Wheat germ biscuit and processing technology thereof

A technology of wheat germ and wheat germ powder, which is applied in the direction of pre-baked dough processing, baking, baked food with modified ingredients, etc., and can solve the problems of inability to release wheat germ nutrients, poor stickiness of wheat germ powder, and affecting the hardness of biscuits, etc. problems, to achieve the effect of rich taste and flavor, improve health care function, and improve the degree of crispness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

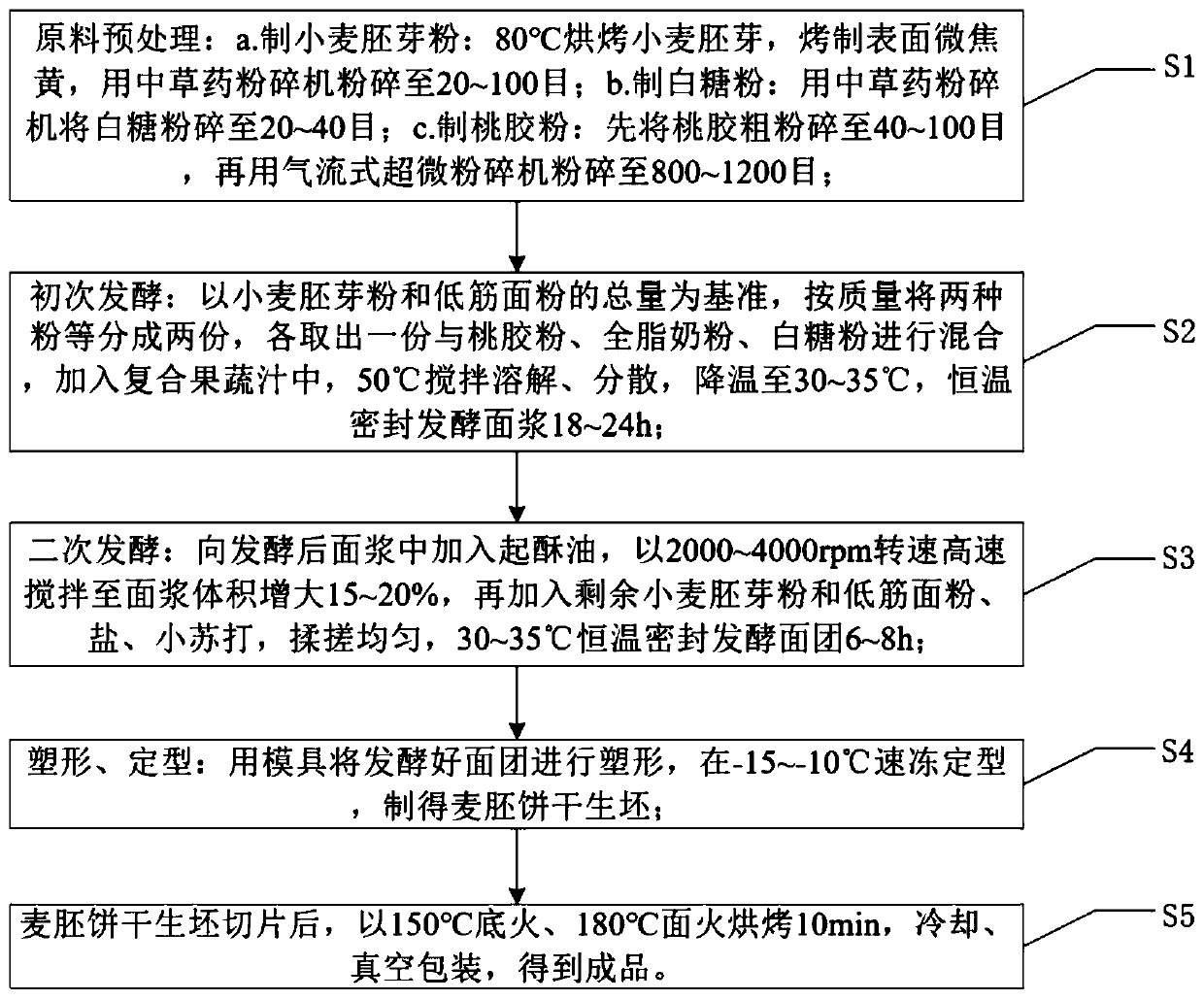

[0027] A processing technology of wheat germ biscuits, comprising the following steps:

[0028] S1: Raw material pretreatment and preparation:

[0029] a. Preparation of wheat germ powder: bake the wheat germ at 80°C, bake the surface slightly browned, and grind it to 20 meshes with a Chinese herbal medicine grinder;

[0030] b. Preparation of white sugar powder: grind the white sugar to 20 mesh with a Chinese herbal medicine grinder;

[0031] c. Making peach gum powder: first coarsely pulverize the peach gum to 40 mesh, and then crush it to 800 mesh with an air-flow ultrafine pulverizer;

[0032] d. Making compound fruit and vegetable juice: mix and squeeze pineapple, dragon fruit, blueberry, cucumber, and water according to the mass ratio of 3:3:1:4:100;

[0033] e. Preparation of fermented probiotics: mix Saccharomyces cerevisiae, Lactobacillus casei, Lactobacillus plantarum, and Lactobacillus Brucella in a mass ratio of 5:1:1.5:1.5;

[0034] f. Weigh and prepare materia...

Embodiment 2

[0040] A processing technology of wheat germ biscuits, comprising the following steps:

[0041] S1: Raw material pretreatment and preparation:

[0042] a. Preparation of wheat germ powder: bake the wheat germ at 80°C until the surface is slightly browned, and pulverize it to 60 meshes with a Chinese herbal medicine grinder;

[0043] b. Preparation of white sugar powder: grind the white sugar to 30 mesh with a Chinese herbal medicine grinder;

[0044] c. Making peach gum powder: first coarsely pulverize the peach gum to 70 mesh, and then crush it to 1000 mesh with an airflow ultrafine pulverizer;

[0045] d. Making compound fruit and vegetable juice: mix and squeeze pineapple, dragon fruit, blueberry, cucumber and water according to the mass ratio of 4:4:1.5:5:100;

[0046] e. Preparation of fermented probiotics: mix Saccharomyces cerevisiae, Lactobacillus casei, Lactobacillus plantarum, and Lactobacillus Brucella in a mass ratio of 5:1.2:1.8:1.8;

[0047] f. Weigh and prepare...

Embodiment 3

[0053] A processing technology of wheat germ biscuits, comprising the following steps:

[0054] S1: Raw material pretreatment and preparation:

[0055] a. Preparation of wheat germ powder: bake the wheat germ at 80°C, the roasted surface is slightly browned, and crush it to 100 meshes with a Chinese herbal medicine grinder;

[0056] b. Preparation of white sugar powder: grind the white sugar to 40 mesh with a Chinese herbal medicine grinder;

[0057] c. Making peach gum powder: first coarsely pulverize the peach gum to 100 mesh, and then crush it to 1200 mesh with an airflow ultrafine pulverizer;

[0058] d. Making compound fruit and vegetable juice: mix pineapple, dragon fruit, blueberry, cucumber, and water according to the mass ratio of 5:5:2:6:100;

[0059] e. Preparation of fermented probiotics: mix Saccharomyces cerevisiae, Lactobacillus casei, Lactobacillus plantarum, and Lactobacillus Brucella in a mass ratio of 5:1.5:2:2;

[0060] f. Weigh and prepare materials acc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com