A method for powder enhanced biochemical water treatment

A technology of water treatment and powder, which is applied in the direction of biological water/sewage treatment, special compound water treatment, oxidation treatment of sludge, etc. It can solve the problems of unable to improve the quality of effluent water, unable to improve the sludge of sewage treatment equipment, and increasing the settling capacity. , to achieve the effect of increasing microbial concentration, fast sedimentation rate, and improving effluent water quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

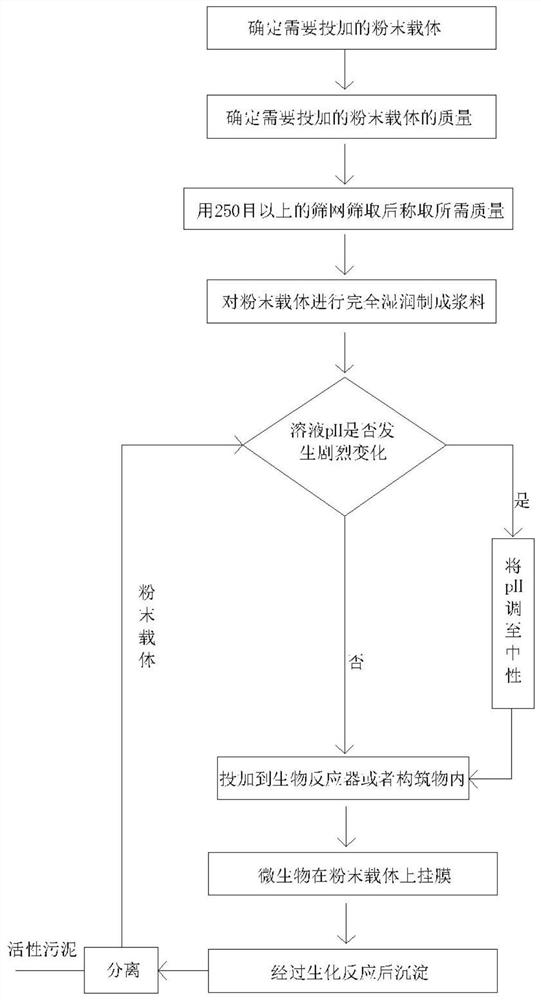

Method used

Image

Examples

Embodiment 1

[0037] A method for powder enhanced biochemical water treatment, comprising the following steps:

[0038](1) Sewage water quality is pH: 6.83-7.12, COD mass concentration: 170-210mg / L, TN mass concentration: 24-35mg / L, diatomaceous earth is intended to be used as the powder carrier for microbial loading, and the device process is "secondary A / O+ powder enhanced biochemical water treatment + sedimentation tank". The total effective volume in the device is measured to be 14m 3 , the inflow flow rate is 1m 3 / h, dosing according to the powder carrier dosage concentration of 8g / L, the calculated diatomite required to be added is 120Kg, sieved with a 300-mesh sieve to obtain 120Kg of diatomite, soak the diatomite for more than 24 hours, and make the silicon The algae earth no longer agglomerates and floats up;

[0039] (2) Since the pH of the slurry will drop sharply after adding diatomite, other alkaline substances such as fly ash or sodium hydroxide can be added to restore the...

Embodiment 2

[0044] A method for powder enhanced biochemical water treatment, comprising the following steps:

[0045] (1) The sewage water quality is pH: 6.59-7.68, COD mass concentration: 150-290mg / L, TN mass concentration: 27-41mg / L, diatomaceous earth is intended to be used as the powder carrier for microbial loading, and the device process is "SBR process +Powder enhanced biochemical water treatment", the total effective volume in the device is measured to be 8m 3 , according to the powder carrier dosing concentration of 6g / L, the calculated diatomite required to be added is 48Kg, and 48Kg of diatomite is obtained by sieving with a 250-mesh sieve;

[0046] (2) Add diatomaceous earth directly to an effective volume of 8m 3 In the cylindrical equipment, turn on the mixer and aeration equipment to evenly distribute the diatomite into the cylindrical equipment, and at the same time make the diatomite completely absorb moisture, and there are no floating particles on the liquid surface; ...

Embodiment 3

[0051] A method for powder enhanced biochemical water treatment, comprising the following steps:

[0052] (1) The sewage water quality is pH: 6.51-7.52, COD mass concentration: 190-270mg / L, TN: 24-38mg / L, it is intended to use activated carbon as the powder carrier for microbial loading, and the device process is "A / O+powder strengthening Biochemical water treatment + sedimentation tank", the total effective volume of the structure is measured to be 500m 3 , dosing according to the concentration of powder carrier 2g / L, the calculated required dosage of activated carbon is 2000Kg, sieve 2000Kg of activated carbon with a 250-mesh sieve, soak the activated carbon for more than 24 hours until it completely absorbs moisture;

[0053] (2) Add activated carbon directly to an effective volume of 500m 3 In the structure, turn on the mixer and aeration equipment to distribute the activated carbon evenly into the cylindrical equipment. Due to the large dosage, it can be placed at multip...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com