Spirulina culture solution for culture machine

A technology of spirulina and culture solution, which is applied in the direction of microorganisms, bacteria, biochemical equipment and methods, etc., can solve the problems of not being able to satisfy the growth of spirulina, achieve the effects of fast growth rate of spirulina, prolong the cultivation period, and reduce the dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

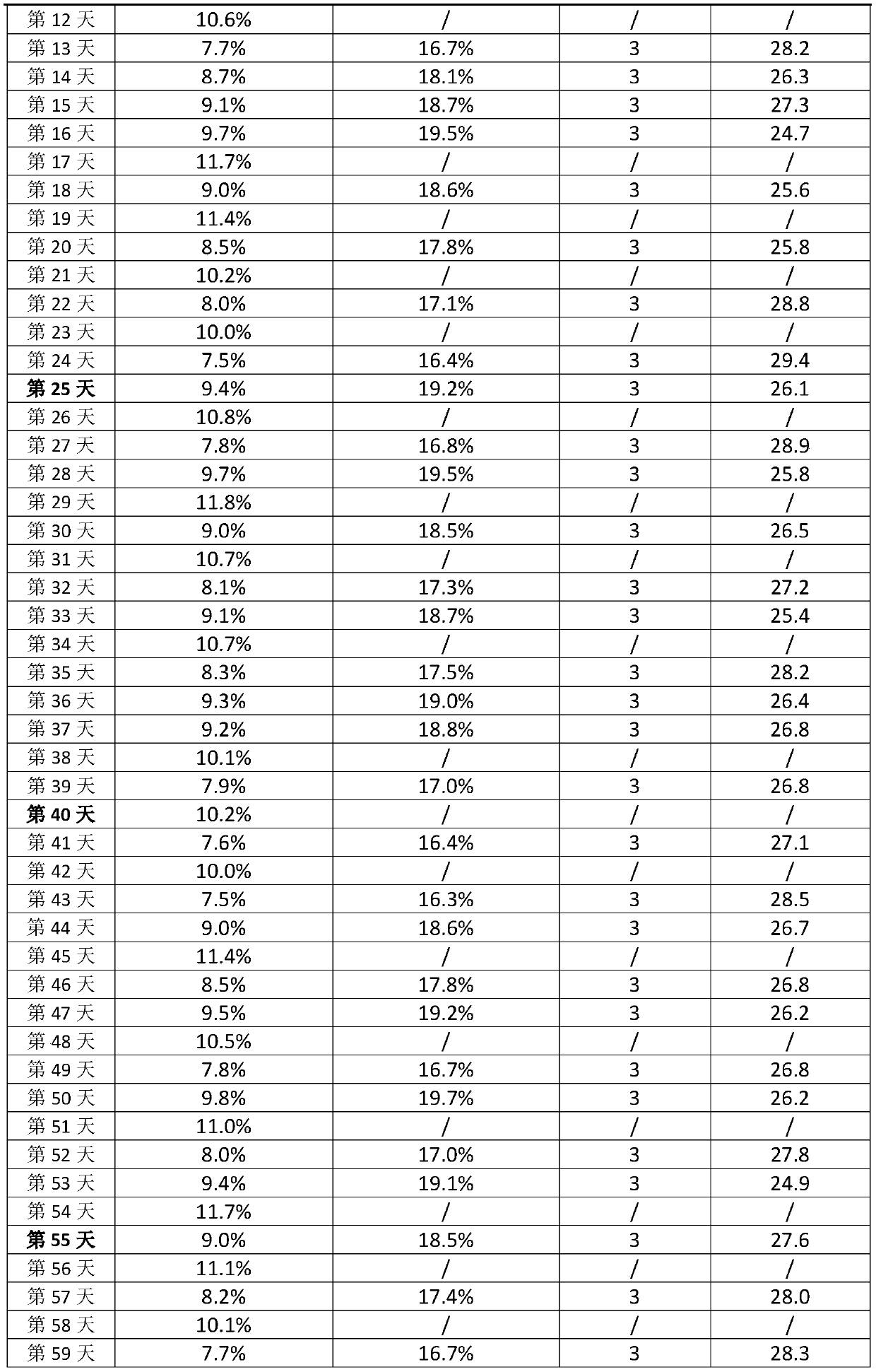

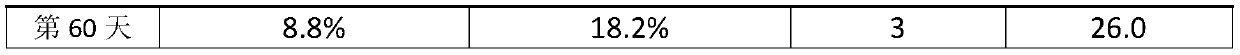

Examples

Embodiment 1

[0018] (1) Measure 10L of distilled water and place it in the culture machine;

