Organic transistor element, organic light emitting transistor element, and manufacturing method thereof

A technology for a light-emitting transistor and a manufacturing method, which is applied in the manufacture of semiconductor/solid-state devices, transistors, electrical components, etc., can solve problems such as difficulty in reproducing production components, difficulty in making CNT mesh source electrodes, and insufficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

[0077] [Experimental example 1] Operation characteristics of Gr-VOLET

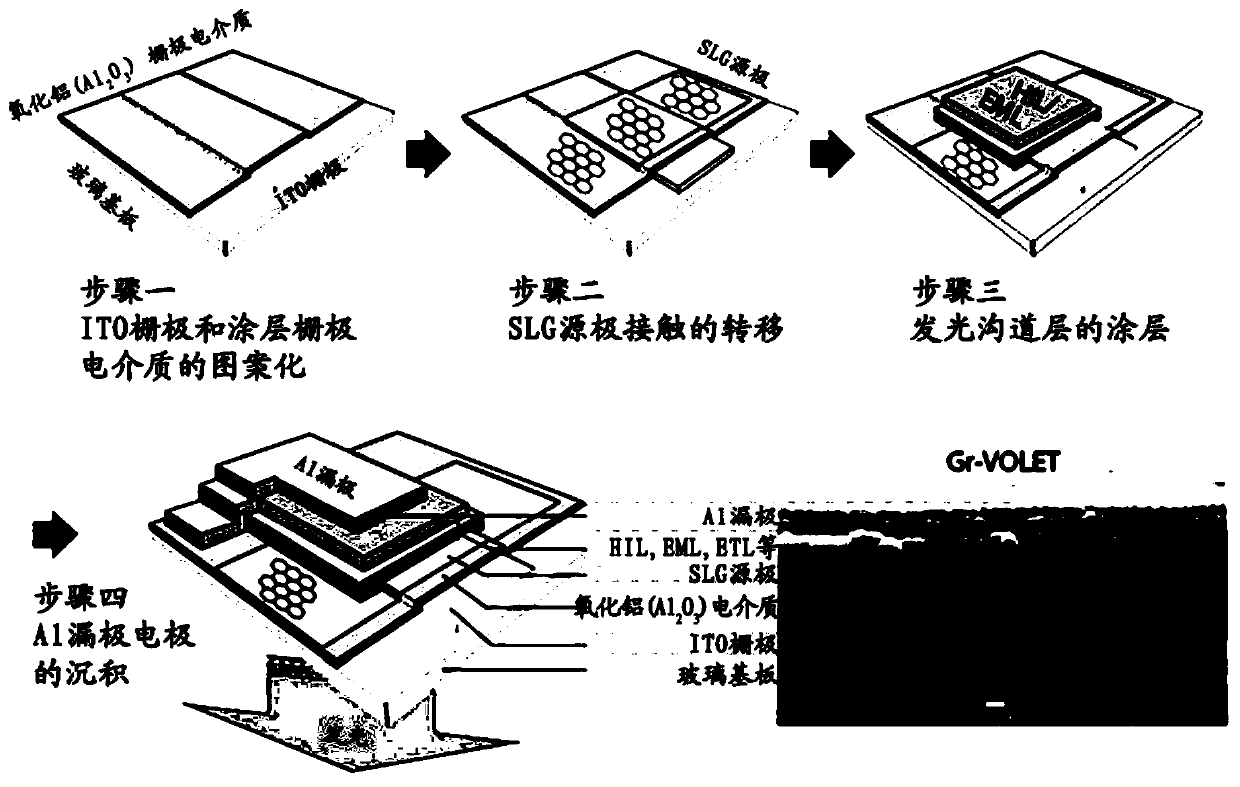

[0078] figure 1 is a diagram related to the structure of Gr-VOLETs, showing a bottom gate (Bottom-gate) including indium tin oxide (indium tin oxide, ITO), Al 2 o 3 Schematic structure of Gr-VOLET with gate dielectric layer, SLG source electrode, organic light-emitting channel layer, and Al metal drain electrode. By the action of Gr-VOLET, holes are injected from the SLG source to the light-emitting channel layer, and electrons are injected from the Al drain to the light-emitting channel layer. Through the action of Gr-VOLET, hole injection from the source of SLG can be performed by applying gate voltage, V GS (or V G ) for modulation, V G The application essentially affects the electroluminescence process that takes place in the channel layer.

