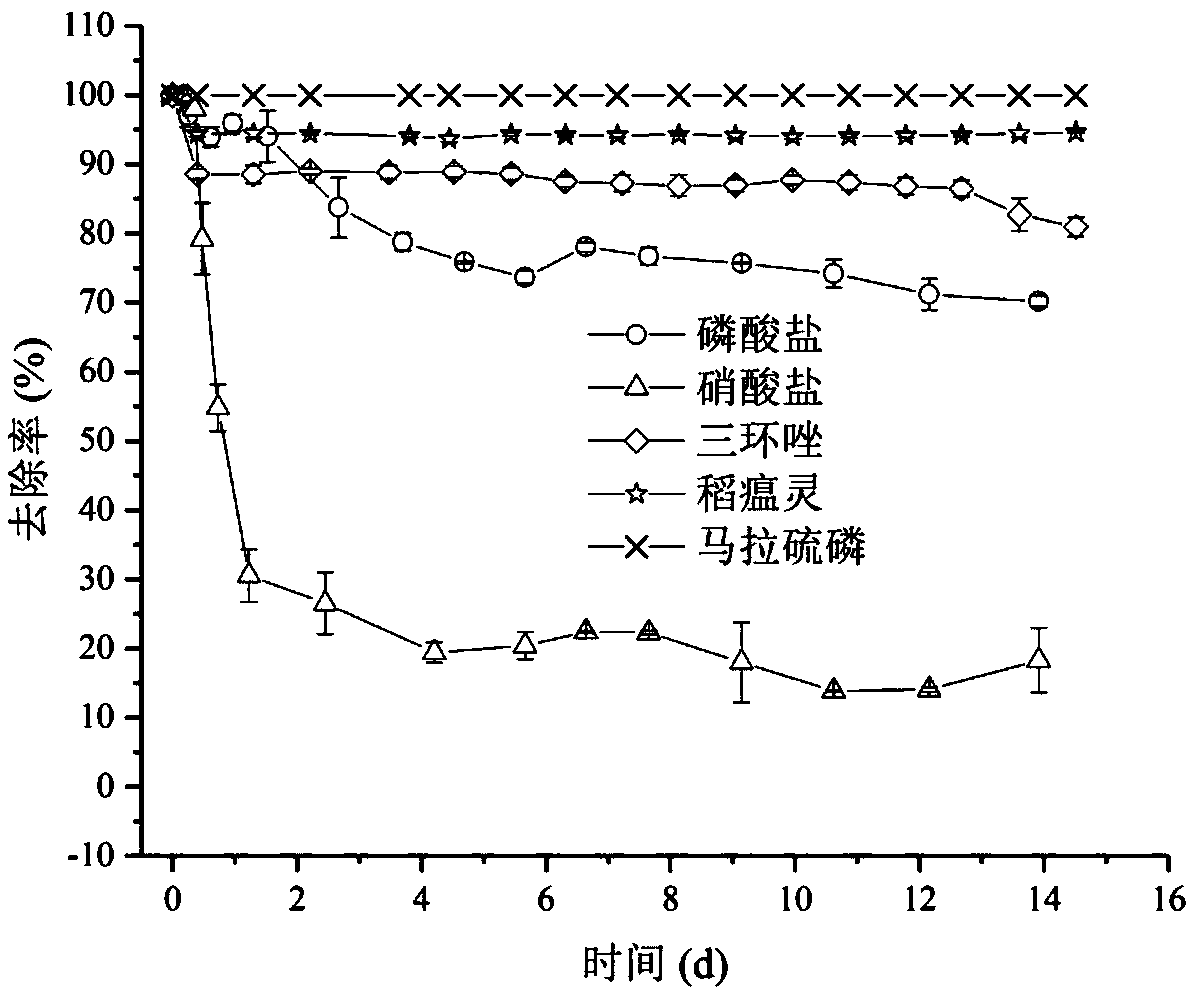

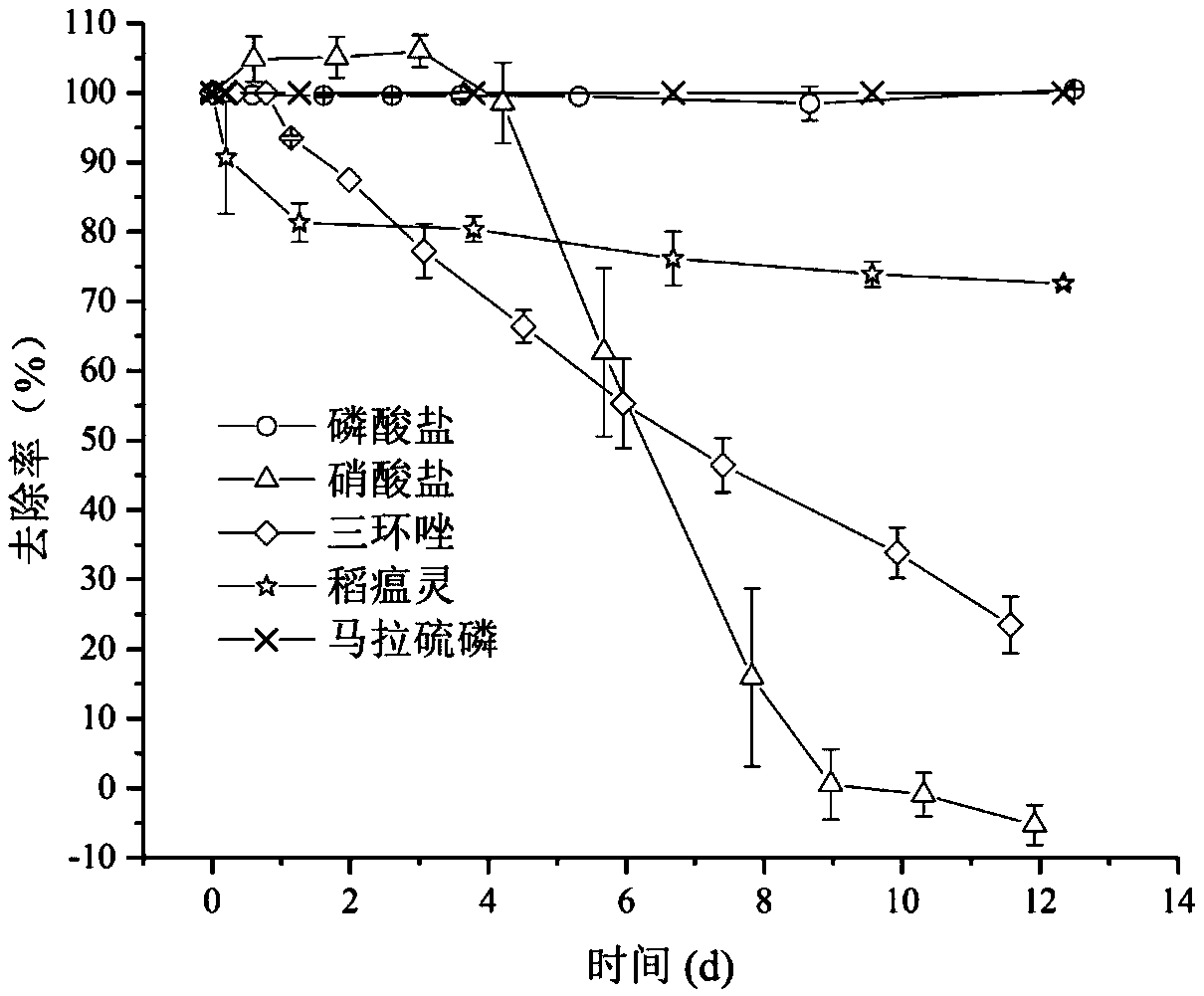

[0034]This embodiment selects a kind of engineering waste iron ore slag, that is, zero-valent iron filings are used as PRB fillers to treat waste water containing nitrogen, phosphorus and pesticides (30mg-N / L, 5mg-P / L, tricyclazole, rice blastling and Malathion each 1mg / L, pH 6.5-7, total ionic strength about 10mMol / L), according to the following steps: the quartz sand (purity 99.4%) with a particle size of 0.18-0.45mm is filled in the The inlet and outlet of the PRB device ensure that the contaminated solution passes through the PRB device evenly. Before filling, soak in 10mM NaOH and 10mM HCl for 6 hours to remove impurities, wash with ultrapure water until neutral, and then dry in an oven at 105°C. Screen the iron ore slag with a particle size of 0.42-0.84mm. Weigh a certain amount of iron slag and fill it in the middle 1 / 3 of the PRB device, weigh a certain amount of quartz sand and fill it in the upper and lower 1 / 3 positions, and the volume ratio of quartz sand to iron ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com