[0019] (2) by FeSO 4 ·7H 2 O-0.1g, EDTA-0.4g, CaCl 2 2H 2 O-0.2g, MgSO 4 ·7H 2 O-2g, NaCl-2g, K 2 SO 4 -5g, KNO 3 -20g, K 2 HPO 4 -5g, NaHCO 3 - 100g is dissolved in water one by one, stirring and / or blowing while putting in, each time after the previous component is dissolved, then put in the next component, and so on, until all the components are dissolved ;

[0020] (3) Add 25g of Spirulina algae species to the culture medium formed in (2), and then use an air pump to agitate the culture medium, light for 10 hours a day, the light intensity is about 50μmol / (㎡·S), and the temperature is controlled at 25 degrees Celsius ;

[0021] (4) Check the pH value, when the pH value is between 10-12, press H 3 BO 3 -20g, MnCl 2 4H 2 O-15g, ZnSO 4 ·7H 2 O-2g, CuSO 4 ·5H 2 O-0.4g, Mo 7 o 24 6(NH 4 )·4H 2 O-0.1g, Co(NO 3 ) 2 ·6H 2 O-40mg order to add trace element supplement solutio...

Embodiment 2

[0024] (1) Measure 10L of distilled water and place it in the culture machine;

[0025] (2) by FeSO 4 ·7H 2 O-0.1g, EDTA-0.4g, CaCl 2 2H 2 O-0.3g, MgSO 4 ·7H 2 O-3g, NaCl-2g, K 2 SO 4 -5g, KNO 3 -25g, K 2 HPO 4 -6g, NaHCO 3 - 120g is dissolved in water one by one, stirring and / or blowing while adding, each time after the previous component is dissolved, then put in the next component, and so on, until all the components are dissolved ;

[0026] (3) Add 25g of Spirulina algae species to the culture solution formed in (2), then use an air pump to agitate the culture solution, light for 10 hours a day, the light intensity is about 50μmol / (㎡ S), and the temperature is controlled at 25 degrees Celsius;

[0027] (4) Check the pH value, when the pH value is between 10-12, press H 3 BO 3 -25g, MnCl 2 4H 2 O-20g, ZnSO 4 ·7H 2 O-3g, CuSO 4 ·5H 2 O-0.5g, Mo 7 o 24 6(NH 4 )·4H 2 O-0.15g, Co(NO 3 ) 2 ·6H 2 O-45mg order to add trace element supplements;

[0028]...

Embodiment 3

[0030] (1) Measure 10L of distilled water and place it in the culture machine;

[0031] (2) by FeSO 4 ·7H 2 O-0.2g, EDTA-0.5g, CaCl 2 2H 2 O-0.4g, MgSO 4 ·7H 2 O-4g, NaCl-3g, K 2 SO 4 -6g, KNO 3 -30g, K 2 HPO 4 -8g, NaHCO 3 - 130g is dissolved in water one by one, stirring and / or blowing while adding, each time after the previous component is dissolved, then put in the next component, and so on, until all the components are dissolved ;

[0032] (3) Add 25g of Spirulina algae species to the culture solution formed in (2), then use an air pump to agitate the culture solution, light for 10 hours a day, the light intensity is about 50μmol / (㎡ S), and the temperature is controlled at 25 degrees Celsius;

[0033] (4) Check the pH value, when the pH value is between 10-12, press H 3 BO 3 -30g, MnCl 2 4H 2 O-25g, ZnSO 4 ·7H 2 O-4g, CuSO 4 ·5H 2 O-0.6g, Mo 7 o 24 6(NH 4 )·4H 2 O-0.2g, Co(NO 3 ) 2 ·6H 2 0-50mg sequence of adding trace element supplements;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com