High-plasticity biodegradable Zn-2Li alloy under GPa-level high-pressure effect and preparation method thereof

A technology of zn-2li and high plasticity, applied in the field of high plasticity biodegradable Zn-2Li alloy and its preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

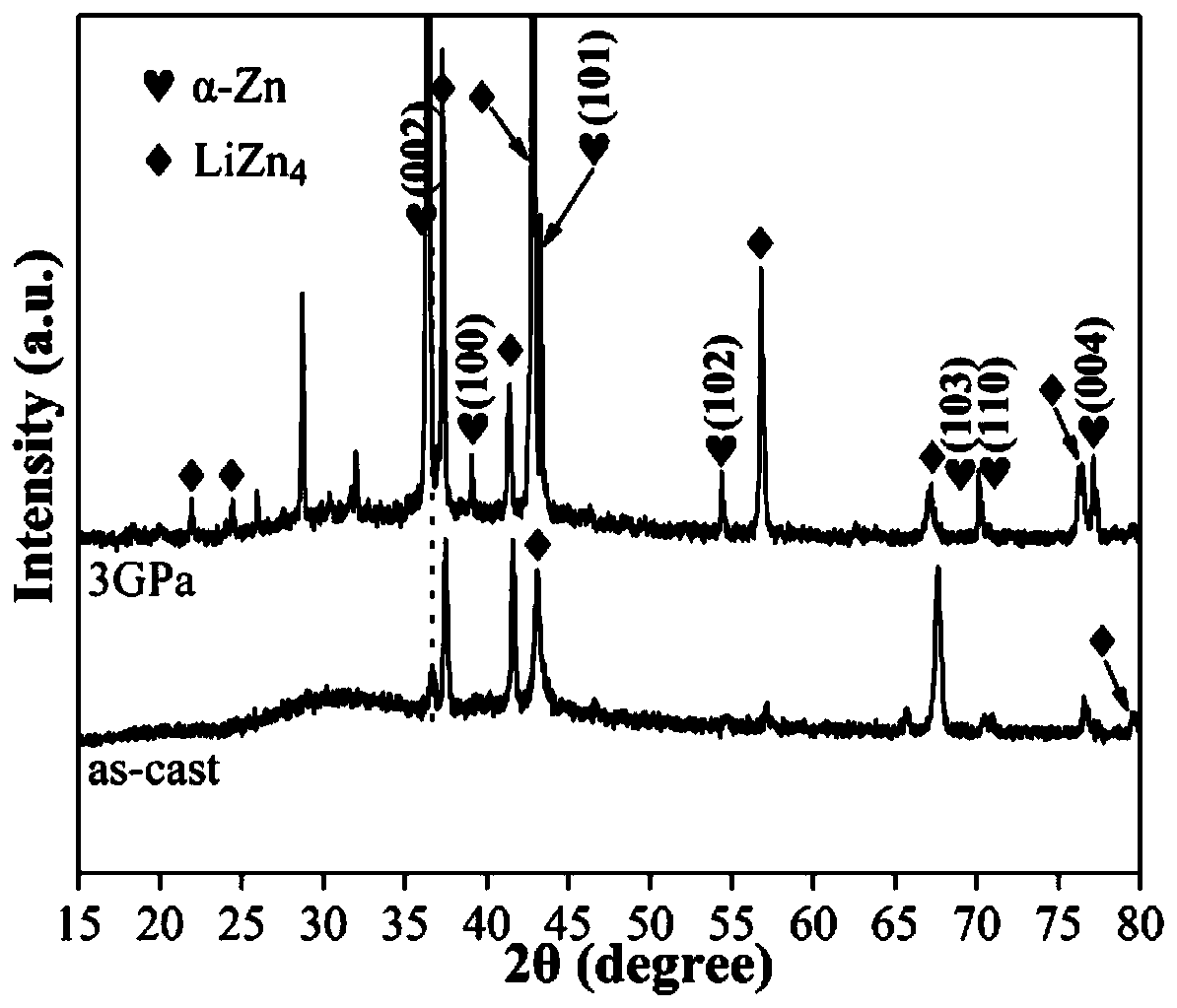

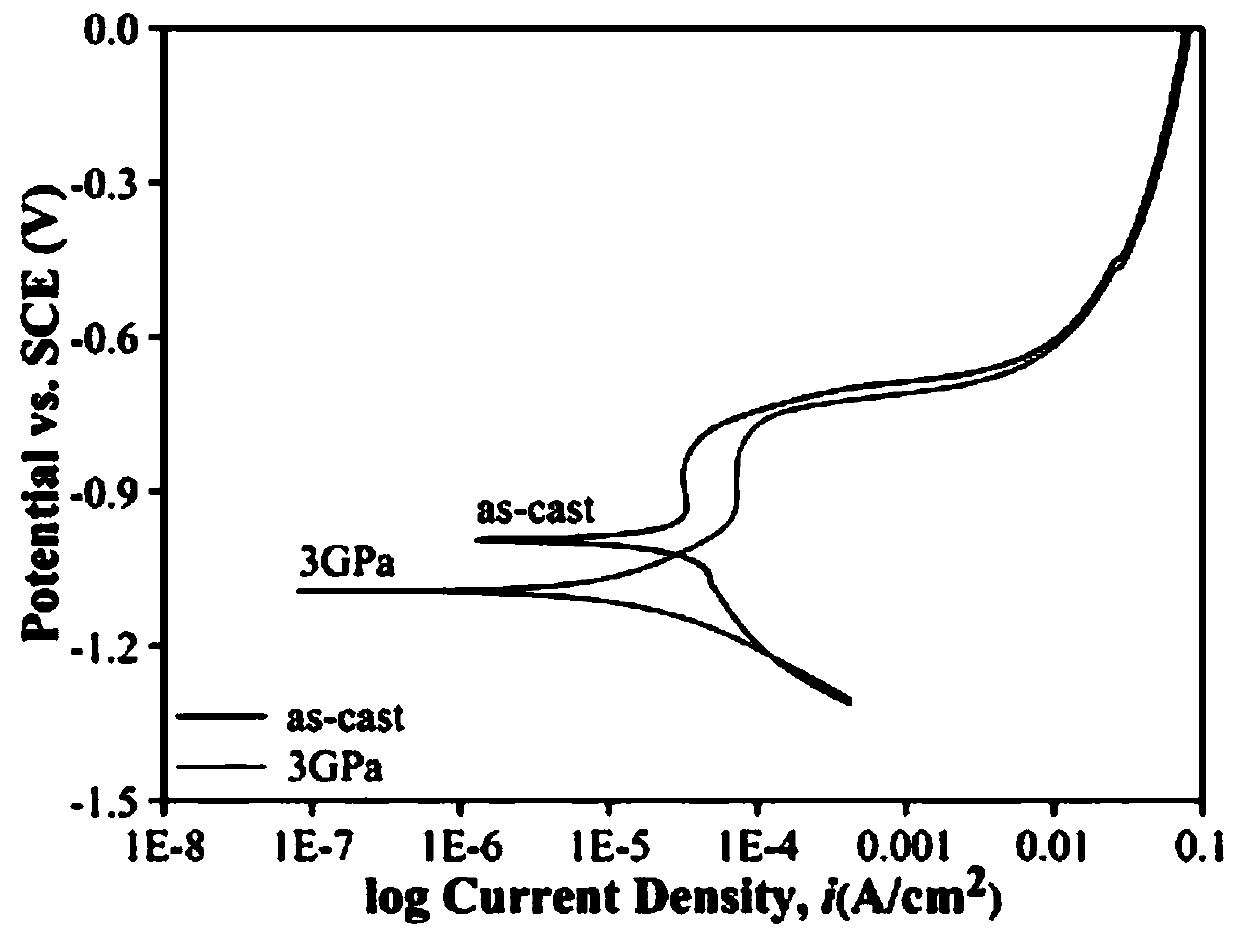

Examples

Embodiment 2

[0037] Example 2, the Zn-2 (wt.%) Li ingot was kept at 350° C. for 10 h for homogenization annealing and then water-cooled, and a cylindrical sample with a diameter of 10 mm and a length of 15 mm was prepared by wire cutting. The CS-1B high-pressure six-sided top press produced by Zhengzhou Abrasive Grinding Research Institute Co., Ltd. was used for high-pressure experiments. The pressure is set at 5GPa, and the heating temperature is set at 700°C according to the Clausius-Clapeyren equation and the melting point of the Zn-2Li alloy. Put the cylindrical sample into boron nitride, graphite sleeve and pyrophyllite in turn to form an assembly sleeve, then put the assembly sleeve into the cavity of the high-pressure six-sided roof, and start the high-pressure solidification and heat treatment experiment after the hammer head is aligned. First increase the pressure to the preset pressure, and at the same time start the temperature measuring device and turn on the water cooling devi...

Embodiment 3

[0038] Example 3, the Zn-2 (wt.%) Li ingot was kept at 350° C. for 10 h for homogenization annealing and then water-cooled, and a cylindrical sample with a diameter of 10 mm and a length of 15 mm was prepared by wire cutting. The CS-1B high-pressure six-sided top press produced by Zhengzhou Abrasive Grinding Research Institute Co., Ltd. was used for high-pressure