Low-profile wide-angle scanning all-metal multi-beam lens antenna

A technology of wide-angle scanning and lens antennas, which is applied in leaky waveguide antennas, antennas, antenna arrays, etc., can solve the problems of increased strength, high antenna overall section, difficult engineering and practical application of antennas, etc., and achieves miniaturized structure and good focusing performance , the effect of simplifying the section height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] specific implementation plan

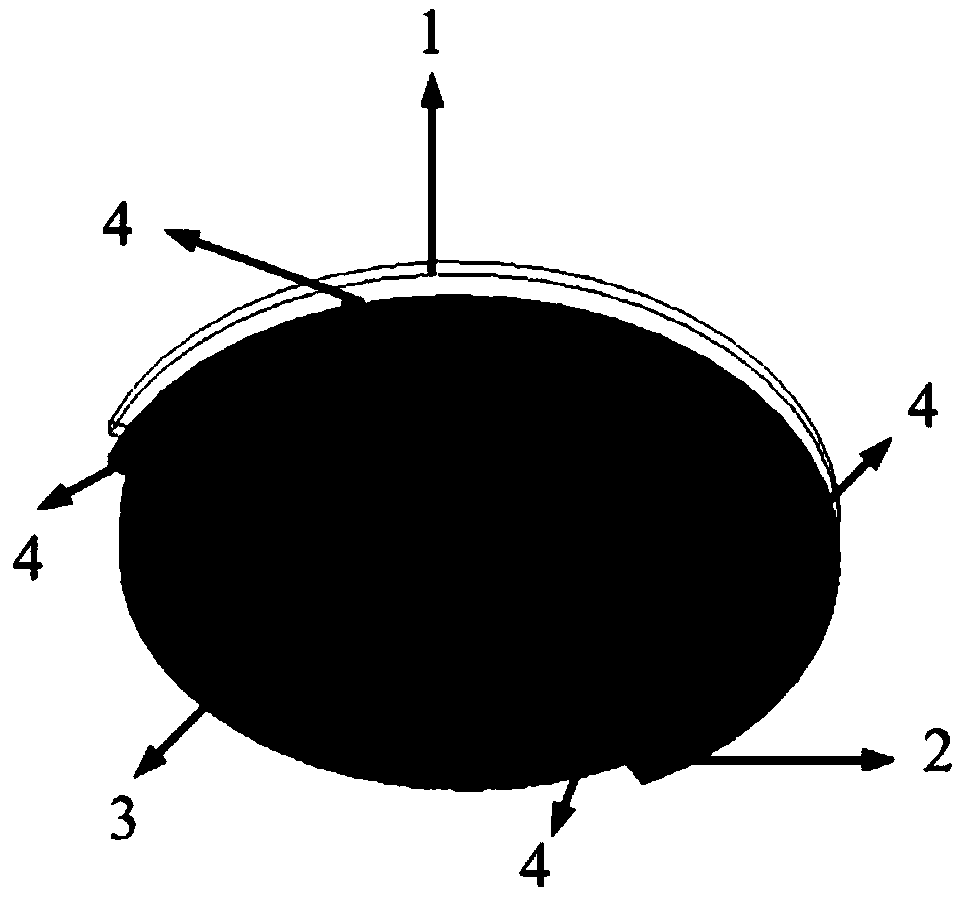

[0016] figure 1 , figure 2 , image 3 and Figure 4 The design structure diagram of the all-metal multi-beam lens antenna with low profile and wide-angle scanning is described in detail. According to the illustration, this device mainly includes the upper layer 1 of the metal parallel plate, the lower layer 2 of the metal parallel plate, and the arc array 3 composed of 18 microstrip feed antennas in the all-metal lens antenna, which are used to fix the upper layer 1 and the lower layer of the metal parallel plate. The metal screw 4 of the lower layer 2 of the metal parallel plate. The maximum aperture size of the lens antenna is 122×5mm 2 , the focal length of the feed source from the lens is 5mm, and the distance between the metal parallel upper layer 1 and the metal parallel plate lower layer 2 is selected as 1.5mm, which is much smaller than the wavelength at the design center frequency of 28GHz. Common lens antenna feeds are mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com