High-impedance film and preparation method thereof

A high-impedance, sputtering technology, applied in metal material coating process, vacuum evaporation plating, coating, etc., can solve the problems of poor anti-interference effect, small surface resistance, poor anti-static effect, etc., to improve clarity Harmony, good anti-interference effect, good anti-static effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A method for preparing a high-impedance film, the method comprising the steps of:

[0020] The magnetron sputtering method is used to coat the glass substrate, the target used is an indium tin oxide ceramic target, and the pressure of the sputtering chamber is pumped to 1.5×10 -3 Pa, the working gas is argon, the concentration of argon is 99.99%, the sputtering pressure is 0.3Pa, the sputtering time is 2min, the sputtering power is 40W, the sputtering distance is 8cm, and the sputtering method is DC sputtering.

Embodiment 2

[0022] A method for preparing a high-impedance film, the method comprising the steps of:

[0023] The magnetron sputtering method is used to coat the glass substrate, the target material used is an indium tin oxide ceramic target, and the pressure of the sputtering chamber is pumped to 2×10 -3 Pa, the working gas is argon, the concentration of argon is 99.99%, the sputtering pressure is 0.6Pa, the sputtering time is 7min, the sputtering power is 80W, the sputtering distance is 8cm, and the sputtering method is DC sputtering.

Embodiment 3

[0025] A method for preparing a high-impedance film, the method comprising the steps of:

[0026] The magnetron sputtering method is used to coat the glass substrate, the target used is an indium tin oxide ceramic target, and the pressure of the sputtering chamber is pumped to 3×10 -3 Pa, the working gas is argon, the concentration of argon is 99.99%, the sputtering pressure is 1.0Pa, the sputtering time is 10min, the sputtering power is 100W, the sputtering distance is 8cm, and the sputtering method is DC sputtering.

[0027] The square resistance of the high resistance film that embodiment 1-3 makes is 10 8 -10 10 Europe.

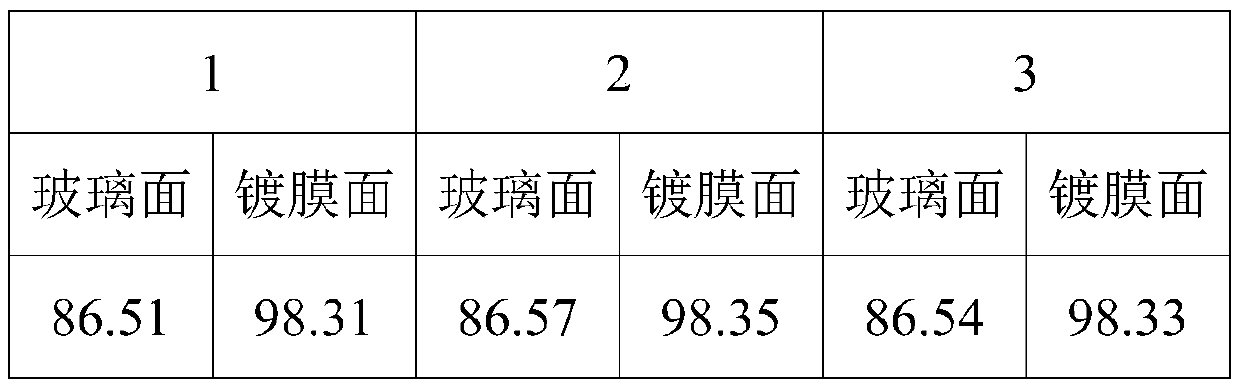

[0028] Take three pieces of 5cm×5cm coated glass prepared in Examples 1-3 respectively, and measure the transmittance values before and after the coated glass under sunlight and the square resistance values, as shown in Table 1-Table 3.

[0029] Table 1 embodiment 1 makes the transmittance of coated glass

[0030]

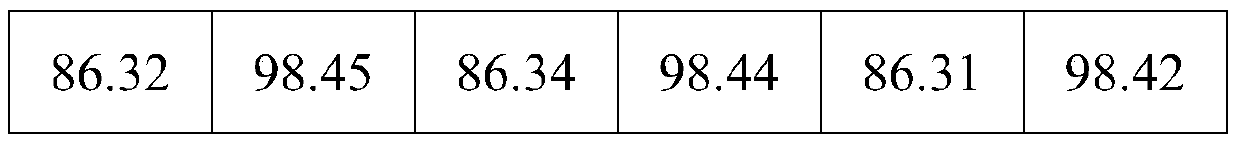

[0031] Table 2 embodiment 1 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com