High-heat-conductivity, oxygen-resistance, scale-prevention and wear-resistance composite pipe

A composite pipe, high thermal conductivity technology, applied in the direction of pipeline damage/abrasion prevention, pipe, rigid pipe, etc., can solve the problems of easy wear of the outer wall, increase the quality of the pipe material, and complicated preparation process, so as to achieve good anti-corrosion and improve heat conduction efficiency , easy to prepare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

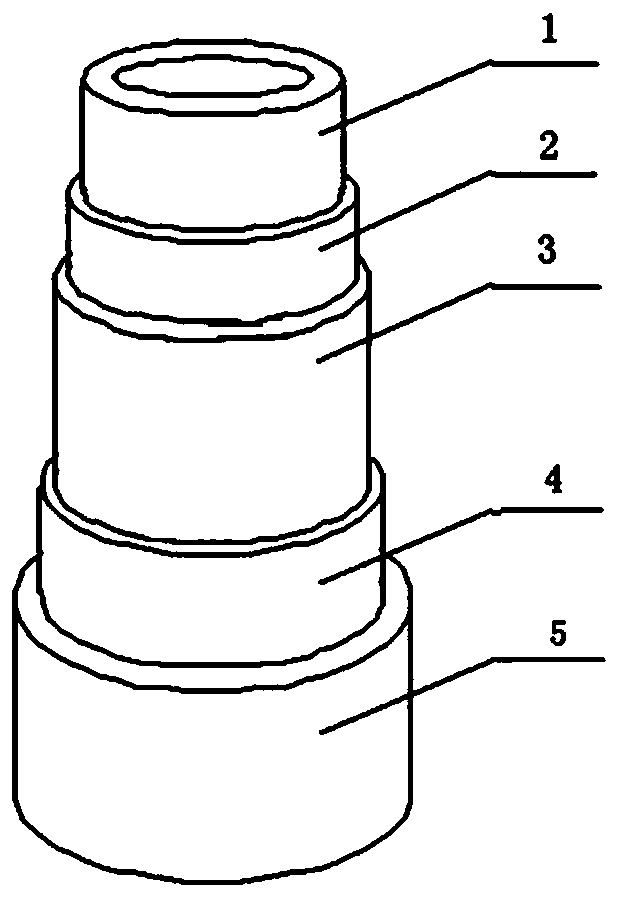

[0020] An embodiment of the high thermal conductivity, oxygen resistance, anti-scaling and wear-resistant composite pipe of the present invention, the outer diameter of the high thermal conductivity and oxygen resistance, anti-scaling and wear-resistant composite pipe is 20 mm, and the structural diagram is as follows figure 1 As shown, it has a 5-layer structure. From the inside to the outside, there are PE inner pipe anti-fouling layer 1, first hot melt adhesive layer 2, EVOH oxygen barrier layer 3, second hot melt adhesive layer 4 and PE outer pipe with high thermal conductivity. The wear-resistant layer 5, wherein the anti-fouling layer 1 of the PE inner pipe has a thickness of 0.2mm, is made of the following materials in parts by weight: 100 parts of polyethylene, 2 parts of heptadecanefluorodecyltrimethoxysilane; the first hot melt adhesive The thickness of layer 2 and the second hot-melt adhesive layer 4 are both 0.1mm, and the preparation materials are all EVA150; the t...

Embodiment 2

[0022] An embodiment of the high thermal conductivity, oxygen resistance, anti-scaling and wear-resistant composite pipe of the present invention, the outer diameter of the high thermal conductivity and oxygen resistance, anti-scaling and wear-resistant composite pipe is 20 mm, and the structural diagram is as follows figure 1 As shown, it has a 5-layer structure. From the inside to the outside, there are PE inner pipe anti-fouling layer 1, first hot melt adhesive layer 2, EVOH oxygen barrier layer 3, second hot melt adhesive layer 4 and PE outer pipe with high thermal conductivity. The wear-resistant layer 5, wherein the anti-fouling layer 1 of the PE inner pipe has a thickness of 0.2mm, is made of the following materials in parts by weight: 100 parts of polyethylene, 4 parts of heptadecanefluorodecyltrimethoxysilane; the first hot melt adhesive The thickness of layer 2 and the second hot-melt adhesive layer 4 are both 0.1mm, and the preparation materials are all EVA150; the t...

Embodiment 3

[0024] An embodiment of the high thermal conductivity, oxygen resistance, anti-scaling and wear-resistant composite pipe of the present invention, the outer diameter of the high thermal conductivity and oxygen resistance, anti-scaling and wear-resistant composite pipe is 20 mm, and the structural diagram is as follows figure 1 As shown, it has a 5-layer structure. From the inside to the outside, there are PE inner pipe anti-fouling layer 1, first hot melt adhesive layer 2, EVOH oxygen barrier layer 3, second hot melt adhesive layer 4 and PE outer pipe with high thermal conductivity. The wear-resistant layer 5, wherein the anti-scale layer 1 of the PE inner pipe has a thickness of 0.2mm, is made of the following materials in parts by weight: 100 parts of polyethylene, 5 parts of heptadecanefluorodecyltrimethoxysilane; the first hot melt adhesive The thickness of layer 2 and the second hot-melt adhesive layer 4 are both 0.1mm, and the preparation materials are all EVA150; the thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap