Thermal-shock-resistant environment-friendly domestic ceramic product and preparation method thereof

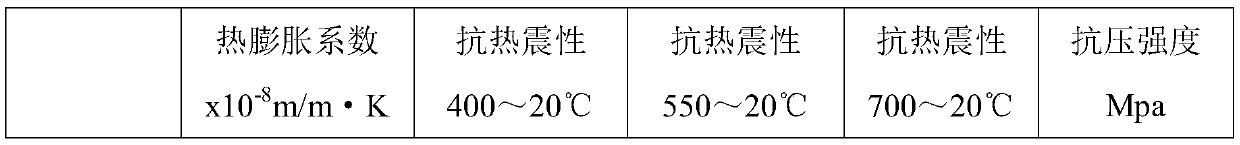

A technology for ceramic products and thermal shock resistance, applied in the field of ceramic products, can solve the problems of poor appearance strength and other comprehensive properties, high thermal expansion coefficient, poor thermal shock resistance, etc., to save glazing process, good mechanical properties, thermal resistance Good shock performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] A heat-shock-resistant and environment-friendly ceramic product for daily use is made of the following raw materials in parts by weight:

[0054] Mullite powder 100~125 parts,

[0055] Lithium porcelain stone powder 20-27 parts,

[0056] Lithium feldspar powder 12-17 parts,

[0057] Attapulgite clay 30-36 parts,

[0058] Silica fiber 45~60 parts,

[0059] 20-30 parts of silicon-aluminum-magnesium high-strength fiber.

[0060] Preferably, the heat-shock-resistant and environmentally-friendly daily-use ceramic products are made of raw materials including the following parts by weight:

[0061] Mullite powder 105~120 parts,

[0062] Lithium porcelain stone powder 21~25 parts,

[0063] Lithium feldspar powder 14~16 parts,

[0064] Attapulgite clay 32-35 parts,

[0065] Silica fiber 48~55 parts,

[0066] Si-Al-Mg high-strength fiber 24-28 parts.

[0067] Preferably, the heat-shock-resistant and environmentally-friendly daily-use ceramic products are made of raw mat...

Embodiment 2

[0085] A heat-shock-resistant and environment-friendly ceramic product for daily use is made of the following raw materials in parts by weight:

[0086] Mullite powder 105 parts,

[0087] Lithium porcelain stone powder 21 parts,

[0088] Lithium feldspar powder 14 parts,

[0089] Attapulgite clay 32 parts,

[0090] Silica fiber 48 parts,

[0091] 24 parts of silicon-aluminum-magnesium high-strength fiber.

[0092] In this embodiment, the mullite powder is zircon mullite powder.

[0093] In this embodiment, the particle size of the mullite powder, hectorite powder and hectorite powder is all 3000 mesh.

[0094] In this embodiment, the particle size of the attapulgite clay is 5000 mesh.

[0095] In this embodiment, the preparation method of the thermal shock-resistant environmental protection daily-use ceramic products includes the following steps:

[0096] A, by weight, take respectively mullite powder, lithium china stone powder, lithium feldspar powder, attapulgite cla...

Embodiment 3

[0103] A heat-shock-resistant and environment-friendly ceramic product for daily use is made of the following raw materials in parts by weight:

[0104] Mullite powder 120 parts,

[0105] Lithium porcelain stone powder 25 parts,

[0106] Lithium feldspar powder 16 parts,

[0107] Attapulgite clay 35 parts,

[0108] Silica fiber 55 parts,

[0109] 28 parts of silicon-aluminum-magnesium high-strength fiber.

[0110] In this embodiment, the mullite powder is zircon mullite powder.

[0111] In this embodiment, the particle size of the mullite powder, hectorite powder and hectorite powder is all 3000 mesh.

[0112] In this embodiment, the particle size of the attapulgite clay is 5000 mesh.

[0113] In this embodiment, the preparation method of the thermal shock-resistant environmental protection daily-use ceramic products includes the following steps:

[0114] A, by weight, take respectively mullite powder, lithium china stone powder, lithium feldspar powder, attapulgite cla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com