Preparation method of flaky iron phosphate dihydrate

A technology of phosphoric acid dihydrate, iron phosphate, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as unfavorable industrial production and application, complex synthesis process, etc., and achieve the effects of good electrochemical performance and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

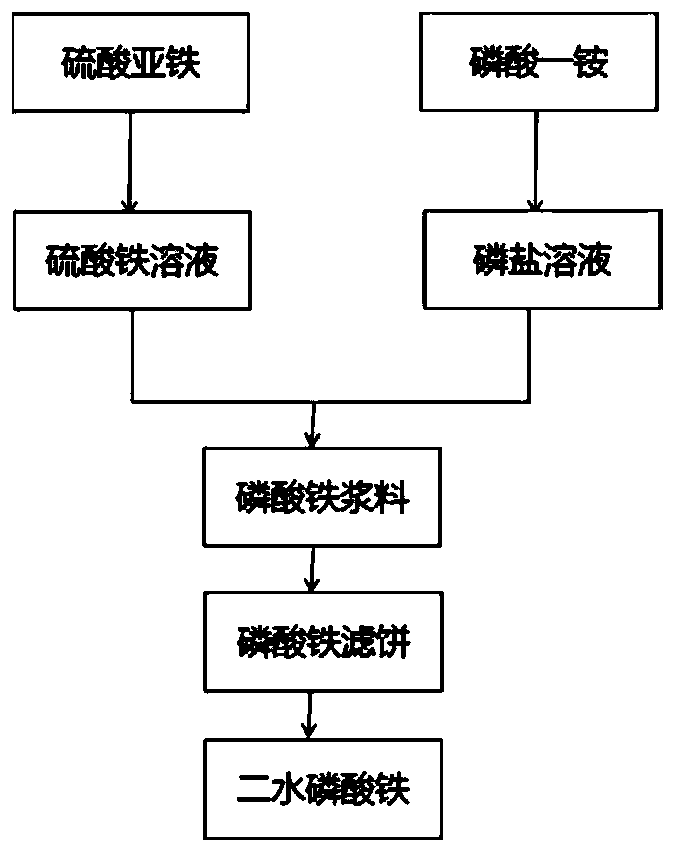

[0022] Embodiments of the present invention are: a preparation method of flaky ferric phosphate dihydrate, such as figure 1 shown, including the following steps:

[0023] (1) Weigh 834g of ferrous sulfate and dissolve it in 1.5L of water, add 58.8g of sulfuric acid and 270g of hydrogen peroxide, and after the ferrous sulfate is completely oxidized into ferric sulfate, set the volume to 2L;

[0024] (2) Take by weighing 36.24g sodium metaaluminate and be dissolved in 500ml water;

[0025] (3) Weigh 345.09g of monoammonium phosphate and add water to dissolve it, add the sodium metaaluminate solution in (2) to the monoammonium phosphate solution, add water to make the volume to 2L;

[0026] (4) Add the ferric sulfate solution in (1) into the reaction kettle as the reaction bottom liquid, set the stirring speed as 200r / min, and inject the monoammonium phosphate solution with sodium metaaluminate in (3) into the reactor with a peristaltic pump Reactor; feeding time is 30min;

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com