Preparation technology of microwave band metamaterial wave absorber

A technology of metamaterials and absorbers, which is applied in the direction of copying/marking methods, printing, electrical components, etc., can solve the problems of thin printing thickness and difficult control of conductivity, so as to improve the compactness and thickness, and improve the inkjet printing effect , the effect of improving conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0017] The invention provides a preparation method of a metamaterial absorber. The technical scheme provided by the invention is as follows:

[0018] Step 1: Use the commercialized (PMDA-ODA) type Kapton film PI film produced by DuPont Company of the United States, with a size of 180x180x0.05 (mm). Treat with potassium permanganate, potassium hydroxide, ethylenediamine and their mixture for 95 minutes, and dry in a drying oven at 500c for 5 minutes after cleaning.

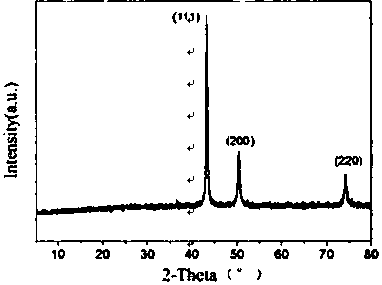

[0019] Step 2: First use AutoCAD drawing software to draw the optimized structure, and then use an inkjet printer to print on the modified PI film. The printing equipment used is an Epson ink tank integrated inkjet printer (Epson, L211, four-color), and the printing ink uses nano-silver conductive ink with a mass concentration of 10% (mass concentration is 10%), and the metamaterial obtained by inkjet printing Resonant unit pattern.

[0020] Step 3: Place the printed sample in a drying oven for heat treatment a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com