Preparation method of dendritic macromolecule reinforced graphene oxide paper with holes

A graphene paper and dendritic technology, applied in the field of preparation of graphene oxide paper with holes, can solve the problems of low material quality, low tensile strength, stress relaxation, etc., and achieve the effect of high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

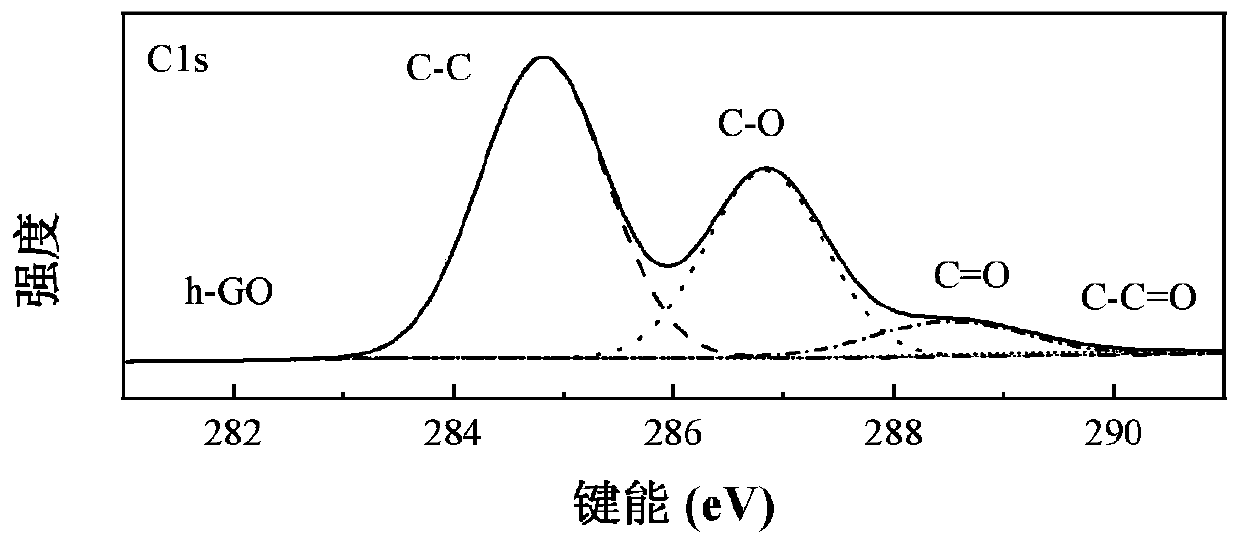

[0021] Specific embodiment one: what this embodiment records is a kind of preparation method of the graphene oxide paper with holes reinforced by dendrimers, the method is:

[0022] S1: The graphene oxide dispersion was prepared by the improved Hummers method. The concentration of graphene oxide in the dispersion was 2mg / ml-3mg / ml, and the dispersion was neutral. The specific method was as follows:

[0023] (1) Dilute 7.5mL concentrated H 2 SO 4 (98vol.%) was placed in a 100mL beaker and heated to 80°C;

[0024] (2) Add 2.5g K in sequence 2 S 2 o 8 and 2.5g P 2 o 5 , stirring continuously until the reactants are completely dissolved;

[0025] (3) Add 5g of graphite powder to the above mixture, stir to obtain a blue-black mixture, react at 80°C for 6h, cool to room temperature naturally, then dilute with distilled water, filter and wash until the pH value is about 7, remove all soluble Substance, to obtain pre-oxidized graphite, transfer the pre-oxidized graphite to a d...

specific Embodiment approach 2

[0034] Specific embodiment two: the preparation method of the graphene oxide paper with holes strengthened by a kind of dendrimers described in specific embodiment one, in S2, the volume ratio of described hydrogen peroxide solution and graphene oxide dispersion liquid is 5 -20ml: 50-70ml.

specific Embodiment approach 3

[0035] Specific embodiment three: the preparation method of a kind of dendrimer-reinforced graphene oxide paper with holes described in specific embodiment one, in S2, the specific conditions of the erosion are: stirring and heating under 100°C oil bath for 3~ 5h.

[0036] Embodiment 4: The preparation method of a dendrimer-reinforced graphene oxide paper with holes described in Embodiment 1. In S3, the polyamide-amine dendrimers and the oxide with holes The mixing ratio of the graphene dispersion liquid is 0.13mg-1.3mg: 25-50ml.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com