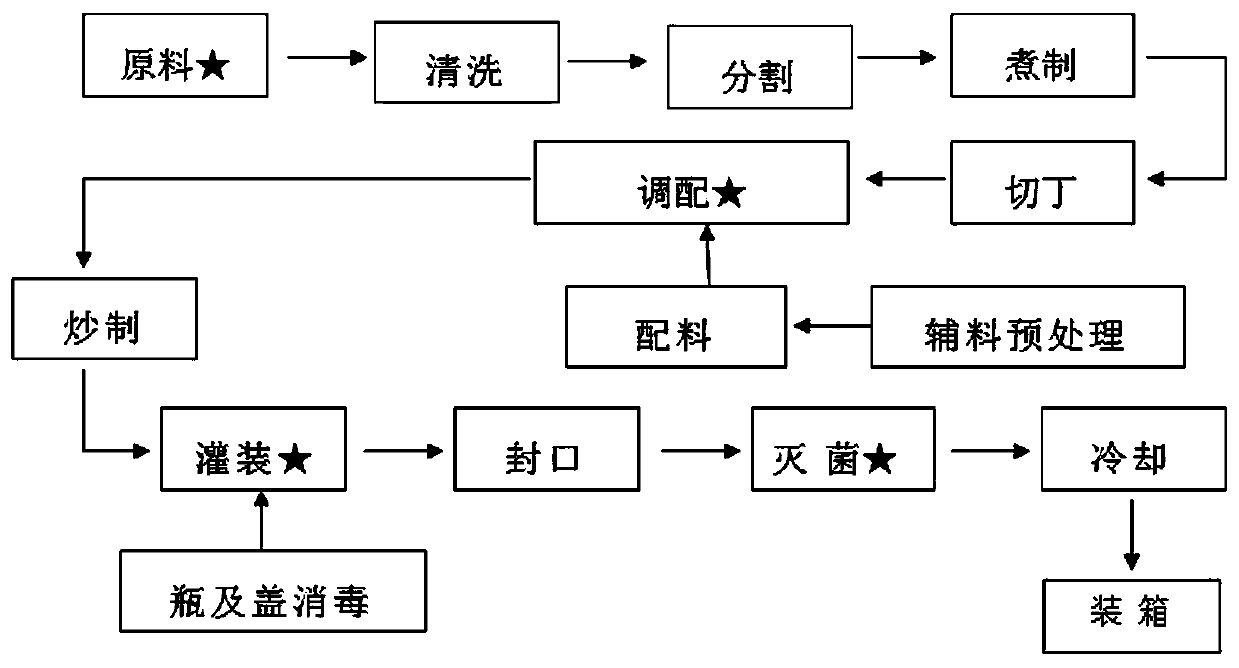

Production technology of cattle meat paste

A production process, the technology of beef paste, which is applied in the field of food processing, can solve the problems of lack of nutrition and health, heavy taste, etc., and achieve the effect of better taste, strong and durable, and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

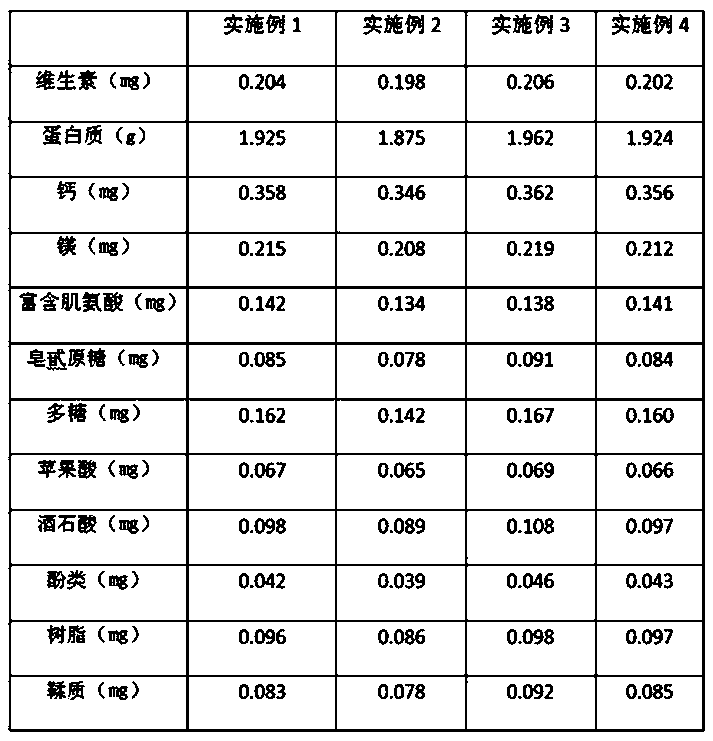

Examples

Embodiment 1

[0029] 1. Acceptance of raw materials: The raw and auxiliary materials used should meet the corresponding national standards, industry standards or enterprise standards after filing; meat must provide quarantine and epidemic prevention certificates, and if it is a product that is subject to production license management, it must be used to obtain a production license Qualified products produced by the enterprise, the beef chooses Nanyang Yellow Beef;

[0030] 2. Cleaning: Clean the beef in a stainless steel double sink;

[0031] 3. Segmentation: Use a stainless steel knife to remove tendons and membranes from the cleaned beef, divide the large pieces of meat into small pieces of 1-1.5 kg, and transfer them to the cooking room;

[0032] 4. Cooking: In the cooking room, use a stainless steel cooking barrel to cook the divided beef for 60 minutes, and the cooking temperature is above 100°C;

[0033] 5. Diced: Use a dicing machine to cut the cooked beef into cubes of about 1cm fo...

Embodiment 2

[0045]1. Acceptance of raw materials: The raw and auxiliary materials used should meet the corresponding national standards, industry standards or enterprise standards after filing; meat must provide quarantine and epidemic prevention certificates, and if it is a product that is subject to production license management, it must be used to obtain a production license Qualified products produced by the enterprise, the beef chooses Nanyang Yellow Beef;

[0046] 2. Cleaning: Clean the beef in a stainless steel double sink;

[0047] 3. Segmentation: Use a stainless steel knife to remove tendons and membranes from the cleaned beef, divide the large pieces of meat into small pieces of 1-1.5 kg, and transfer them to the cooking room;

[0048] 4. Cooking: In the cooking room, use a stainless steel cooking barrel to cook the divided beef for 60 minutes, and the cooking temperature is above 100°C;

[0049] 5. Diced: Use a dicing machine to cut the cooked beef into cubes of about 1cm for...

Embodiment 3

[0061] 1. Acceptance of raw materials: The raw and auxiliary materials used should meet the corresponding national standards, industry standards or enterprise standards after filing; meat must provide quarantine and epidemic prevention certificates, and if it is a product that is subject to production license management, it must be used to obtain a production license Qualified products produced by the enterprise, the beef chooses Nanyang Yellow Beef;

[0062] 2. Cleaning: Clean the beef in a stainless steel double sink;

[0063] 3. Segmentation: Use a stainless steel knife to remove tendons and membranes from the cleaned beef, divide the large pieces of meat into small pieces of 1-1.5 kg, and transfer them to the cooking room;

[0064] 4. Cooking: In the cooking room, use a stainless steel cooking barrel to cook the divided beef for 60 minutes, and the cooking temperature is above 100°C;

[0065] 5. Diced: Use a dicing machine to cut the cooked beef into cubes of about 1cm fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com