experiments. The pressure is set at 5GPa, and the heating temperature is set at 700°C according to the Clausius-Clapeyren equation and the melting point of the Zn-2Li alloy. Put the cylindrical sample into boron nitride, graphite sleeve and pyrophyllite in turn to form an assembly sleeve, then put the assembly sleeve into the cavity of the high-pressure six-sided roof, and start the high-pressure solidification and heat treatment experiment after the hammer head is aligned. First increase the pressure to the preset pressure, and at the same time start the temperature measuring device and turn on the water cooling devi...

Embodiment 4

[0039]Example 4, the Zn-2 (wt.%) Li ingot was kept at 350° C. for 12 hours for homogenization annealing and then water-cooled, and a cylindrical sample with a diameter of 10 mm and a length of 15 mm was prepared by wire cutting. The CS-1B high-pressure six-sided top press produced by Zhengzhou Abrasive Grinding Research Institute Co., Ltd. was used for high-pressure experiments. The pressure is set at 1GPa, and the heating temperature is set at 500°C according to the Clausius-Clapeyren equation and in combination with the melting point of the Zn-2Li alloy. Put the cylindrical sample into boron nitride, graphite sleeve and pyrophyllite in turn to form an assembly sleeve, then put the assembly sleeve into the cavity of the high-pressure six-sided roof, and start the high-pressure solidification and heat treatment experiment after the hammer head is aligned. First increase the pressure to the preset pressure, and at the same time start the temperature measuring device and turn on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness value | aaaaa | aaaaa |

| Yield ratio | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com