Silane coupling agent, preparation method and application thereof

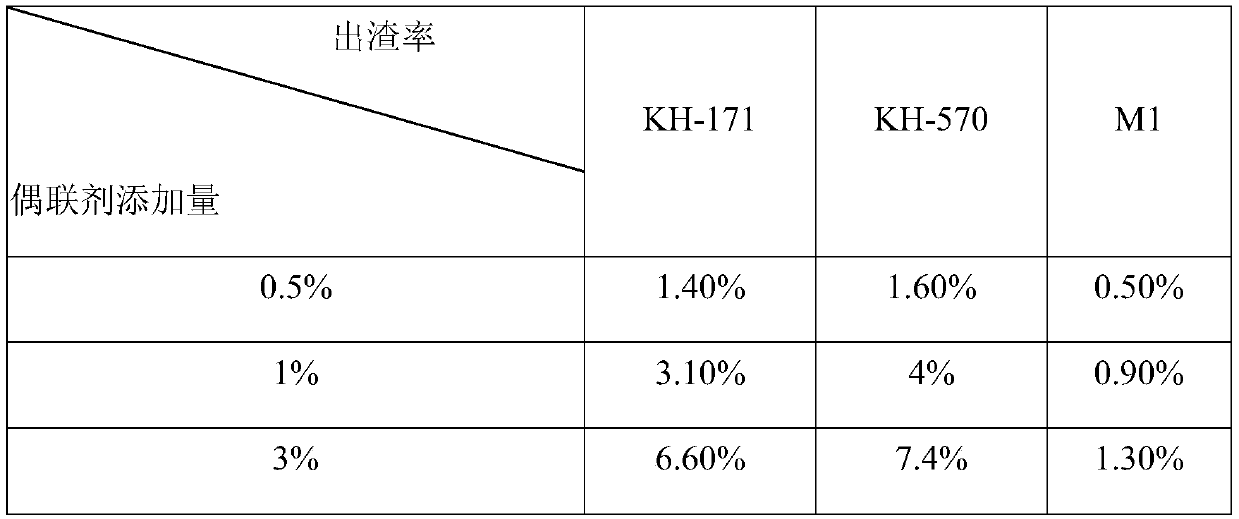

A technology of silane coupling agent and vinyltrichlorosilane, which is applied in the field of silane coupling agent and its preparation, can solve problems such as instability of acrylic emulsion, improve storage stability, reduce slag rate, and improve paint film performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

