Veterinary clostidrium novyi exotoxin, as well as preparation method, toxin production culture medium and application

A technology of Clostridium novyi and toxin-producing medium, applied in the field of preparation of veterinary vaccines, can solve the problems of low toxin-producing efficiency of the medium, troubles of vaccine production enterprises, and low toxin-producing performance, and achieve toxin-producing The effects of stable performance, shortened preparation time, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076] Embodiment 1: Clostridium novyi toxin-producing medium screening

[0077] 1. Preparation of Clostridium novyi toxin-producing medium

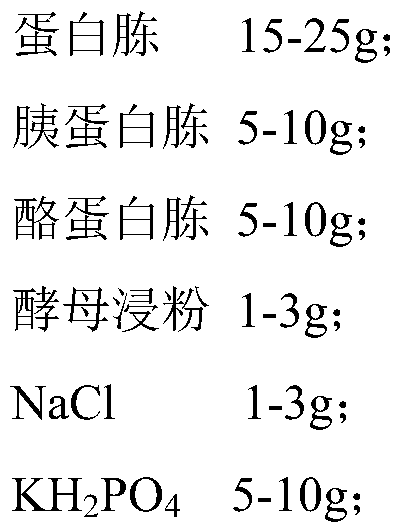

[0078] Recipe 1: Preparation of Clostridium novyi toxin-producing medium

[0079] 1.1 Add 800 mL of water for injection, add 20 g of peptone, 5 g of tryptone (purchased from Aoboxing Biotechnology Co., Ltd.), 5 g of casein peptone (purchased from Aoboxing Biotechnology Co., Ltd.), 2.5 g of yeast extract powder (purchased from OXOID), Sodium chloride 2.5g, KH2PO4 5g, to dissolve.

[0080] 1.2. Adjust the pH to 7.6-7.8 with 2mol / L NaOH.

[0081] 1.3. Add 10g of coarse dextrin (purchased from Shandong Liaocheng Ahua Pharmaceutical Co., Ltd.) and shake evenly.

[0082] 1.4. Add 100g of rust-free iron nails or iron filings after cleaning.

[0083] 1.5. Dilute to 1000ml with water for injection. Sterilize with high-pressure steam at 116°C for 30 minutes, and set aside.

[0084] Recipe 2: Preparation of Clostridium novyi toxin-producing m...

Embodiment 2

[0103] Embodiment 2: preparation Clostridium novyi toxin-producing medium

[0104] 2.1. Preparation of Clostridium novyi toxin-producing medium (biological reagent dextrin group)

[0105] Using the same preparation method as formula 2 in Example 1, the formulas listed in the following table 6 were used to prepare Clostridium novyi toxin-producing medium respectively, and its toxin-producing effect was evaluated.

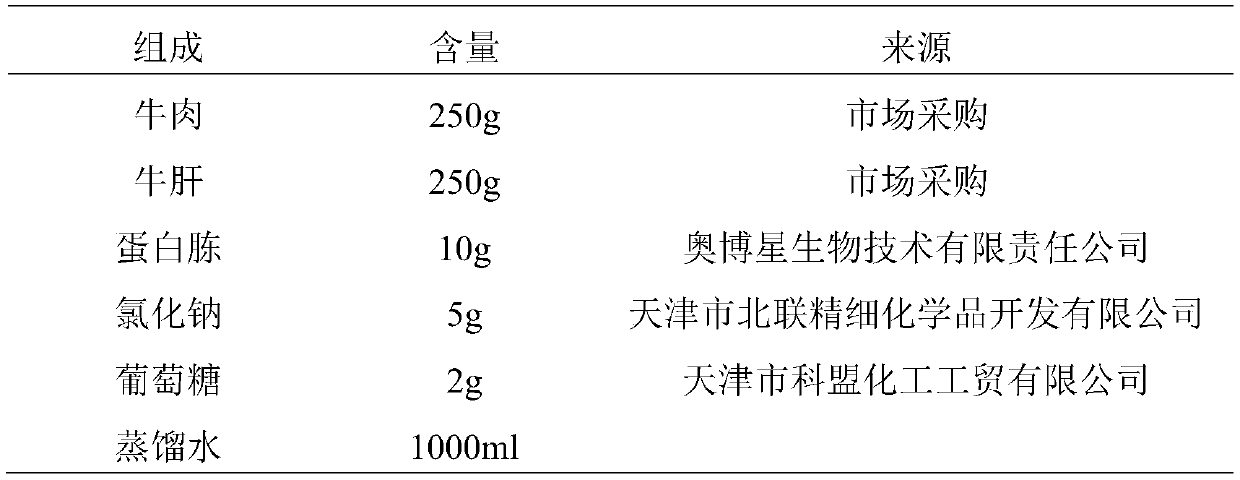

[0106] Table 6: Clostridium novyi toxin-producing medium formula (1000ml)

[0107]

[0108] In this example, the inventor prepared the Clostridium novyi toxin-producing medium according to the formula listed in the above Table 6 using the method described in the above-mentioned Example 1 for subsequent use, and then the freeze-dried Novi Open the ampoule of Clostridium strains by aseptic bursting method, extract appropriate amount of sterile nutrient broth to dissolve the freeze-dried bacteria block, inoculate into 6 test tubes of sugar-free anaerobic meat liver ...

Embodiment 3

[0116] Example 3: Preparation of Clostridium novyi exotoxin and evaluation of toxin production effect

[0117] In this embodiment, the formula 3 medium in the above-mentioned embodiment 1 was used to ferment and cultivate Clostridium novyi.

[0118] 3.1 Preparation of exotoxin from secondary seed liquid of Clostridium novyi and evaluation of toxin production effect

[0119] The primary seed liquid is inoculated in a 350ml / 500ml bottle of anaerobic meat liver soup according to the inoculum amount 5-6% (v / v), and placed at 37°C for static cultivation for 72 hours, and those who pass the pure inspection are used as the secondary seed liquid.

[0120] Qualified secondary seed liquid is inoculated in 12000 ml of Clostridium novyi toxin-producing medium according to the inoculation amount of 5-6% (v / v), and placed at 37° C. for static cultivation for 60-72 hours.

[0121] Samples were taken at 60h, 66h, and 72h of culture, and the sample bacterial liquid was centrifuged at 3000rpm / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com