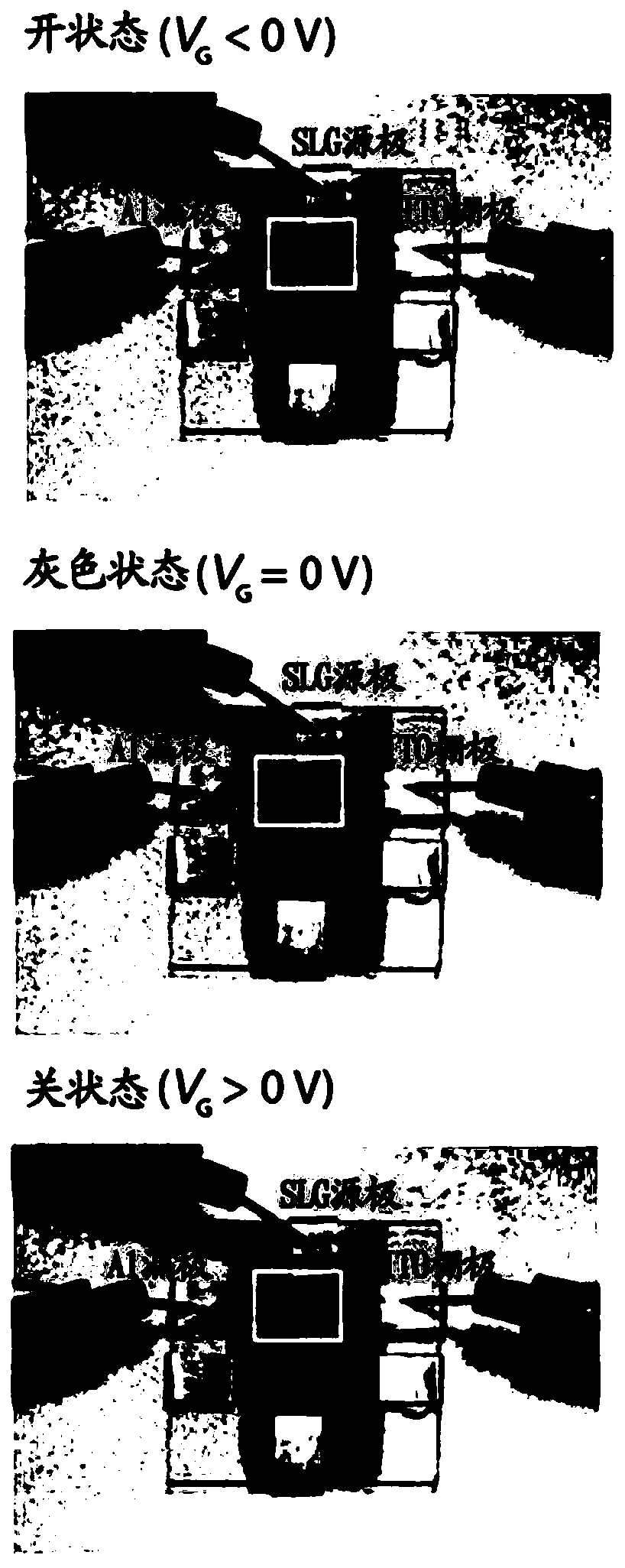

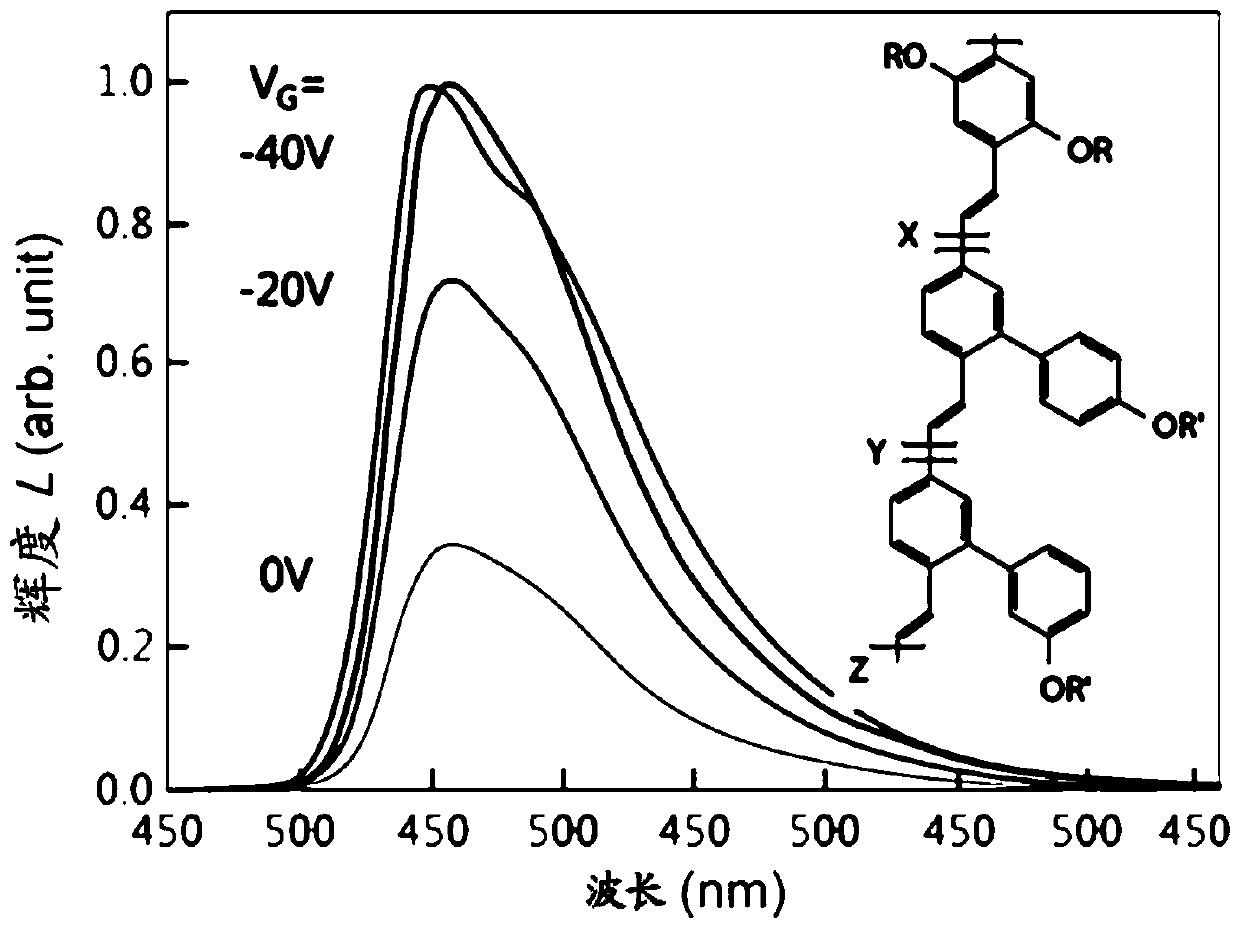

[0079] figure 2 shown at a fixed source-drain voltage of -3.8V (V DS ) (or V SD =3.8V), at various V G EL light emission of the Gr-VOLET sample under a...

Embodiment 1

[0083] SLG with intrinsic characteristics cleaned by electron chemistry (hereinafter referred to as "SLG 1 ")

Embodiment 2

[0085] With ferric chloride (FeCl 3 ) p-type doped SLG (hereinafter referred to as "SLG 2 ")

PUM

| Property | Measurement | Unit |

|---|---|---|

| Current density | aaaaa | aaaaa |

| Roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com