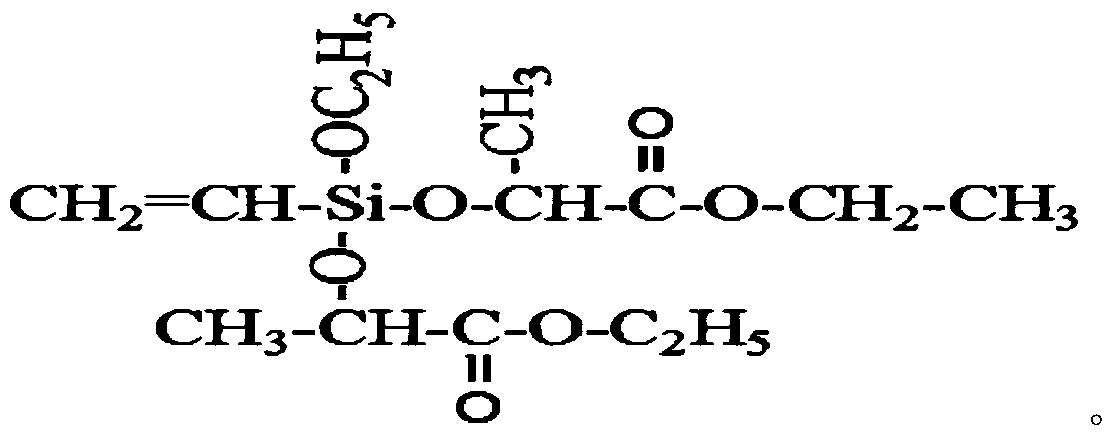

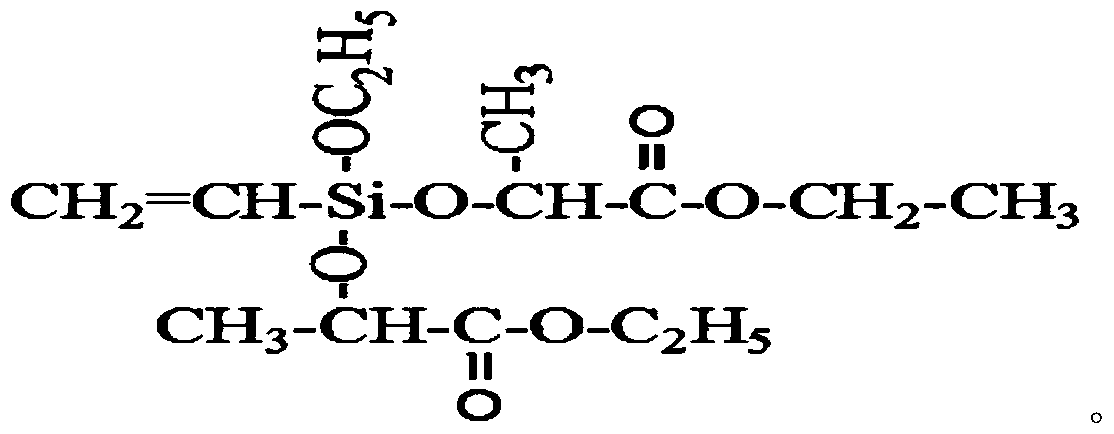

Image

Examples

Embodiment 1

[0029] (1) Carry out feeding reaction according to the molar ratio of vinyltrichlorosilane and ethanol as 1:1.1: first add ethanol to the reaction kettle, heat it to 80°C to make it slightly boiling, and then add it at a rate of 3.8g / min Slowly add vinyl trichlorosilane dropwise from the top of the packed tower to make the two fully contact and react in the tower. After the dropwise addition is completed, keep the reaction at 100°C for 2 hours. , to obtain intermediate C 2 h 3 Si(OC 2 h 5 )Cl 2 ;

[0030] (2) Carry out feeding reaction according to the molar ratio of vinyltrichlorosilane and ethyl lactate as 1:2: first add ethyl lactate to the reaction kettle, heat to slight boiling, and then mix the intermediate obtained in step (1) with 6.6 The dropping rate of g / min is dripped into the reaction kettle from the top of the tower, and after the dropping is completed, it is incubated and reacted at 160°C for 4 hours. During the reaction, the hydrochloric acid produced by t...

Embodiment 2

[0033] (1) Feed reaction according to the molar ratio of vinyltrichlorosilane and ethanol as 1:1.2: first add ethanol to the reaction kettle, heat it to 80°C to bring it into a slightly boiling state, and then drop it at a rate of 3.8g / min from Slowly add vinyl trichlorosilane to the top of the packed tower to make it fully contact and react in the tower. After the dropping is completed, keep it warm at 100°C for 2 hours. Body C 2 h 3 Si(OC 2 h 5 )Cl 2 ;

[0034] (2) Carry out feeding reaction according to the molar ratio of vinyltrichlorosilane and ethyl lactate as 1:2: first add ethyl lactate to the reaction kettle, heat to slight boiling, and then mix the intermediate obtained in step (1) with 6.6 The dropping rate of g / min is dripped into the reaction kettle from the top of the tower, and after the dropwise addition is completed, it is incubated at 150°C for 5 hours. During the reaction, the hydrochloric acid produced by the reaction is introduced into 10wt% ammonia w...

Embodiment 3

[0037] (1) Feed reaction according to the molar ratio of vinyltrichlorosilane and ethanol as 1:1.2: first add ethanol to the reaction kettle, heat it to 80°C to bring it into a slightly boiling state, and then drop it at a rate of 3.8g / min from Slowly add vinyl trichlorosilane to the top of the packed tower to make it fully contact and react in the tower. After the dropping is completed, keep it warm at 100°C for 2 hours. Body C 2 h 3 Si(OC 2 h 5 )Cl 2 ;

[0038] (2) Carry out feeding reaction according to the molar ratio of vinyltrichlorosilane and ethyl lactate as 1:2: first add ethyl lactate to the reaction kettle, heat to slight boiling, and then mix the intermediate obtained in step (1) with 6.6 The dropping rate of g / min is dripped into the reaction kettle from the top of the tower, and after the dropwise addition is completed, it is incubated at 160°C for 4 hours. During the reaction, the hydrochloric acid produced by the reaction is introduced into 10wt% ammonia wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com